A kind of preparation method of graphene quantum dot

A technology of graphene quantum dots and mass ratio, applied in graphene, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as low yield, unavailable raw materials, cumbersome preparation process, etc. Achieve the effect of high yield, fast preparation process and simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

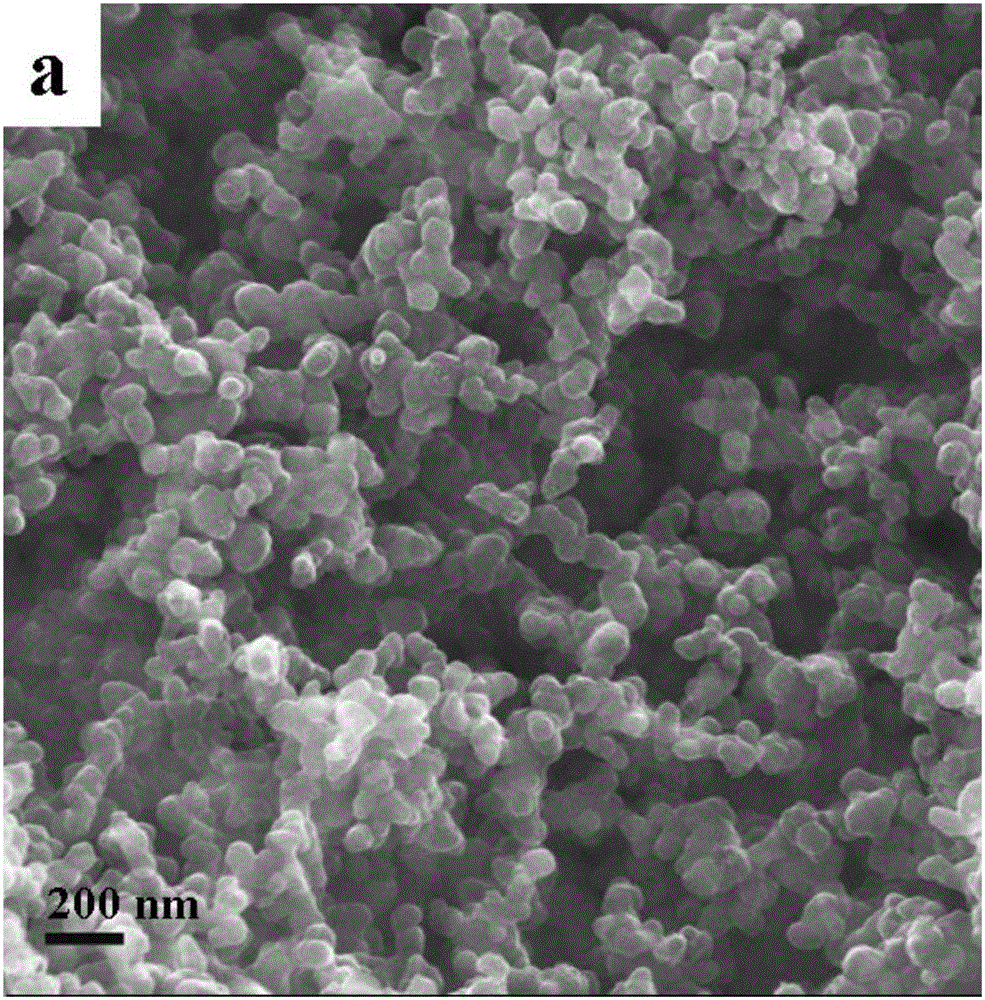

[0048] Add 50g of polytetrafluoroethylene (PTFE, 2μm) and 14g of Si powder (100nm) into cyclohexane at room temperature, stir magnetically for 1 hour to make it evenly mixed, and place it in a closed explosive device after vacuum drying; The ignition method triggers a deflagration reaction. After the reaction, the obtained carbon product is collected, and then placed in a muffle furnace for heat treatment at 300°C to remove unreacted PTFE and NaOH concentrated solution at 50°C to remove unreacted Si. After cooling, The product is repeatedly and alternately washed with ethanol and water, and dried in a vacuum oven to obtain graphene quantum dot polymerized nanoparticles.

[0049] Graphene quantum dot polymerized nanoparticles were exfoliated by the Hummer method to prepare graphene oxide quantum dots. The specific steps were: weigh 0.5g graphene quantum dot polymerized nanoparticles, add 12mL concentrated sulfuric acid and 1.5g potassium permanganate under ice bath conditions ,...

Embodiment 2

[0054] Add 50g of polytetrafluoroethylene (PTFE, 2μm) and 42g of Si powder (100nm) into cyclohexane at room temperature, stir magnetically for 1 hour to make it evenly mixed, and place it in a closed explosive device after vacuum drying; other steps With embodiment 1.

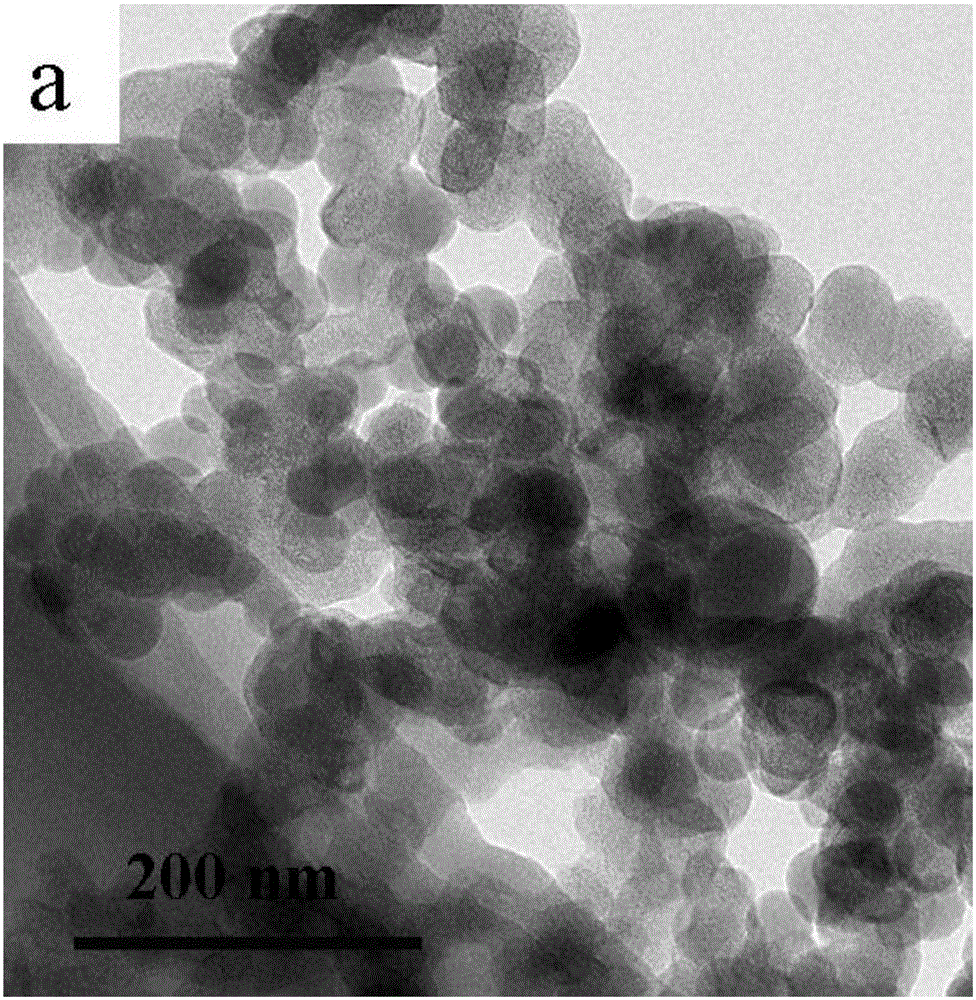

[0055] Figure 10 It is a high-resolution transmission electron microscope photo of the prepared graphene quantum dot polymerized nanoparticles. It can be seen from the photo that the carbon material prepared by the deflagration method is composed of graphene quantum dots, with a size of about 20nm and a thickness of about 5 layer graphite structure.

Embodiment 3

[0057] Add 50g polytetrafluoroethylene (PTFE, 300nm) and 14g Si powder (100nm) into cyclohexane at room temperature, stir magnetically for 1 hour to make it evenly mixed, and place it in a closed explosive device after vacuum drying; other steps With embodiment 1.

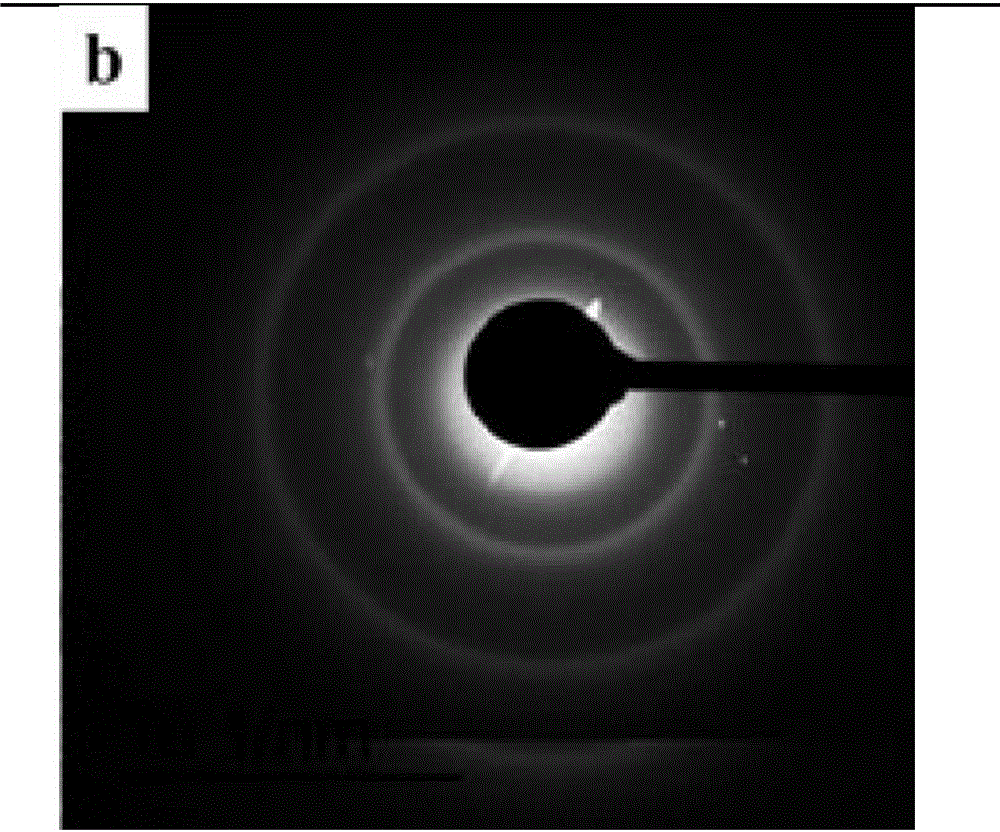

[0058] Figure 11 It is a high-resolution transmission electron microscope photo of the prepared graphene quantum dot polymerized nanoparticles. From the photo, it can be seen that the graphene quantum dot prepared by reducing the size of the reactant has a slightly larger size, about 50nm, and a thickness of about It is a 15-layer graphite structure, which may be due to the small size of the reactant ions leading to an increase in the reaction rate, resulting in an increase in the temperature of the deflagration flame and a prolongation of the growth process of carbon atoms, so that the size of the grown graphene quantum dots has a increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com