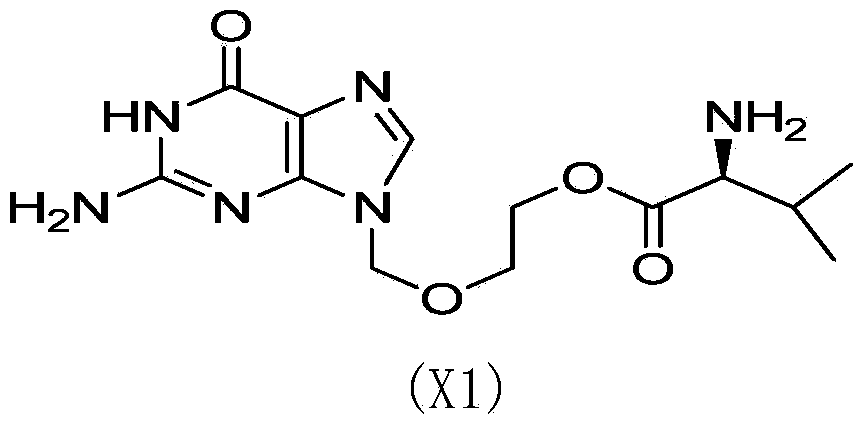

Preparation method of valine acyclovir

A valacyclovir and valine technology, applied in the field of chemistry, can solve problems such as few synthetic and purification methods, and achieve the effects of low pressure, low temperature and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

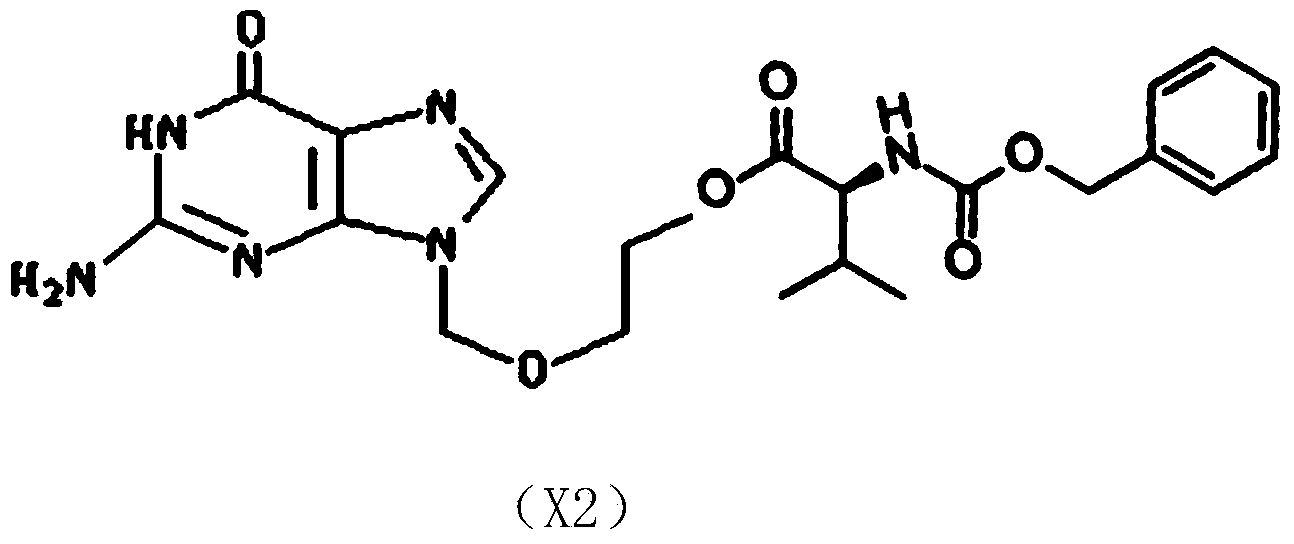

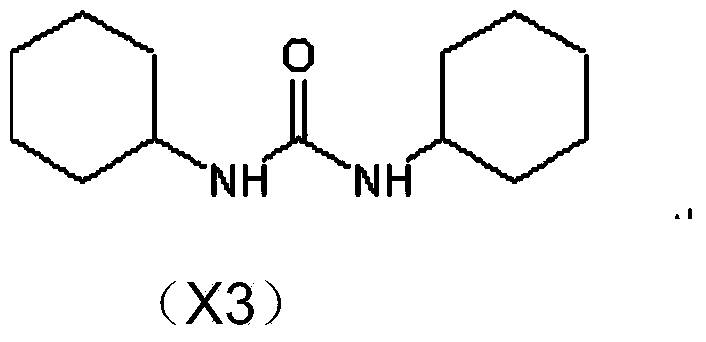

Embodiment 1

[0027] Add 30g of acyclovir, 300-450g of N,N-dimethylformamide, 30-100g of CBZ-L-valine, and 30g of N,N'-dicyclohexylcarboimide into a 1000mL three-necked bottle. -90g, 0.3-3g of 4-dimethylaminopyridine. Stir the reaction at 20-30°C for 10-15 hours.

[0028] Add 0.3-3 g of carbon powder to the reaction liquid, stir for 30 min at room temperature and suction filter to obtain X2 filtrate.

[0029] The obtained X2 filtrate was concentrated under reduced pressure, 300-600 g of methanol solution was added to the concentrate, refluxed to dissolve until it was dissolved, and then crystallized by gradient cooling, stirred at 50-55°C for 1 hour, and the stirring speed was 300-400r / min. Naturally lower the temperature to 30°C, cool down to 0°C in 1-2 hours, and stir at a speed of 50-100r / min. 30-60 g of methanol was washed by suction filtration at 0°C. The product X2 was dried at 80°C and weighed 57.2g. The product yield is 93.4%, and the purity of liquid chromatography is ≧99.5%

...

Embodiment 2

[0033] On the basis of Example 1, the organic solvent is a mixed solvent of methanol and ethanol, the volume ratio of methanol and ethanol is 8:2-9.5:0.5, the single yield is greater than 92.8%, and the purity is >99%.

Embodiment 3

[0035] 1. Add acyclovir 30g, N,N-dimethylformamide 300-450g, CBZ-L-valine 30-100g, N,N'-dicyclohexylcarbonyl Amine 30-90g, 4-dimethylaminopyridine 0.3-3g. Stir the reaction at 20-30°C for 10-15 hours.

[0036] 2. Add 0.3-3 g of carbon powder to the reaction solution, stir for 30 minutes at room temperature and suction filter to obtain X2 filtrate.

[0037] 3. Concentrate the obtained X2 filtrate under reduced pressure, add 300-600g of methanol solution to the concentrated solution, reflux to dissolve until clear, then crystallize by gradient cooling, stir at 50-55°C for 1 hour, and the stirring speed is 300-400r / min. Naturally lower the temperature to 30°C, cool down to 0°C in 1-2 hours, and stir at a speed of 50-100r / min. 30-60 g of methanol was washed by suction filtration at 0°C. The product X2 was dried at 80°C and weighed 56.7g. The product yield is 92.6%, and the liquid chromatography purity is ≧99.7%.

[0038] 4. Put 56.7g and 500-800g of methanol, 0.5-5g of 10% pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com