Process method for preparing biological protein-rich dietary fiber and pectin simultaneously by taking potato residues as raw materials

A potato residue and biological protein technology, applied in the field of food processing, can solve problems such as waste of resources, and achieve the effects of simple process, high yield and purity, easy operation and large-scale popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

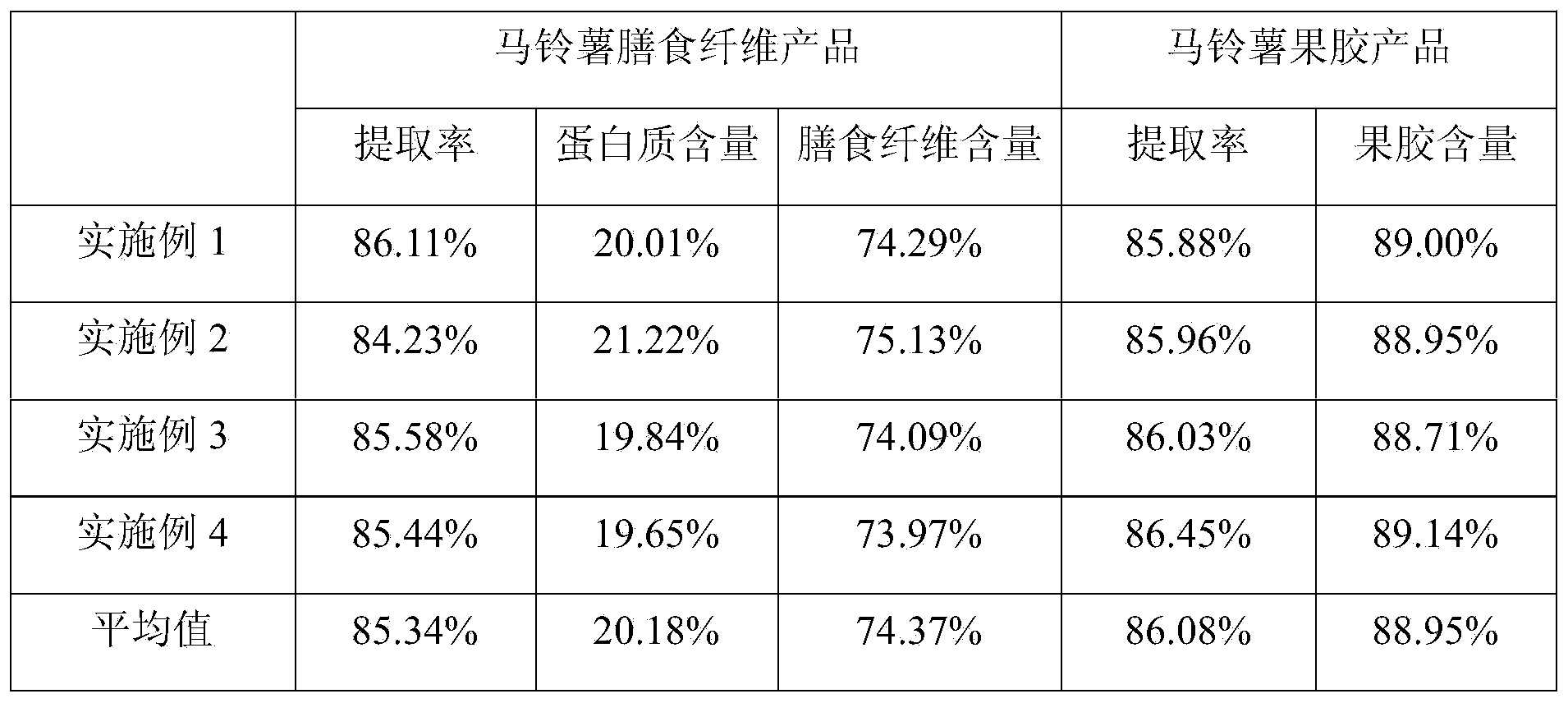

Examples

Embodiment 1

[0023] Embodiment 1: a kind of processing method that prepares dietary fiber and pectin rich in biological protein simultaneously with potato residue as raw material, comprises following processing steps:

[0024] (1) Adopt twin-screw extruder to carry out extruding puffing treatment to fresh potato residue, the water content of described potato residue is 35wt%, feed rate is 50r / min, screw speed 120r / min, extrusion temperature is divided There are 5 sections, and the extrusion temperature changes from 65-85-110-135-150°C;

[0025] (2) Add water and stir the potato slag treated in step (1) according to the weight-to-volume ratio (g / mL) of 1:10, and then use a colloid mill to grind until a solution with a uniform texture and a fine hand feeling is formed. ;

[0026] (3) Adjust the pH value of the solution treated in step (2) to 2.0, and perform ultrasonic treatment at 90°C for 45 minutes, and the power of the ultrasonic treatment is 350W;

[0027] (4) Adjust the pH value of t...

Embodiment 2

[0030] Embodiment 2: a kind of processing method of preparing dietary fiber and pectin rich in biological protein simultaneously with potato residue as raw material, is characterized in that, comprises following processing steps:

[0031] (1) Adopt twin-screw extruder to carry out extruding puffing treatment to fresh potato residues, the water content of described potato residues is 40wt%, feed rate is 40r / min, screw speed 100r / min, extrusion temperature is divided There are 5 sections, and the extrusion temperature changes from 65-85-110-135-150°C;

[0032](2) Add water and stir the potato slag treated in step (1) according to the weight-to-volume ratio (g / mL) of 1:5, and then use a colloid mill to grind until a solution with a uniform texture and a fine hand feeling is formed. ;

[0033] (3) Adjust the pH value of the solution treated in step (2) to 2.5, and perform ultrasonic treatment at 80°C for 60 minutes, and the power of the ultrasonic treatment is 500W;

[0034] (4)...

Embodiment 3

[0037] Embodiment 3: a kind of processing method of preparing dietary fiber and pectin rich in biological protein simultaneously with potato residue as raw material, it is characterized in that, comprises following processing steps:

[0038] (1) Adopt twin-screw extruder to carry out extruding puffing treatment to fresh potato residues, the water content of described potato residues is 38wt%, feed rate is 40r / min, screw speed 110r / min, extrusion temperature is divided There are 5 sections, and the extrusion temperature changes from 65-85-110-135-150°C;

[0039] (2) Add water and stir the potato slag treated in step (1) according to the weight-to-volume ratio (g / mL) of 1:8, and then use a colloid mill to grind until a solution with a uniform texture and a fine hand feeling is formed. ;

[0040] (3) Adjust the pH value of the solution treated in step (2) to 2.0, and perform ultrasonic treatment at 85° C. for 60 minutes, and the power of the ultrasonic treatment is 300 W;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com