Process for the production of furfural

A kind of technology of furfural and reaction vessel, applied in the field for preparing furfural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

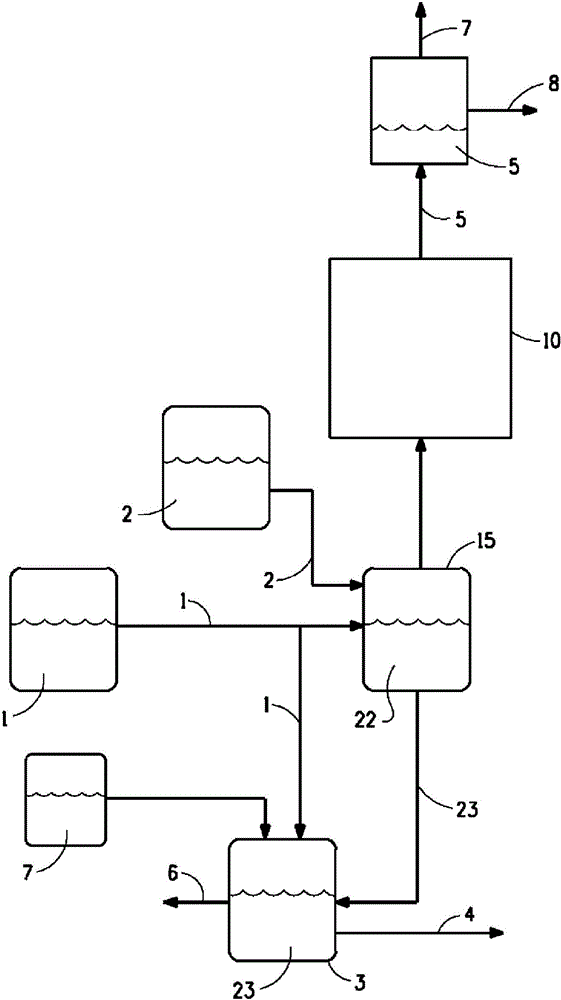

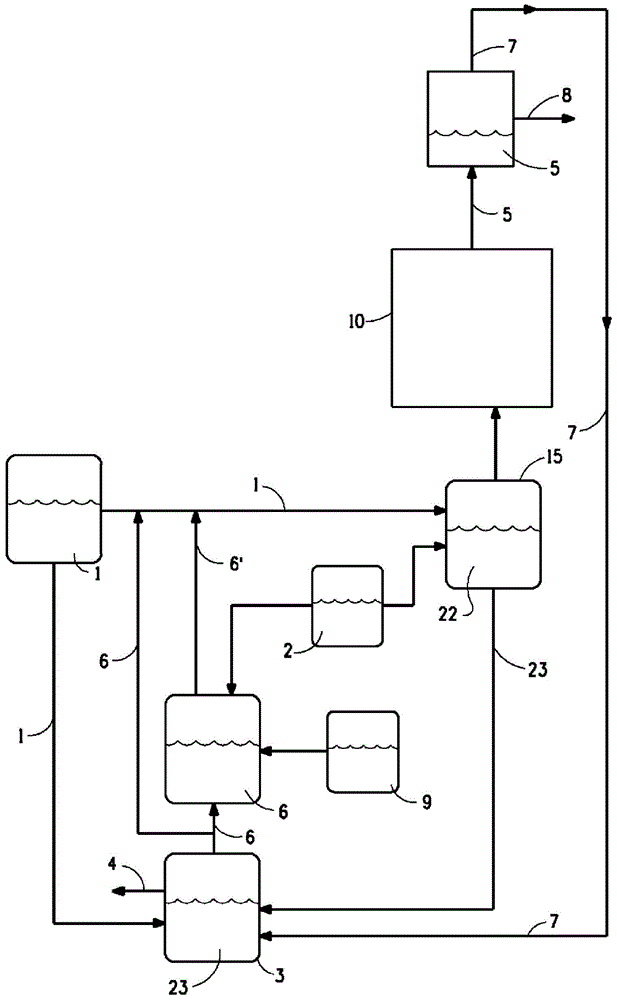

Method used

Image

Examples

example

[0088] The methods described herein are illustrated in the following examples. From the above discussion and these Examples, one skilled in the art can ascertain the characteristics of this invention, and without departing from the spirit and scope thereof, can make various changes and modifications of the invention to adapt it to different usage and conditions .

[0089] abbreviation

[0090] The meanings of the abbreviations are as follows: "BP" refers to the boiling point at a pressure of 0.101 MPa, "cm" refers to centimeters, "DMSO" refers to dimethyl sulfoxide, "MP" refers to melting point, "FF" refers to furfural, "g" means grams, "h" means hours, "HPLC" means high pressure liquid chromatography, "m" means meters, "min" means minutes, "mL" means milliliters, and "mm" means mm, "MPa" refers to megapascals, "PTFE" refers to poly(tetrafluoroethylene), "rpm" refers to revolutions per minute, "wt%" refers to weight%, "μL" refers to microliters and " μm" means micrometers...

example 1

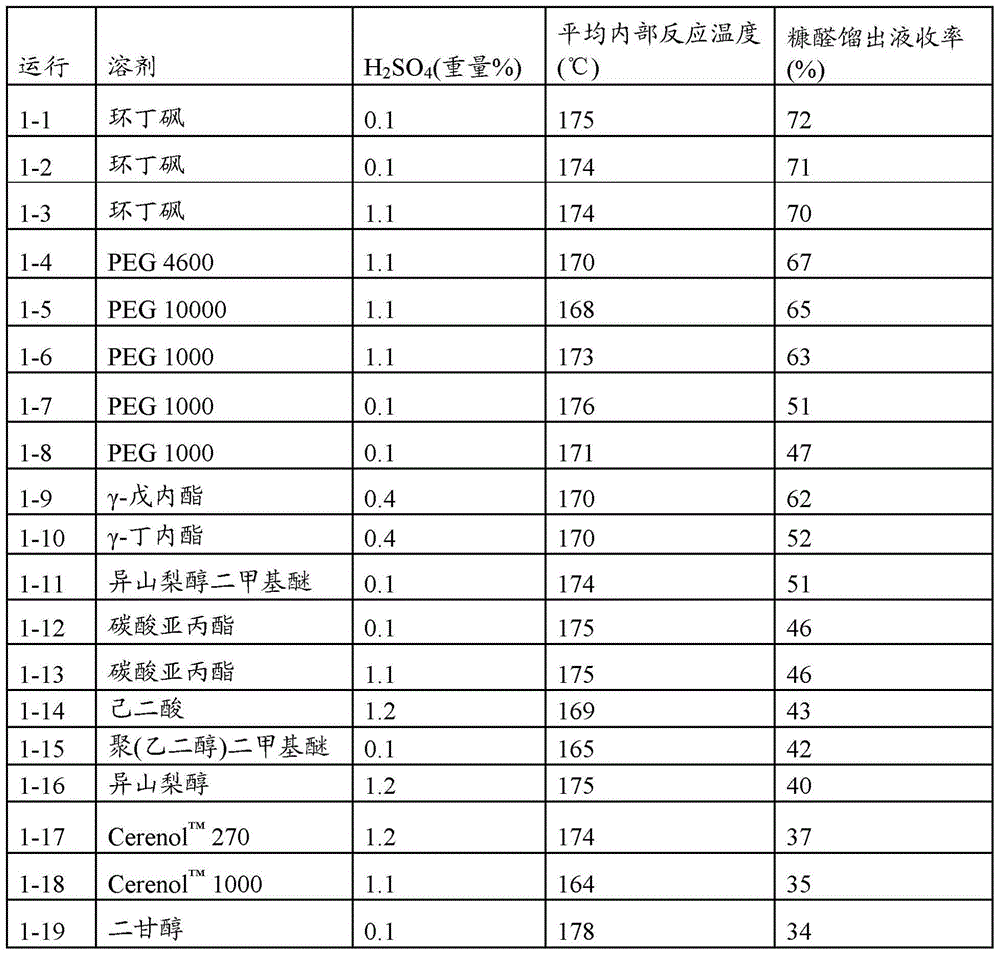

[0096] Example 1: Furfural yield in various solvents

[0097] The solvents used in this example are described in Table 1.

[0098] Table 1.

[0099] name

CAS registration number

BP(°C)

MP(°C)

126-33-0

285

20

PEG (polyethylene glycol) 4600

25322-68-3

>200

°

PEG10000

25322-68-3

>200

63

PEG1000

25322-68-3

>200

39

5306-85-4

234

°

108-32-7

240

-55

124-04-9

338

154

Poly(ethylene glycol) dimethyl ether

24991-55-7

>250

652-67-5

>200

Cerenol TM 250 (poly-1,3-propanediol)

345260-48-2

>200

Cerenol TM 1000 (poly-1,3-propanediol)

345260-48-2

>200

111-46-6

245

-10

Glycerin

56-81-5

290

20

80-05-...

example 2

[0108] Example 2: Preparation of furfural with sulfolane as solvent

[0109] The conversion of xylose to furfural was also characterized by the use of sulfolane as solvent and sulfuric acid as acid catalyst. A series of experimental runs were performed using variations of the following conditions: 0.1 to 1.5% by weight sulfuric acid based on the weight percent of sulfolane; 5 to 25% by weight xylose in water; and an average reaction temperature of 140 to 190°C during the experiments ; The rate of addition of aqueous xylose solution was 0.1 to 0.4 mL / min.

[0110] For this set of reactions, the following experimental variables were kept constant: the solvent was sulfolane, the mass of the solvent was 5 g, the stirring rate was about 500 rpm, the reaction time was 40 min, and the reaction setup and analysis method were as described in Example 1.

[0111] The xylose solution was added at a defined rate at a specified reaction temperature to a reaction vessel containing sulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com