1.6-micron wave band pulse type single-frequency linear polarization laser

A laser and linear polarization technology, which is applied in the field of 1.6μm-band pulsed single-frequency linear polarization lasers, can solve the problems of difficult to further increase the output single pulse energy, limited fiber nonlinear effects, etc., so as to avoid nonlinear effects and be easy to control , High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

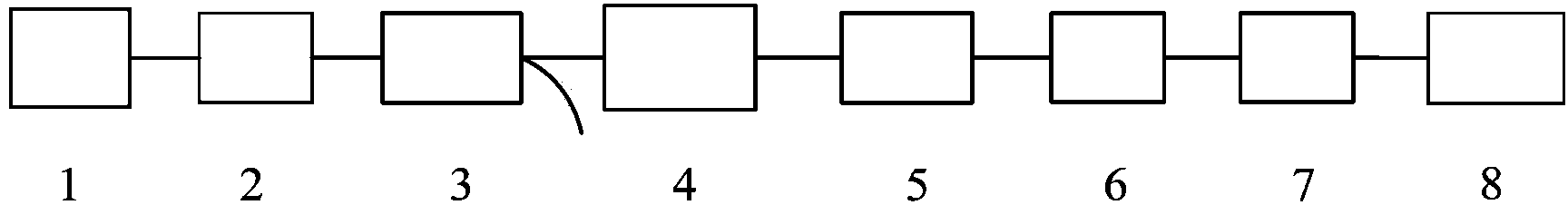

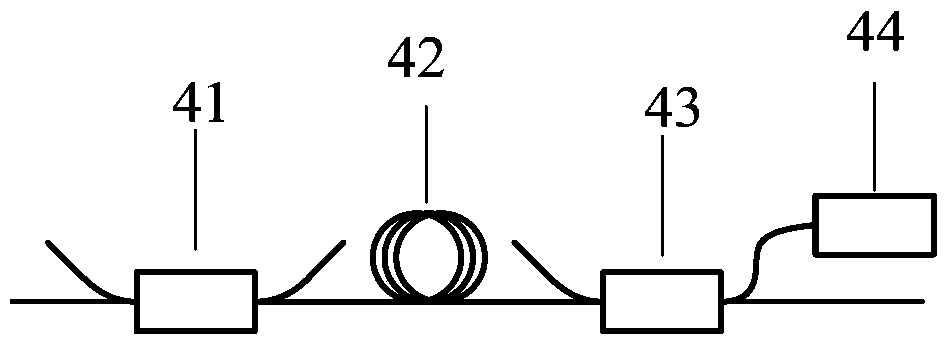

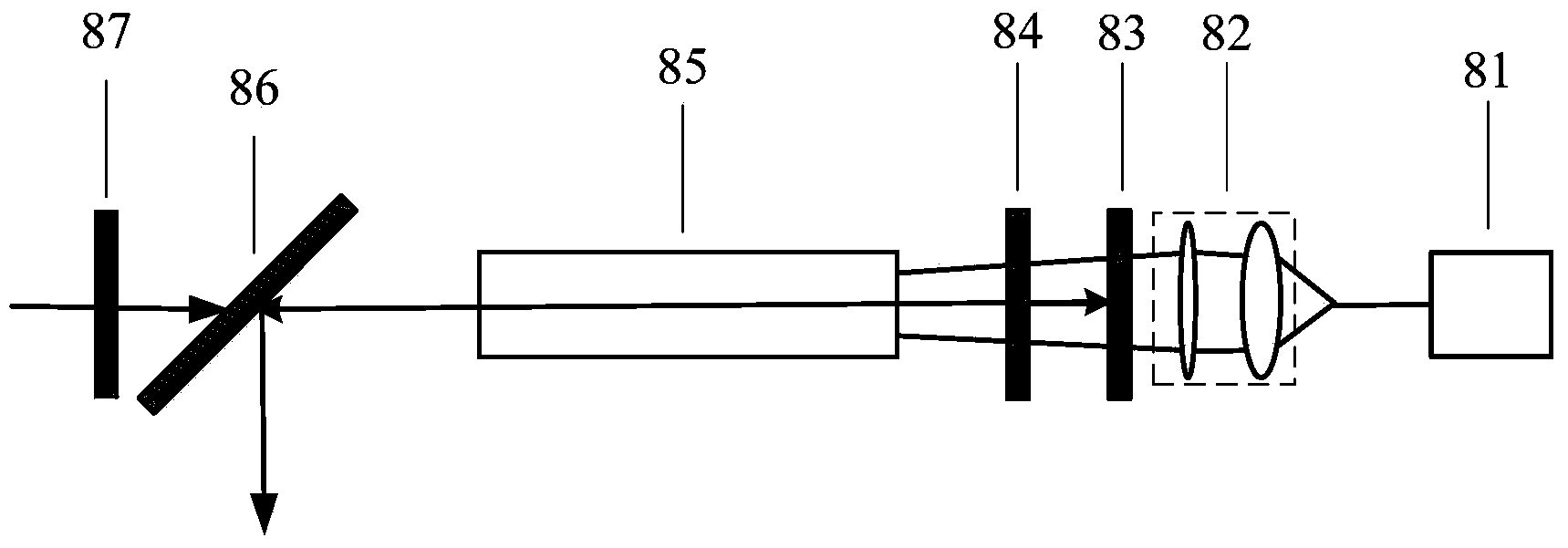

[0023] The seed source laser 1 selects a linearly polarized DFB laser with a center wavelength of 1645nm and a pigtail output. After the seed isolator 2, the beam splitter 3 separates part of the light as the local oscillator light in coherent detection, and the rest of the seed light is used as the signal light. It is coupled into a polarization-maintaining Raman gain fiber 42 in a quartz matrix through a wavelength division multiplexer 41 . The peak value of the Raman gain spectrum of the quartz-matrix polarization-maintaining Raman gain fiber corresponds to about 13.4THz, and the calculated wavelength of the pump light is 1532nm. Therefore, the first pump source 44 is selected as the center wavelength of 1532nm, and the repetition rate and pulse width are adjustable. 1. The polarization-maintaining erbium-ytterbium co-doped pulsed fiber laser with linear polarization output is pumped back through the pump beam combiner 43 . The polarization maintaining Raman gain fiber 42 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com