Raman spectrum based optical waveguide sensor

A technology of Raman spectroscopy and optical waveguide, applied in the field of optical waveguide sensors based on Raman spectroscopy, can solve problems such as bulky, complex surface functionalization, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

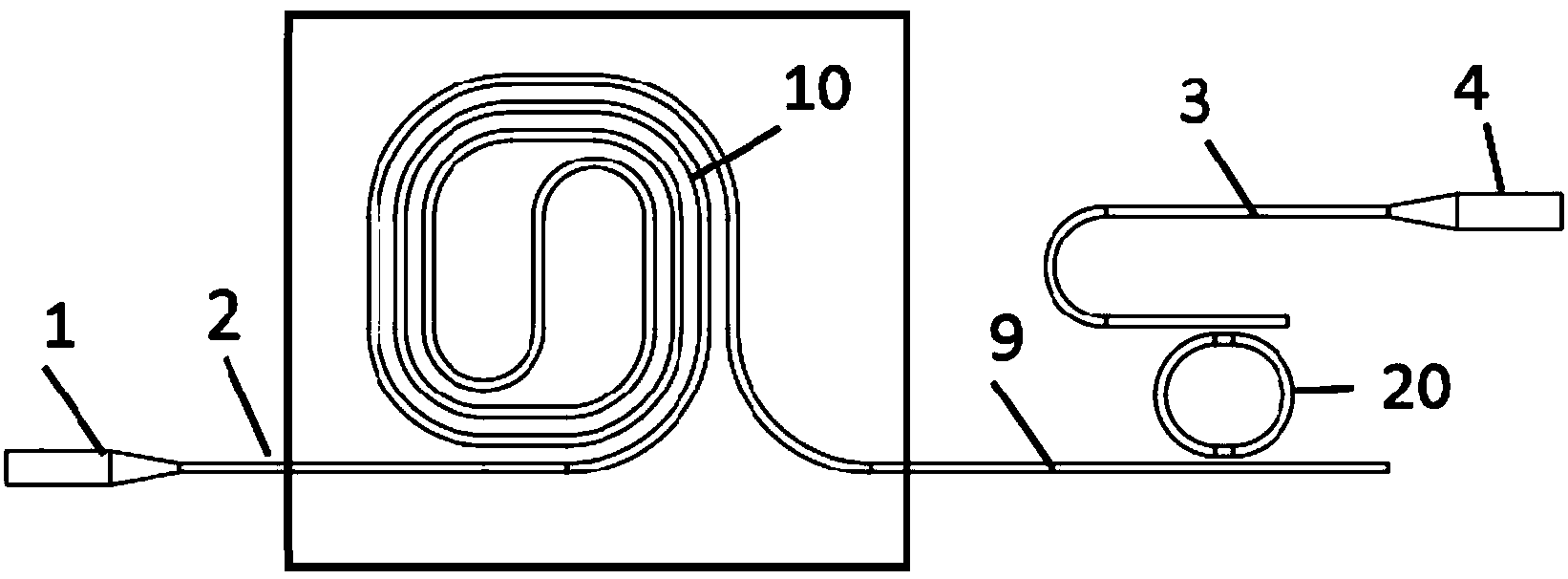

[0042] Such as figure 1 As shown, the present invention includes a wavelength tunable laser 1, an input waveguide 2, a spiral sensing waveguide 10, a connecting waveguide 9, a filter 20, an output waveguide 3 and an optical power meter 4, and the above wavelength tunable laser 1, input waveguide 2 , the spiral sensing waveguide 10 , the filter 20 , the connecting waveguide 9 , the output waveguide 3 and the optical power meter 4 are all located on the same substrate, between the waveguide lower cladding layer 5 and the waveguide upper cladding layer 6 .

[0043] The filter 20 adopts a ring resonator with a single microring structure, the optical power meter 4 adopts an integrated optical detector, and the wavelength tunable laser 1 is an integrated semiconductor wavelength tunable laser. The input waveguide 2, the helical sensing waveguide 10, the connecting waveguide 9, the output waveguide 3 and the filter 20 all adopt planar optical waveguides.

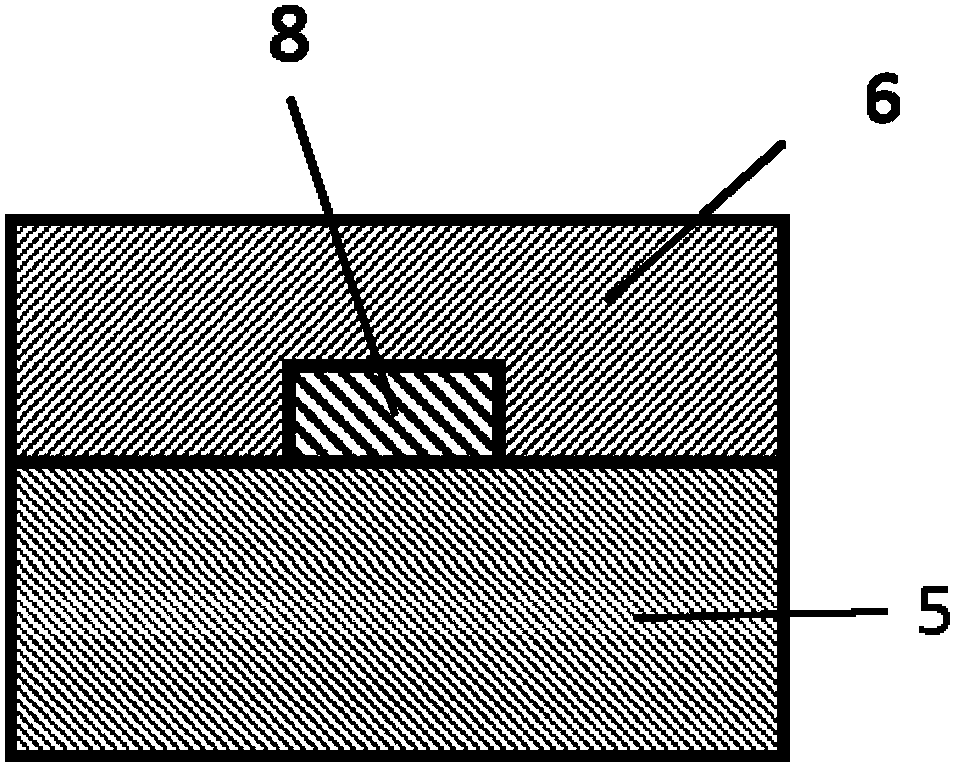

[0044] The waveguide upper...

Embodiment 2

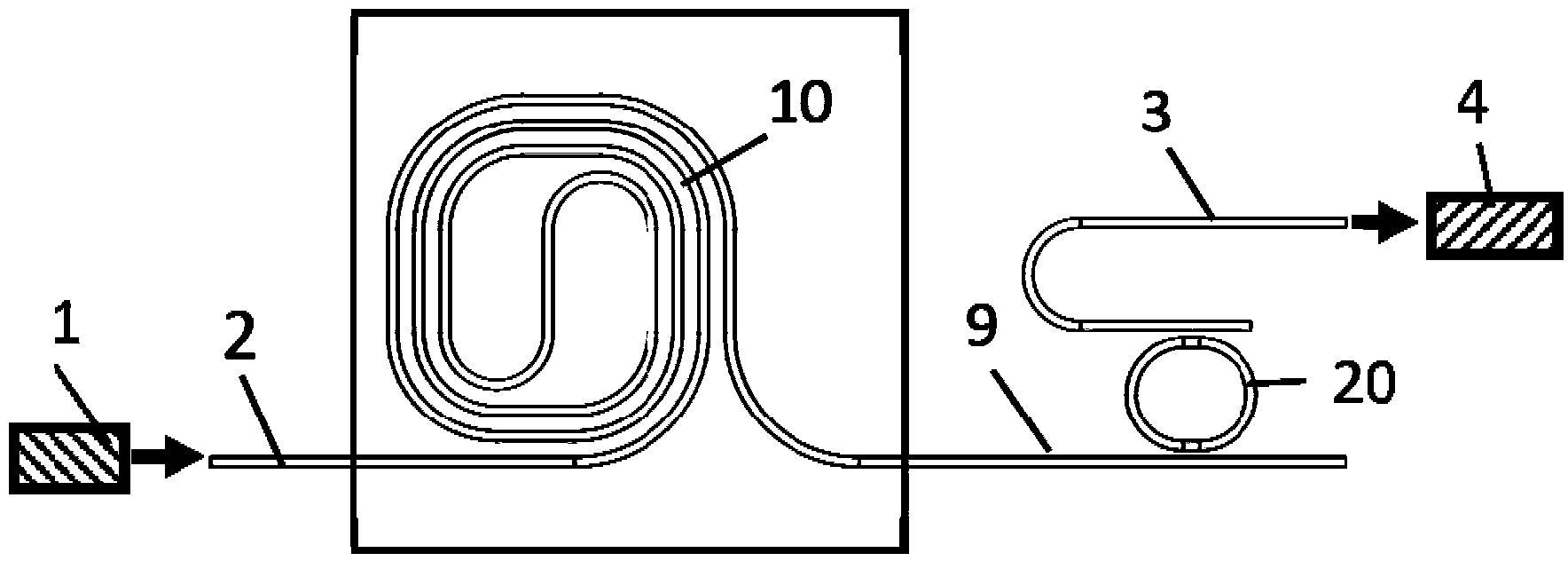

[0048] Such as figure 2 Shown, the present invention input waveguide 2, spiral sensing waveguide 10, connection waveguide 9, filter 20 and output waveguide 3, above-mentioned input waveguide 2, spiral sensing waveguide 10, filter 20, connection waveguide 9 and output The waveguides 3 are all located on the same substrate, between the waveguide lower cladding layer 5 and the waveguide upper cladding layer 6 .

[0049] The filter 20 adopts a single microring resonant cavity structure, and the input waveguide 2, the spiral sensing waveguide 10, the connecting waveguide 9, the output waveguide 3 and the filter 20 all adopt planar optical waveguides.

[0050] The waveguide upper cladding 6 of the spiral sensing waveguide 10 is removed, so that the waveguide core layer 8 is in contact with the detection sample 7 to realize detection, and the input end of the spiral sensing waveguide 10 is connected to an external wavelength tunable laser through the input waveguide 2, The output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com