Preparation method of polyvinyl butyral

A polyvinyl butyral and polyvinyl alcohol technology, which is applied in the field of preparation of polyvinyl butyral (PVB), can solve the problems of cross-linking reaction products, uneven distribution of acetal groups, affecting product quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

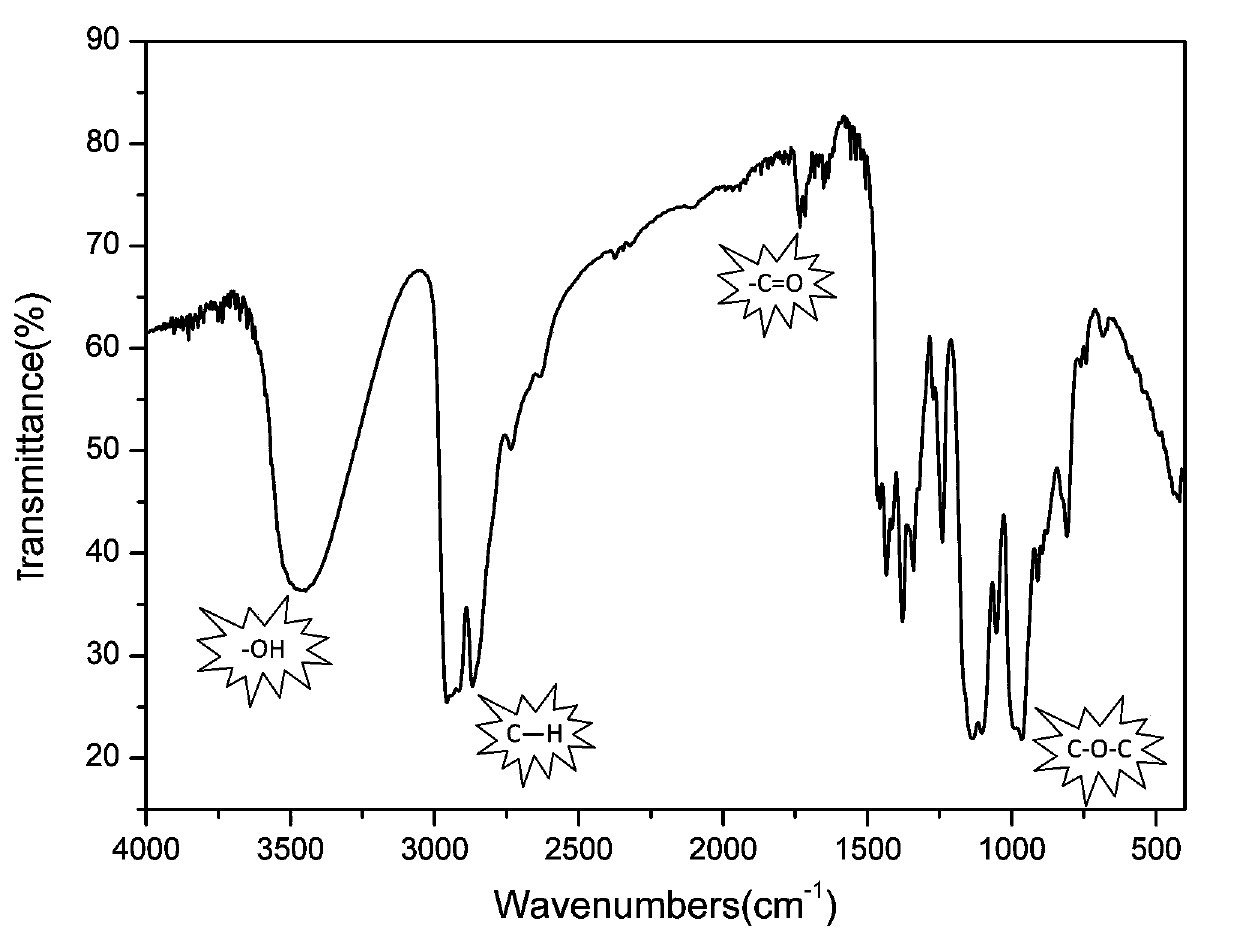

Image

Examples

Embodiment 1

[0021] Add 100 parts of PVA (unless otherwise specified, the parts used for each material are parts by weight) and 900 parts of deionized water into a three-necked flask equipped with a stirrer, reflux condenser and thermostat, raise the temperature to 92°C and stir until All the PVA was dissolved, and after cooling to 62°C, 60 parts of butyraldehyde was added and stirred thoroughly to obtain a uniformly mixed PVA-butyraldehyde mixed solution. Add a small amount of dilute hydrochloric acid with a pH value of 1 to a four-necked flask equipped with a stirrer, reflux condenser and constant temperature instrument, keep the temperature at 25°C, and then use a constant pressure dropping funnel to the four-necked flask at a substantially uniform speed at the same time Slowly add a mixed solution of dilute hydrochloric acid and PVA-butyraldehyde with a concentration of 15% dropwise, so that the two mixed liquids are added dropwise at the same time within about 1 hour, and continue to r...

Embodiment 2

[0024] Add 100 parts of PVA and 800 parts of deionized water into a three-necked flask equipped with a stirrer, reflux condenser and a thermostat, raise the temperature to 94°C and stir until the PVA is completely dissolved. After cooling to 64°C, add 62 parts of butyraldehyde through Thoroughly stir to obtain a uniformly mixed PVA-butyraldehyde mixed solution. Add a small amount of dilute hydrochloric acid with a pH value of 2 to a four-necked flask equipped with a stirrer, a reflux condenser and a constant temperature instrument, keep the temperature at 27°C, and then use a constant pressure dropping funnel to the four-necked flask at a substantially uniform speed at the same time Slowly add a mixed solution of dilute hydrochloric acid and PVA-butyraldehyde with a concentration of 12% dropwise, so that the two mixed liquids are added dropwise at the same time within about 1 hour, and continue to react under stirring until the degree of acetalization basically does not change ...

Embodiment 3

[0026] Add 100 parts of PVA and 1000 parts of deionized water into a three-necked flask equipped with a stirrer, reflux condenser and thermostat, raise the temperature to 92°C and stir until the PVA is completely dissolved. After cooling to 62°C, add 63 parts of butyraldehyde through Thoroughly stir to obtain a uniformly mixed PVA-butyraldehyde mixed solution. Add a small amount of dilute hydrochloric acid with a pH value of 0.72 to a four-necked flask equipped with a stirrer, reflux condenser and constant temperature instrument, keep the temperature at 20°C, and then use a constant pressure dropping funnel to the four-necked flask at a substantially uniform speed at the same time Slowly add a mixed solution of dilute hydrochloric acid and PVA-butyraldehyde with a concentration of 7% dropwise, so that the two mixed liquids are added dropwise at the same time within about 1 hour, and continue to react under stirring until the degree of acetalization basically does not change (a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com