Preparation method of silver coated aluminum alloy powder for conductive filler

A technology of alloy powder and powder, applied in the field of electroless plating, which can solve problems such as easy agglomeration, failure of plating solution decomposition, and difficult plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

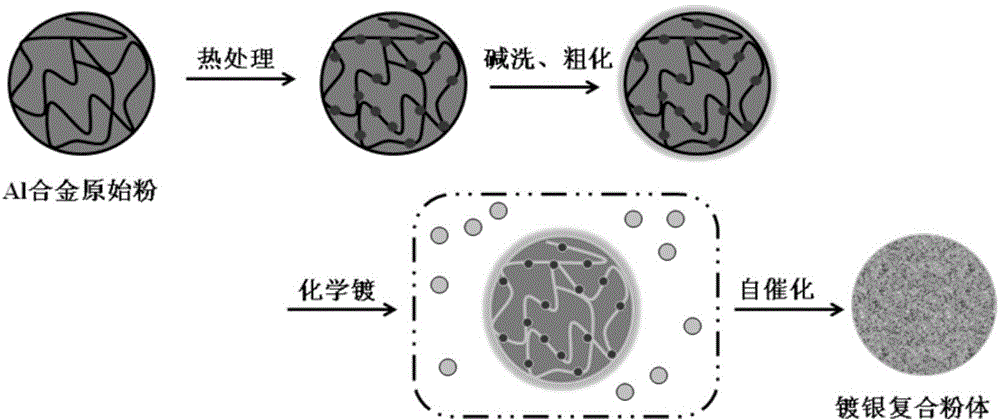

Method used

Image

Examples

Embodiment example 1

[0022] 1) Preparation of Al-La alloy powder: Alloy powder with an alloying element La content of 0.3 wt% was prepared by vacuum atomization method.

[0023] 2) Heat treatment before Al-La alloy powder plating, the heat treatment temperature is 100°C and the time is 2h.

[0024] 3) Pretreatment of Al-La alloy powder: Take 2g of alloy powder, corrode it with 0.02wt% NaOH solution under ultrasonic conditions, and wash it with deionized water 3 times when bubbles are seen.

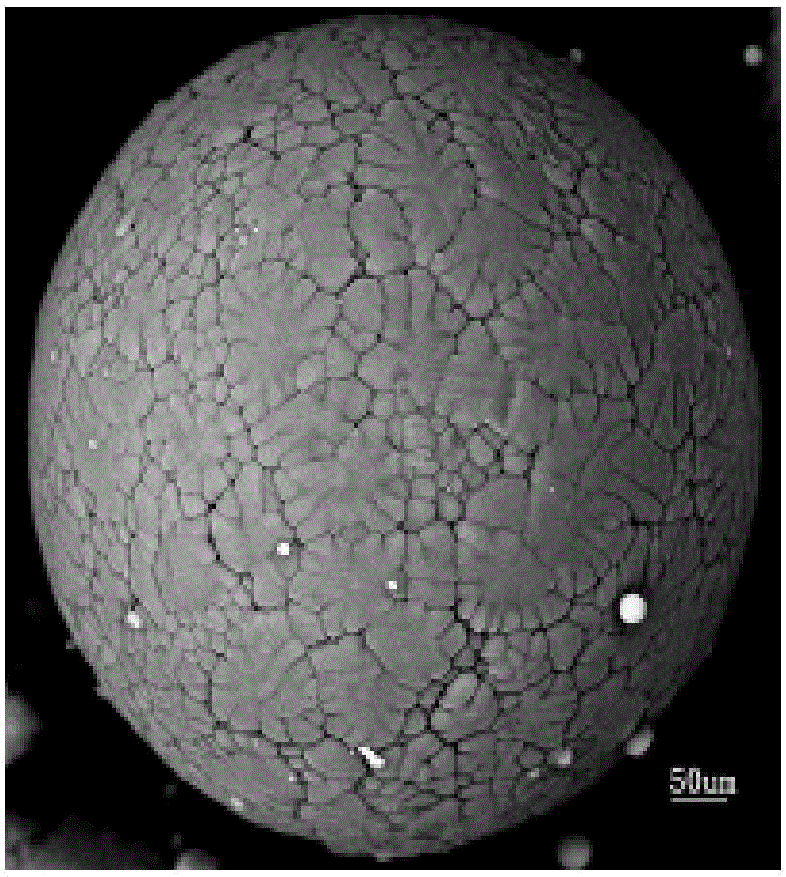

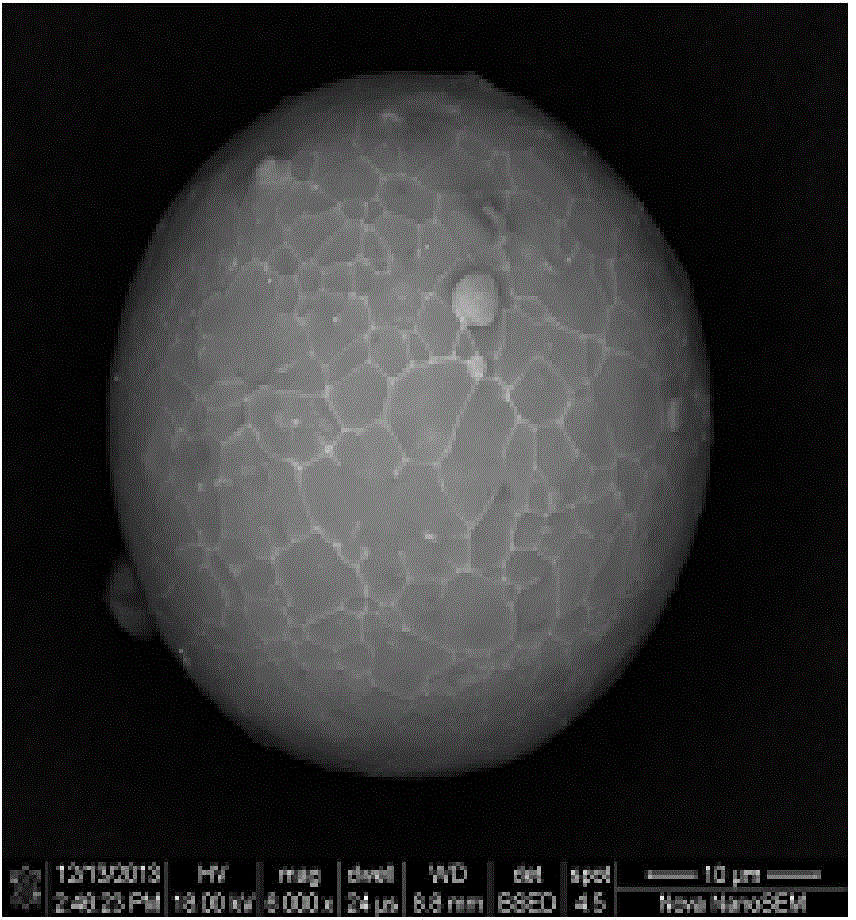

[0025] 4) Direct electroless silver plating of Al-La alloy powder: under the condition of room temperature and normal pressure, place the alloy powder after roughening treatment in the previous step in 100ml of electroless silver plating reducing solution, the reducing solution is composed of glucose (30g / L) , thiourea (2mg / L), potassium sodium tartrate (3g / L), absolute ethanol (50ml) and the rest are composed of deionized water, silver salt is silver ammonia solution (20g / L) 50ml, under stirring conditions T...

Embodiment example 2

[0027] 1) Preparation of Al-Zn alloy powder: an alloy powder with an alloying element Zn content of 1 wt% was prepared by a vacuum atomization method.

[0028] 2) Heat treatment before Al-Zn alloy powder plating, the heat treatment temperature is 150°C and the time is 1h.

[0029] 3) Pretreatment of Al-Zn alloy powder: take 2g of alloy powder, wash and corrode with NaOH solution with a concentration of 0.03wt% under ultrasonic conditions, when bubbles are seen, wash the alloy powder with deionized water 3 times.

[0030] 4) Direct electroless silver plating of Al-Zn alloy powder: under the condition of room temperature and normal pressure, the alloy powder after roughening treatment in the previous step is placed in 100ml of electroless silver plating reducing solution, and the reducing solution is composed of glucose (30g / L) , thiourea (2mg / L), potassium sodium tartrate (3g / L), absolute ethanol (50ml) and the rest are composed of deionized water, silver salt is silver ammonia...

Embodiment example 3

[0032] 1) Preparation of Al-Mg alloy powder: The alloy powder with alloying element Mg content of 2wt% was prepared by vacuum atomization method

[0033] 2) The Al-Mg alloy powder is heat treated before plating, the heat treatment temperature is 200°C and the time is 0.5h.

[0034] 3) Pretreatment of Al-Mg alloy powder: take 2g of alloy powder, wash and corrode it with 0.04wt% NaOH solution under ultrasonic conditions, when bubbles are seen, wash the alloy powder three times with deionized water.

[0035] 4) Direct electroless silver plating of Al-Mg alloy powder: under the condition of room temperature and normal pressure, place the alloy powder after roughening treatment in the previous step in 100ml of electroless silver plating reducing solution, the reducing solution is composed of glucose (30g / L) , thiourea (2mg / L), potassium sodium tartrate (3g / L), absolute ethanol (50ml) and the rest are composed of deionized water, silver salt is silver ammonia solution (20g / L) 50ml, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com