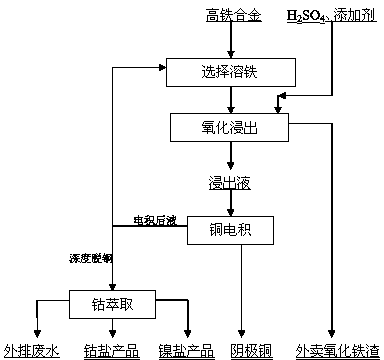

High ferroalloy treatment process

A processing technology and ferroalloy technology, applied in photography technology, photography auxiliary technology, instruments, etc., can solve the problems of low copper direct yield, high iron removal cost, increase copper extraction agent consumption, etc., and reduce the use of acid. Quantity, reduce process links, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The alloy powder with the mass percentage composition of Cu 67.87%, Co 5.71% and Fe 23.46% is placed in the liquid after electroplating according to the liquid-solid ratio of 30:1 to carry out the iron-dissolving reaction. The reaction temperature is room temperature -60 ℃, and the obtained The copper powder, alloy and solution are put into the leaching kettle for oxidative leaching. The solution is added with sulfuric acid until the acid concentration is 0.5mol / l, the operating temperature is 370K, the reaction pressure is 0.6MPa, the reaction time is 3 hours, and the amount of additives added is 5g / l. L, the components of the obtained iron slag after filtration and drying are (mass percent) Cu 0.1, Co 0.08, and Fe 50.7. The composition of the leaching solution (g / L) Cu 44.83, Co 3.77, Fe 0.04, the leaching rate of copper is over 99%, and the leaching rate of cobalt is over 99.3%.

[0016] The sulfate solution of copper, cobalt and nickel containing Fe0.04g / L was elect...

Embodiment 2

[0019] The high-iron copper-cobalt alloy powder with the mass percentage composition of Cu 18%, Co 12% and Fe 65% is placed in the liquid after electroplating according to the liquid-solid ratio of 5:1 to carry out the iron-dissolving reaction. The reaction temperature is room temperature -60 ℃. After completing the obtained alloy and the solution, enter the pressure leaching process together, add sulfuric acid to the solution until the acid concentration is 4mol / l, the operating temperature is 410K, the reaction pressure is 0.7MPa, the reaction time is 3 hours, and the amount of additives added is 15g / L to obtain The composition of the iron slag after filtration and drying is (mass percent) Cu 0.08, Co 0.05, Fe55.6. The composition of the leaching solution (g / L) Cu 44.83, Co 3.77, Fe 0.04, the leaching rate of copper is over 99%, and the leaching rate of cobalt is over 99.3%.

[0020] The sulfate solution containing Fe 0.05g / L copper, cobalt and nickel was electrolytically de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com