Preparation method of p-aminophenol

A technology for p-aminophenol and a reaction kettle, which is applied in the field of preparation of p-aminophenol, can solve the problems of complex components and complicated preparation processes, and achieves the effects of convenient and simple preparation, simple components and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

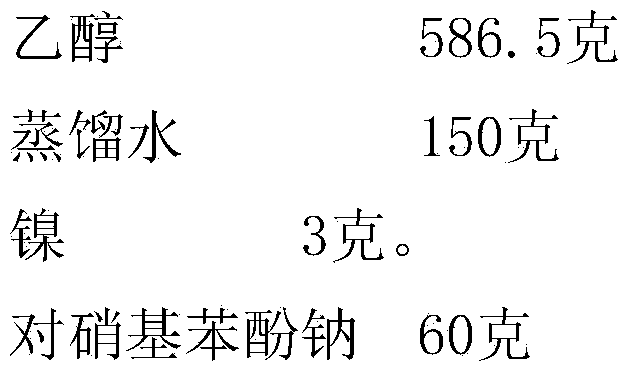

Embodiment 1

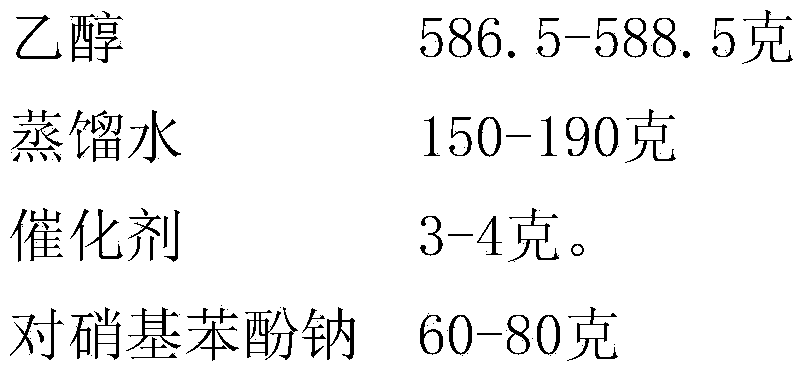

[0026] A p-aminophenol consisting of raw materials by weight of,

[0027]

[0028] A preparation method for p-aminophenol, comprising the following processing steps,

[0029] (1) Activation reaction

[0030] 1. Weigh 299.5 grams of ethanol and 60 grams of distilled water into the autoclave;

[0031] 2. Weigh 3 grams of nickel and put it into a high-pressure reactor;

[0032] 3. Replace the air in the reactor with 0.3MP nitrogen for 3 times, and then replace the nitrogen in the high-pressure reactor with 0.3MP hydrogen for 3 times;

[0033] 4. Pressurize the hydrogen in the reactor to 1.1MP, start stirring and heating, and stop heating when the temperature rises to 85°C. When the temperature reaches 100°C, turn on the cooling water and keep the temperature in the kettle at 100-101°C for 40 minutes.

[0034] 5. Start to lower the temperature, and discharge hydrogen when the temperature is 75°C.

[0035] (2) Hydrogenation reaction

[0036] 1. Weigh 60 grams of sodium p-n...

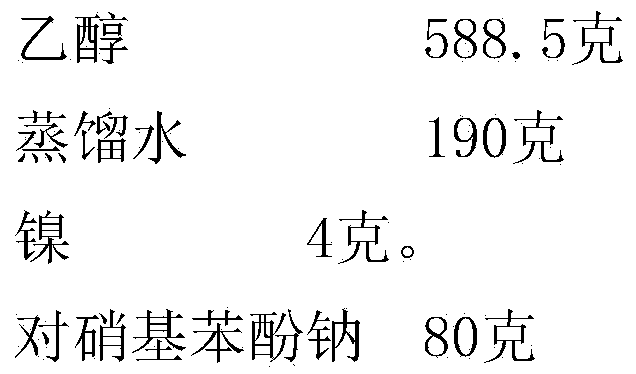

Embodiment 2

[0043] A p-aminophenol consisting of raw materials by weight of,

[0044]

[0045] A preparation method for p-aminophenol, comprising the following processing steps,

[0046] (1) Activation reaction

[0047] 1. Weigh 300.5 grams of ethanol and 80 grams of distilled water into the autoclave;

[0048] 2. Weigh 3-4 grams of nickel and put it into a high-pressure reactor;

[0049] 3. Replace the air in the autoclave with 0.3MP nitrogen for 3 times, and then replace the nitrogen in the autoclave with 0.3MP hydrogen for 3 times;

[0050] 4. Pressurize the hydrogen in the autoclave to 1.1MP, start stirring and heating, and stop heating when the temperature rises to 85°C. When the temperature reaches 100°C, turn on the cooling water and keep the temperature in the autoclave at 100-101°C for 40 minutes.

[0051] 5. Start to lower the temperature, and discharge hydrogen when the temperature is 75°C.

[0052] (2) Hydrogenation reaction

[0053] 1. Weigh 80 grams of sodium p-nitr...

Embodiment 3

[0060] A p-aminophenol consisting of raw materials by weight of,

[0061]

[0062] A preparation method for p-aminophenol, comprising the following processing steps,

[0063] (1) Activation reaction

[0064] 1. Weigh 300 grams of ethanol and 70 grams of distilled water into the autoclave;

[0065] 2. Weigh 3.5 grams of nickel and put it into the autoclave;

[0066] 3. Replace the air in the autoclave with 0.3MP nitrogen for 3 times, and then replace the nitrogen in the autoclave with 0.3MP hydrogen for 3 times;

[0067] 4. Pressurize the hydrogen in the autoclave to 1.1MP, start stirring and heating, and stop heating when the temperature rises to 85°C. When the temperature reaches 100°C, turn on the cooling water and keep the temperature in the autoclave at 100-101°C for 40 minutes.

[0068] 5. Start to cool down, and discharge hydrogen when the temperature is 75°C.

[0069] (2) Hydrogenation reaction

[0070] 1. Weigh 70 grams of sodium p-nitrophenolate, put it into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com