Pre-treatment method of semi-coke wastewater

A semi-coke wastewater and pretreatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of harsh reaction conditions, difficult removal of organic matter, high price, etc. Achieve the effects of reducing the concentration of organic pollutants, improving the ability to remove organic matter, and easy to control reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

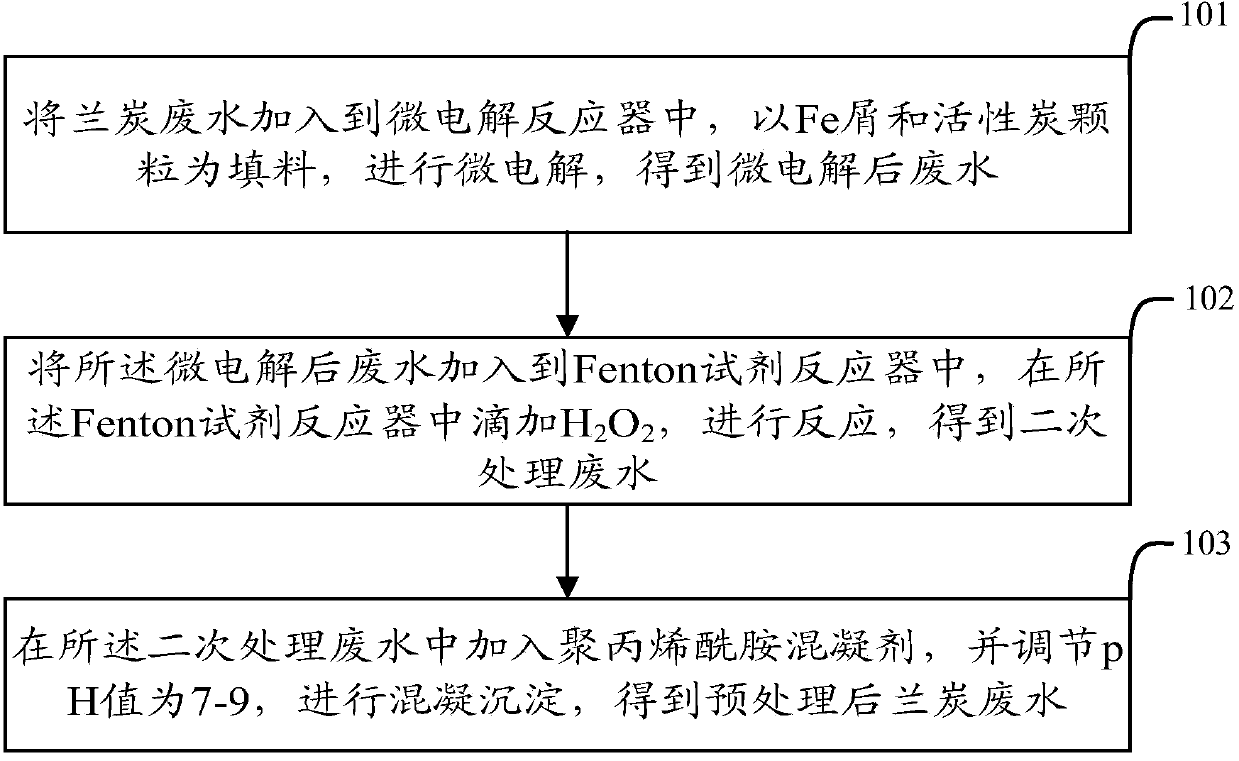

[0026] For the pretreatment method of blue charcoal wastewater provided by the embodiment of the present invention, please refer to figure 1 , Including the following steps:

[0027] Step 101: Add the blue charcoal wastewater to a micro-electrolysis reactor, and use Fe scraps and activated carbon particles as fillers to perform micro-electrolysis to obtain micro-electrolysis wastewater;

[0028] In step 101, in the micro-electrolysis reactor, by directly contacting Fe scraps and activated carbon together, soaking them in the conductive blue carbon wastewater solution, battery effect occurs to form countless tiny corrosive primary cells, and the metal anode is corroded At the same time, consumption and electrochemical corrosion trigger a series of synergistic effects, including flocculation, adsorption, bridging, roll sweeping, co-precipitation, electrodeposition, electrochemical reduction and other comprehensive effects, so as to achieve the degradation of organic pollutants. . In...

Embodiment 2

[0035] In this embodiment, the preparation method of the pretreatment method of blue charcoal wastewater includes the following steps:

[0036] S1: Add the blue charcoal wastewater to the micro-electrolysis reactor, and use Fe scraps and activated carbon particles as fillers to perform micro-electrolysis to obtain wastewater after micro-electrolysis;

[0037] In this step, the mass of the Fe chips and the activated carbon particles are equal, and the particle size of the Fe chips is 5-7 mm; the particle size of the activated carbon particles is 2-3 mm; the time of the micro-electrolysis It is 80-100 minutes; with the combination of the above process limitations, the micro-electrolysis effect is better.

[0038] S2: Add the wastewater after the micro-electrolysis into the Fenton reagent reactor, and add H dropwise to the Fenton reagent reactor 2 O 2 , The reaction is carried out to obtain secondary treated wastewater;

[0039] In S2, the wastewater after micro-electrolysis is added to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com