Edible ink for screen printing and preparation method thereof

A food and ink technology, applied in the field of printing ink, can solve the problems of high price, immature research technology, unsuitable for mass printing, etc., and achieve the effect of simple method, low price and good commercial application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

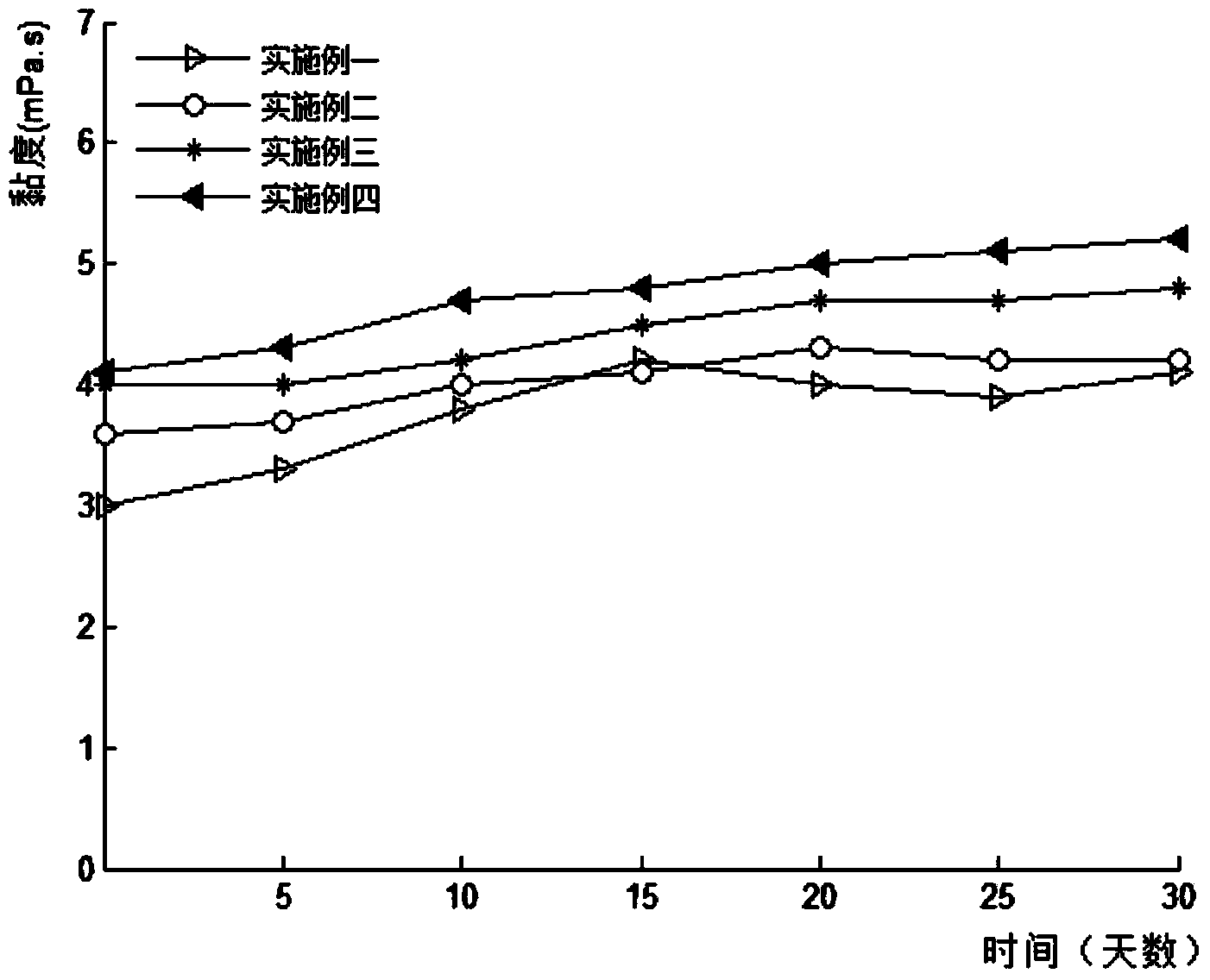

Examples

Embodiment 1

[0033] Embodiment 1: the preparation method of edible red ink is as follows:

[0034] (a) Protoplasm preparation method: earlier with 60% (weight) fructose, 15% (weight) 1,2 propylene glycol; 1% (weight) beeswax, 2% (weight) sodium alginate, 5% (weight) arabic acid Pour the gum and 10% (weight) deionized water into the container and stir evenly, then pour it into a high-speed magnetic heating stirrer, adjust the temperature to 45°C, stir for about 15 minutes, then place it for 15 minutes, and cool to normal temperature .

[0035] (b) Add 5% (weight) edible monascus red pigment into the original slurry and stir for about 30 minutes, then add 2% (weight) shellac edible solution and stir for another 10 minutes. An edible ink for screen printing with an ink particle diameter less than 80 μm is obtained by using an ink filter.

Embodiment 2

[0036] Embodiment 2: the preparation method of edible gardenia yellow pigment ink is as follows:

[0037] (a) Protoplasm preparation method: earlier 25% (weight) oligofructose, 25% (weight) isomaltulose, 10% (weight) 1,2 propanediol 10% (weight) n-propanol, 1% (weight) ) stearic acid, 1% (weight) palmitic acid, 2% (weight) sodium alginate, 1% (weight) bean gum, 1% (weight) guar gum, 1% (weight) gum arabic, and 16 % (weight) deionized water is poured into a container and stirred evenly, then poured into a high-speed magnetic heating stirrer, the temperature is adjusted to 50°C, stirred for about 20 minutes, left for another 20 minutes, and cooled to normal temperature.

[0038] (b) Add 4% (weight) edible gardenia yellow pigment into the protoste and stir evenly for about 30 minutes, then add 3% shellac alcohol solution and stir for another 10 minutes. An edible ink for screen printing with an ink particle diameter less than 80 μm is obtained by using an ink filter.

Embodiment 3

[0039] Embodiment 3: the preparation method of edible capsanthin ink is as follows:

[0040] Protoplasm preparation method: earlier 50% (weight) starch sugar, 15% (weight) n-propanol, 1% (weight) polyhydric alcohol, 2% (weight) sodium alginate, and 14% deionized water are poured into container After stirring evenly in the medium, pour it into a high-speed magnetic heating stirrer, adjust the temperature to 45°C, stir for about 15 minutes, and let it stand for another 15 minutes, and cool to normal temperature.

[0041] (b) 8% (weight) edible capsanthin was added in the protoste and stirred evenly for about 30 minutes, then 8% (weight) shellac alcohol solution was added and stirred for another 10 minutes. An edible ink for screen printing with an ink particle diameter less than 80 μm is obtained by using an ink filter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com