Beverage prepared from purple corn and wheat germ and processed by ultrahigh pressure and preparation method of beverage

A technology for purple corn wheat germ and corn wheat germ is applied in the field of purple corn wheat germ beverage and its preparation, which can solve the problems of waste of wheat germ resources, no use of purple corn wheat germ beverage, and difficulty in preservation, etc., so as to improve resource utilization. rate, scavenging free radicals, anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

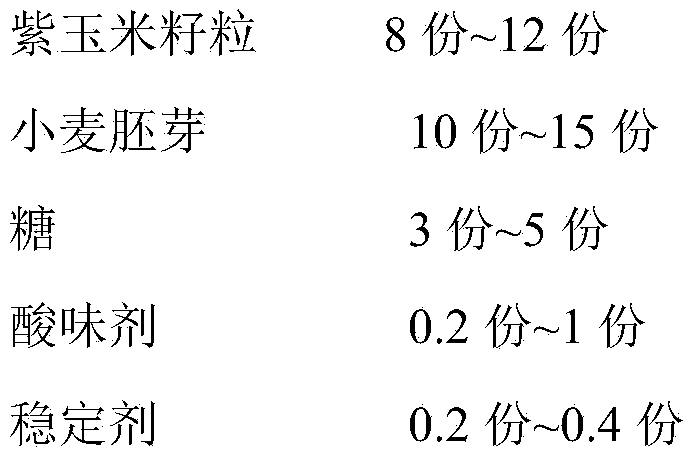

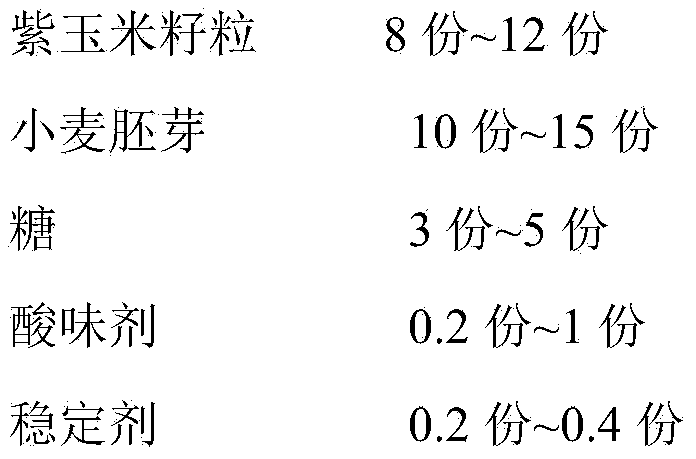

[0032] Select plump, insect-free purple corn, precook and thresh it after cleaning, weigh 80g for later use; select fresh wheat germ for microwave drying, the thickness of the treatment is 1cm, the microwave power is 400W, and the treatment time is 5min; Take 100g of the above-mentioned microwave-treated wheat germ, soak it in 500ml of pure water for 3 hours, and the soaking temperature is 30°C; mix the purple corn kernels with the wheat germ, put them into a tissue grinder, and then add 900ml of water to the colloid Refining in the mill to obtain purple corn wheat germ slurry, then gelatinize the purple corn wheat germ slurry, gelatinization temperature: 80°C, gelatinization time: 30min, add 3600U active medium temperature α- Amylase is used for enzymatic hydrolysis, the enzymatic hydrolysis time is 120min, and the enzymatic hydrolysis temperature is 55°C; the mixed slurry after enzymolysis is subjected to ultrahigh pressure treatment, the ultrahigh pressure is 100MPa, ultrahi...

Embodiment 2

[0034]Select plump, moth-free purple corn, precook and thresh it after cleaning, weigh 100g for later use; select fresh wheat germ for microwave drying, the thickness of the treatment is 2cm, the microwave power is 500W, and the treatment time is 8min; Take 120g of the above-mentioned microwave-treated wheat germ, soak it in 600ml of pure water for 4 hours, and the soaking temperature is 40°C; mix the purple corn kernels with the wheat germ, put them into a tissue grinder, and then add 1200ml of water Refining in a colloid mill to obtain purple corn wheat germ slurry, then gelatinize the purple corn wheat germ slurry, gelatinization temperature: 85°C, gelatinization time: 25min, add 4000U active medium temperature to the gelatinized slurry α-amylase is used for enzymolysis, the enzymolysis time is 160min, and the enzymolysis temperature is 60°C; the mixed slurry after enzymolysis is subjected to ultrahigh pressure treatment, the ultrahigh pressure is 150MPa, the ultrahigh press...

Embodiment 3

[0036] Select plump, moth-free purple corn, precook and thresh it after cleaning, weigh 120g for later use; select fresh wheat germ for microwave drying, the thickness of the treatment is 2cm, the microwave power is 600W, and the treatment time is 3min; Take 130g of the above-mentioned microwave-treated wheat germ, soak it in 650ml of pure water for 5 hours, and the soaking temperature is 55°C; mix the purple corn kernels with the wheat germ, put them into a tissue grinder, and then add 1500ml of water Refining in a colloid mill to obtain purple corn wheat germ slurry, then gelatinize the purple corn wheat germ slurry, gelatinization temperature: 90°C, gelatinization time: 20min, add 4500U active medium temperature to the gelatinized slurry α-amylase is used for enzymolysis, the enzymolysis time is 180min, and the enzymolysis temperature is 60°C; the mixed slurry after enzymolysis is subjected to ultrahigh pressure treatment, the ultrahigh pressure is 200MPa, the ultrahigh pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com