Method for super-rapidly preparing high-performance high-silicon-manganese thermoelectric material

A technology of thermoelectric materials and high manganese silicon, which is applied in the direction of thermoelectric device node lead-out materials, metal silicides, etc., can solve the problems of high equipment requirements, long preparation cycle, and difficulty in large-scale application, and achieve low equipment requirements, The effect of abundant reserves and shortened cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A new method for ultra-fast preparation of high-performance high-manganese-silicon thermoelectric materials, which includes the following steps:

[0031] 1) Press MnSi 1.75 The stoichiometric ratio of each atom is weighed Mn powder, Si powder, total mass 2.5g, then they are ground and mixed evenly, and the uniformly mixed powder is pressed into a cylindrical block block with a diameter of 15mm (40MPa holding pressure for 15min) ;

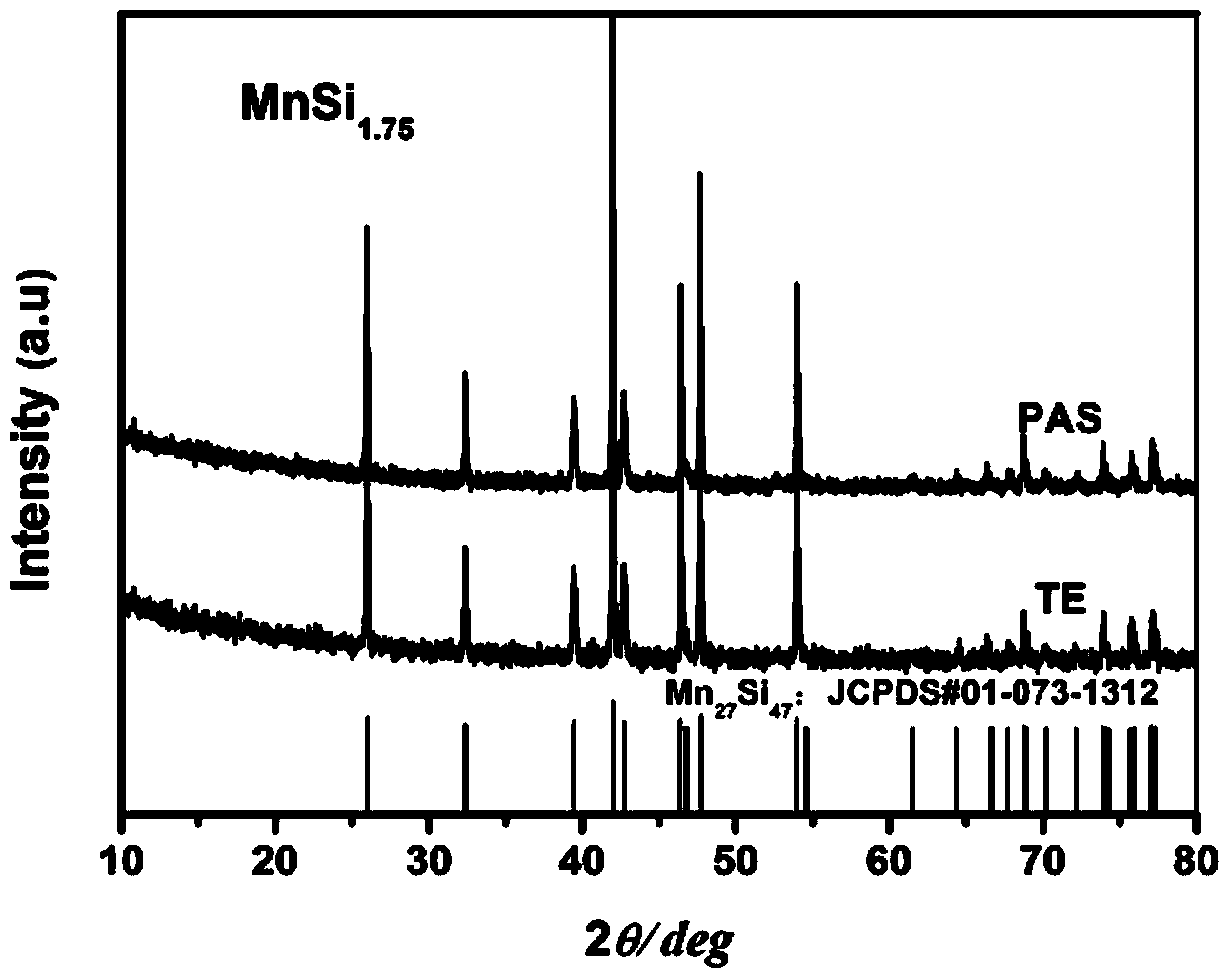

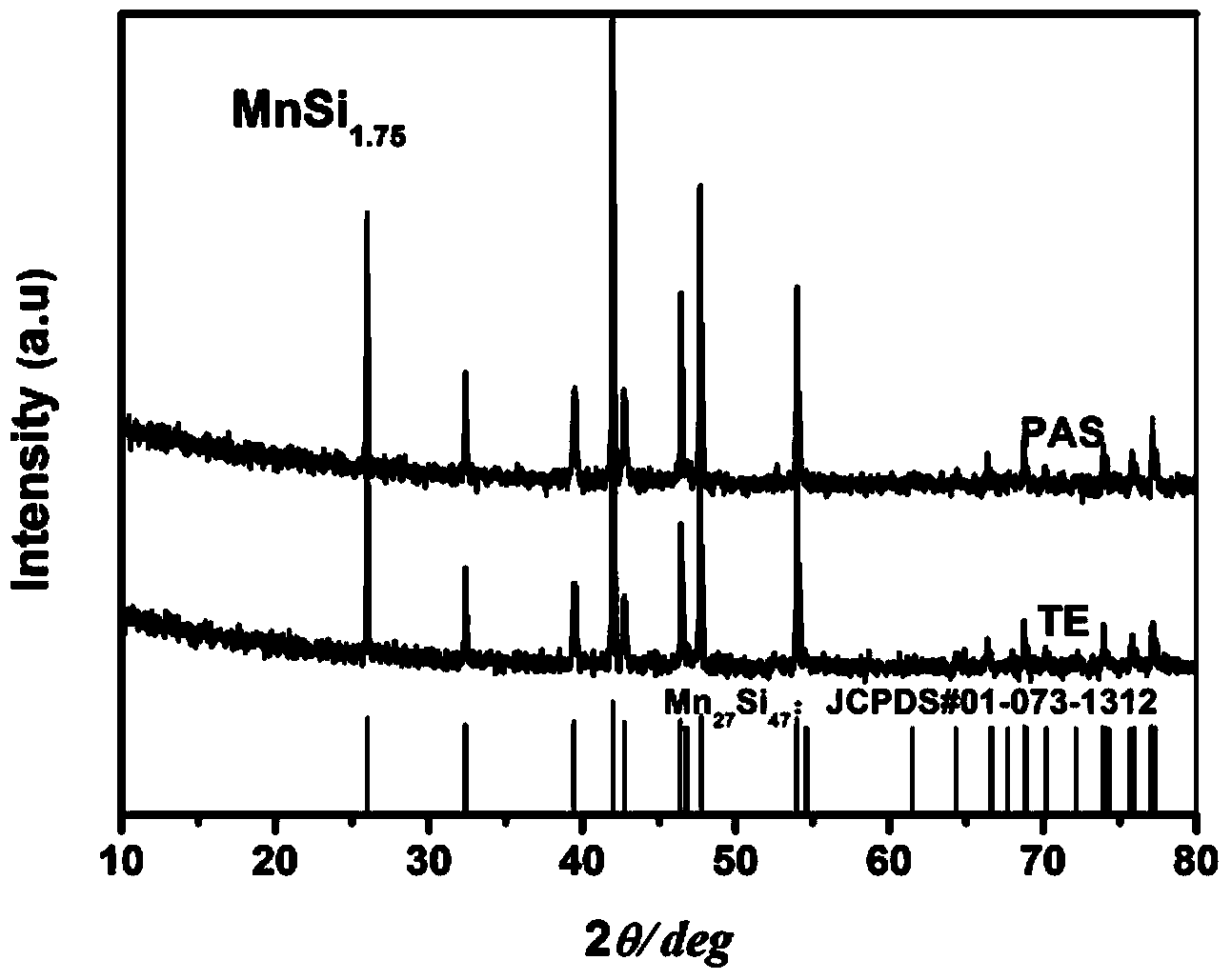

[0032] 2) Seal the block obtained in step 1) into a vacuum quartz glass tube, and put it into a vertical furnace with an overall temperature of 1180°C for thermal explosion reaction (TE, Thermal Explosion), take it out after 10 minutes and let it cool naturally;

[0033] 3) Grind the above-mentioned product into powder, carry out discharge plasma activated sintering (PAS, Plasma Activated Sintering), put the powder into a graphite mold with a diameter of 15mm and compact it, and then carry out under the conditions of a vacuum of less than 10...

Embodiment 2

[0036] A new method for ultra-fast preparation of high-performance high-manganese-silicon thermoelectric materials, which includes the following steps:

[0037] 1) Press MnSi 1.75 The stoichiometric ratio of each atom is weighed Mn powder, Si powder, total mass 2.5g, then they are ground and mixed evenly, and the uniformly mixed powder is pressed into a cylindrical block block with a diameter of 15mm (40MPa holding pressure for 15min) ;

[0038] 2) Seal the block obtained in step 1) into a vacuum quartz glass tube, and put it into a vertical furnace with an overall temperature of 1237°C for thermal explosion reaction (TE, Thermal Explosion), take it out after 5 minutes and let it cool naturally;

[0039] 3) Grind the above-mentioned product into powder, carry out discharge plasma activated sintering (PAS, Plasma Activated Sintering), put the powder into a graphite mold with a diameter of 15mm and compact it, and then carry out under the conditions of a vacuum of less than 10P...

Embodiment 3

[0042] A new method for ultra-fast preparation of high-performance high-manganese-silicon thermoelectric materials, which includes the following steps:

[0043] 1) According to Mn(Al 0.0015 Si 0.9985 ) 1.75 The stoichiometric ratio of each atom, that is, the stoichiometric ratio of Mn, Al and Si is 1:(0.0015*1.75):(0.9985*1.75) to weigh Mn powder, Al powder, Si powder, total mass 2.5g, then They are ground and mixed evenly, and the uniformly mixed powder is pressed into a cylindrical block block with a diameter of 15mm (40MPa holding pressure for 15min);

[0044] 2) Seal the block obtained in step 1) into a vacuum quartz glass tube, and put it into a vertical furnace with an overall temperature of 1237°C for thermal explosion reaction (TE, Thermal Explosion). After 10 minutes of reaction, take it out and let it cool naturally;

[0045] 3) Grind the above-mentioned product into powder, carry out discharge plasma activated sintering (PAS, Plasma Activated Sintering), put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com