Waste acid treatment system and method

A treatment method and a treatment system technology, applied in the field of sewage acid treatment system, can solve the problems of bad shape of gypsum slag, high acidity of sewage acid treatment, difficulty in slag dehydration, etc., and achieve comprehensive utilization, good quality and optimized The effect of the smelting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

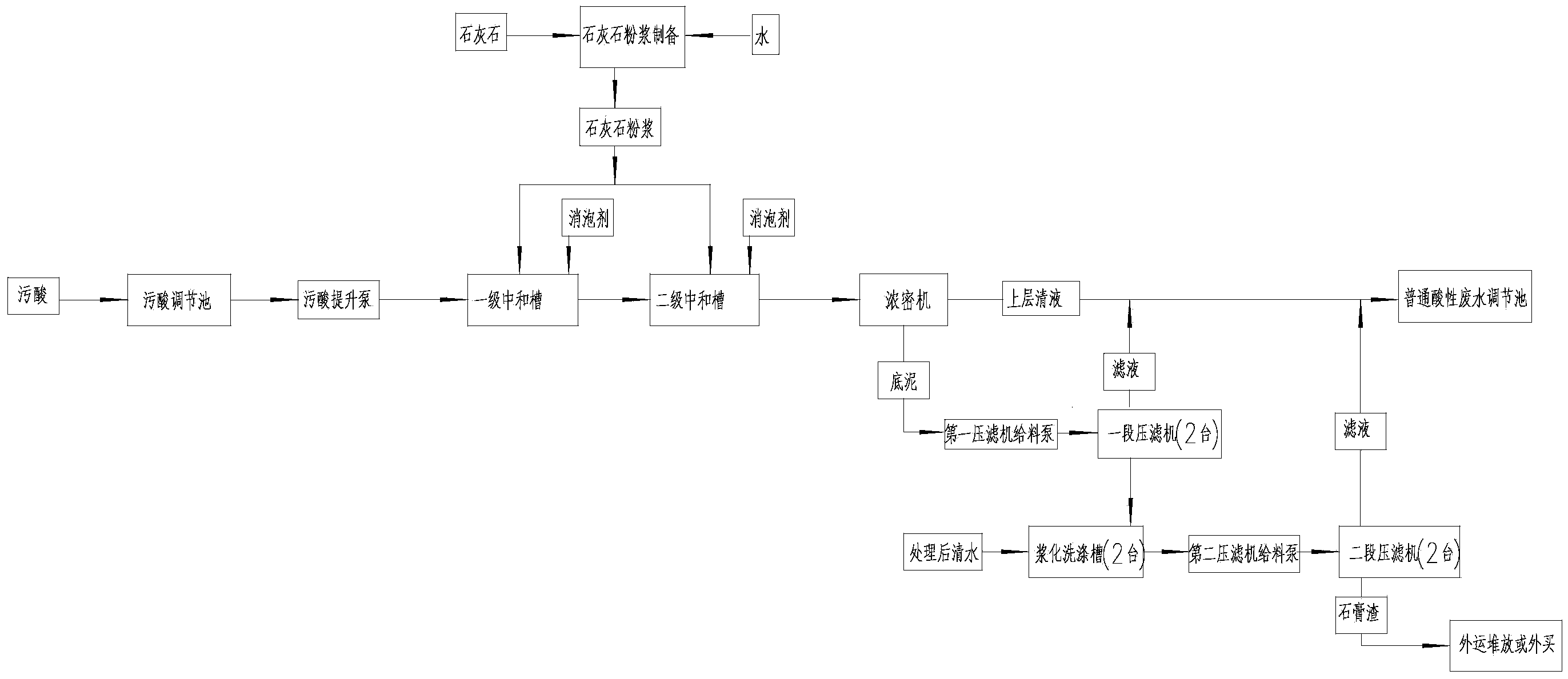

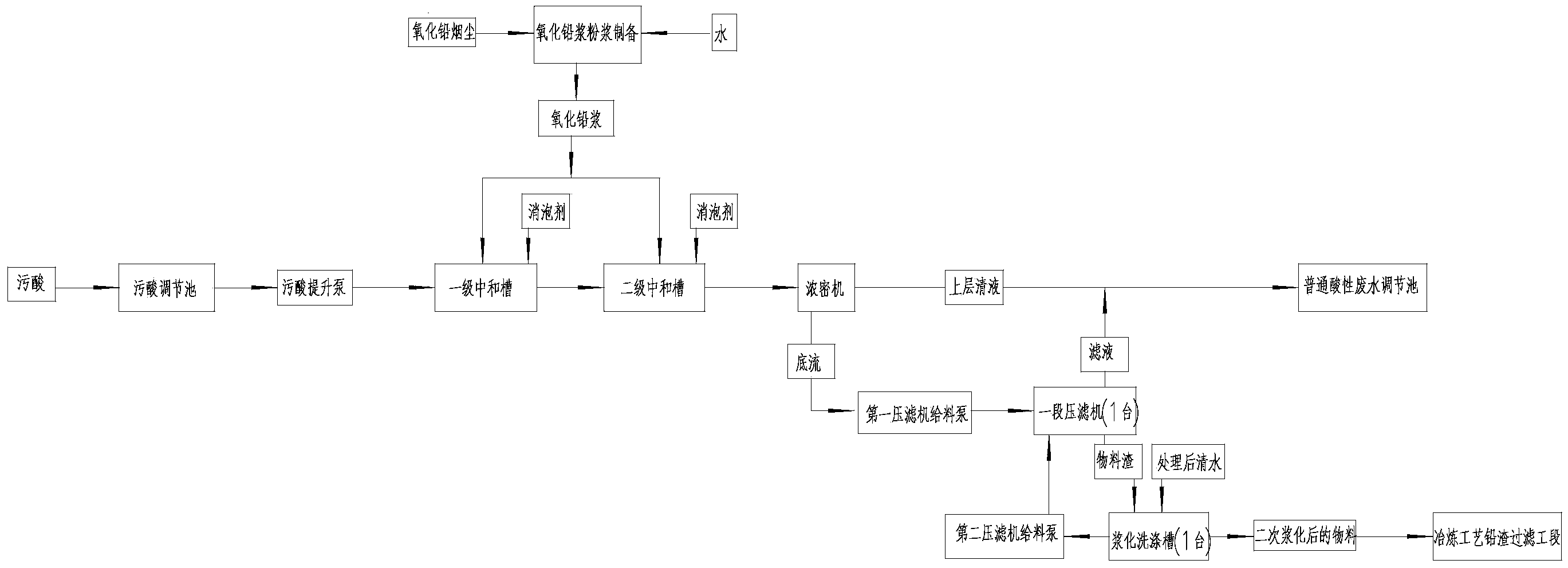

[0033] Such as figure 1 As shown, a sewage acid treatment system includes a sewage acid regulating tank connected in sequence, a sewage acid lift pump, a primary neutralization tank, a secondary neutralization tank, a thickener, a first filter press feed pump, a stage A filter press, a slurrying tank, a second filter press feed pump, and a second-stage filter press, the thickener, the first-stage filter press, and the second-stage filter press are respectively connected to an ordinary acid wastewater regulating tank.

[0034] The present embodiment is based on the dirty acid treatment method of the above-mentioned dirty acid treatment system, comprising the steps of:

[0035] Step (1): The sewage acid is lifted into the first-level neutralization tank by the lifting pump, and the dirty acid flows to the second-level neutralization tank by itself, and limestone slurry is added to both the first-level neutralization tank and the second-level neutralization tank to adjust the se...

Embodiment 2

[0039] Such as figure 1 As shown, a sewage acid treatment system includes a sewage acid regulating tank connected in sequence, a sewage acid lift pump, a primary neutralization tank, a secondary neutralization tank, a thickener, a first filter press feed pump, a stage A filter press, a slurrying tank, a second filter press feed pump, and a second-stage filter press, the thickener, the first-stage filter press, and the second-stage filter press are respectively connected to an ordinary acid wastewater regulating tank.

[0040] The present embodiment is based on the dirty acid treatment method of the above-mentioned dirty acid treatment system, comprising the steps of:

[0041] Step (1): The sewage acid is lifted into the first-level neutralization tank by the lifting pump, and the dirty acid flows to the second-level neutralization tank by itself, and limestone slurry is added to both the first-level neutralization tank and the second-level neutralization tank to adjust the se...

Embodiment 3

[0045] Such as figure 1 As shown, a sewage acid treatment system includes a sewage acid regulating tank connected in sequence, a sewage acid lift pump, a primary neutralization tank, a secondary neutralization tank, a thickener, a first filter press feed pump, a stage A filter press, a slurrying tank, a feed pump of the second filter press, and a second-stage filter press, the thickener, the first-stage filter press, and the second-stage filter press are respectively connected to an ordinary acid wastewater regulating tank.

[0046] The present embodiment is based on the dirty acid treatment method of the above-mentioned dirty acid treatment system, comprising the steps of:

[0047]Step (1): The sewage acid is lifted into the first-level neutralization tank by the lifting pump, and the dirty acid flows to the second-level neutralization tank by itself, and limestone slurry is added to both the first-level neutralization tank and the second-level neutralization tank to adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com