Aspergillus tubingensis for high-yield production of glucoamylase, alpha-amylase and acidic protease and application thereof

A technology of acid protease and Aspergillus tubingensis, applied in biochemical equipment and methods, preparation of alcoholic beverages, methods based on microorganisms, etc., can solve the problems of single strain enzyme system and poor wine quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

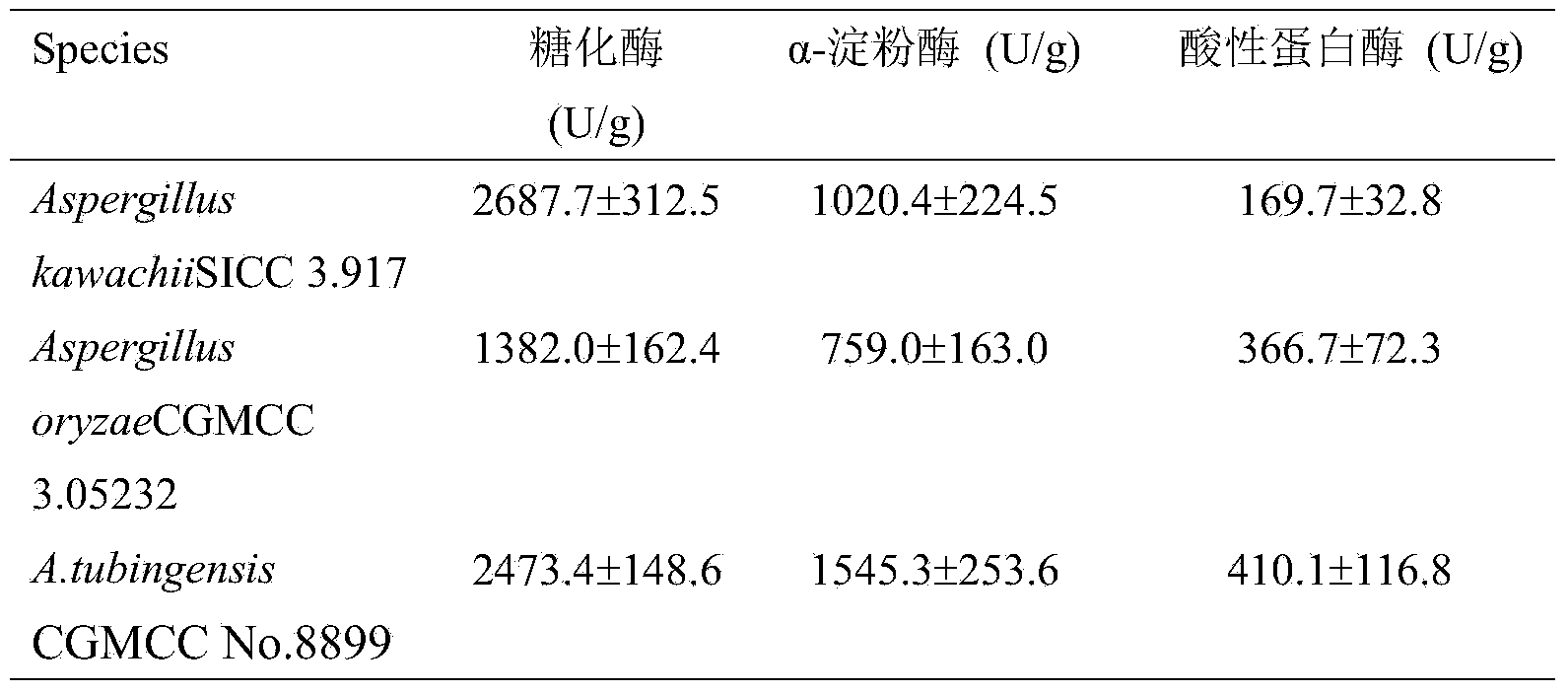

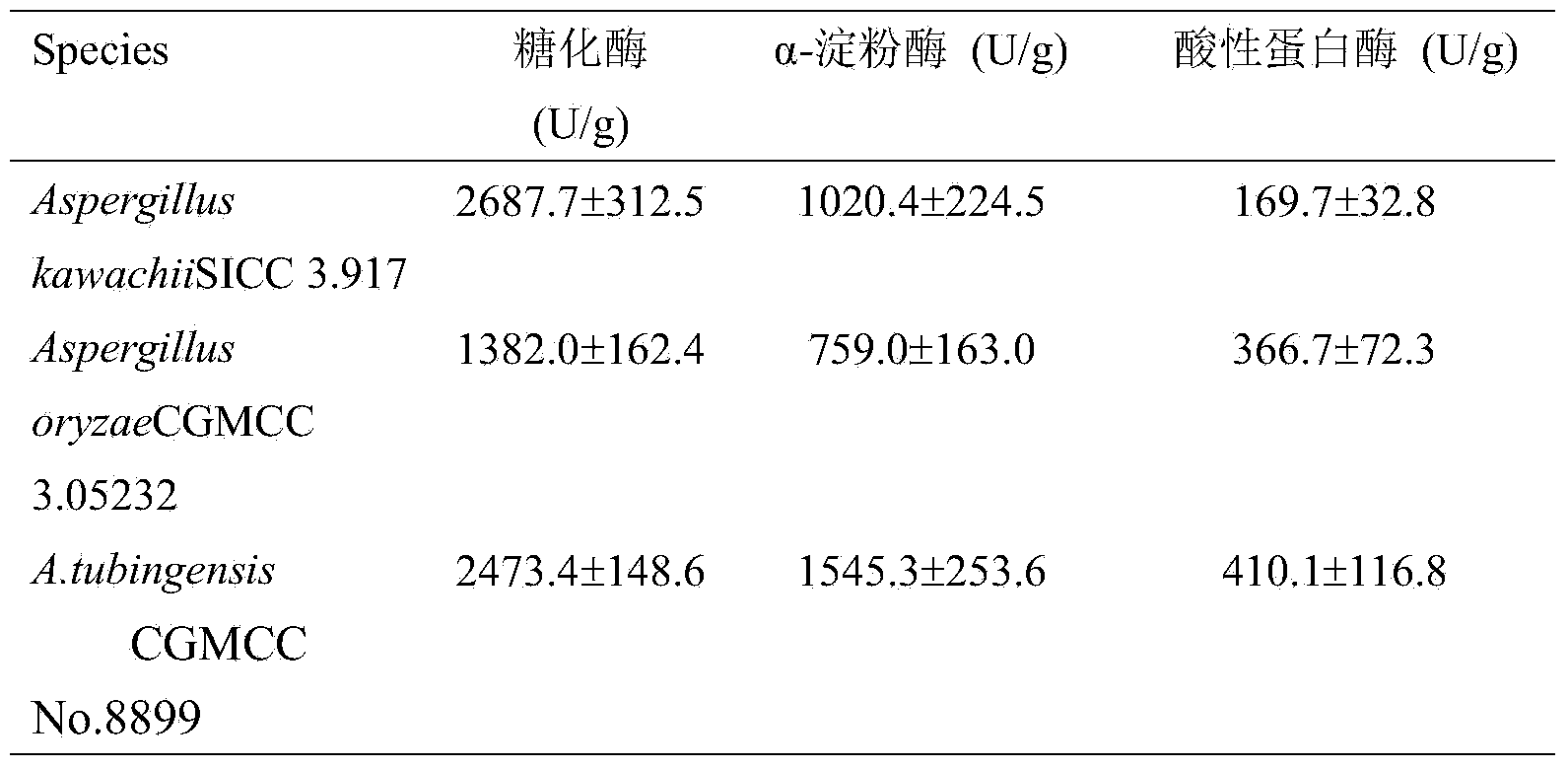

[0026] Example 1: Comparative study on production of glucoamylase, α-amylase and acid protease by solid-state fermentation of Aspergillus tubingensis and certain commercial saccharification molds SC1 and ZKY1

[0027] The Aspergillus tubingensis was inoculated in the bran solid-state fermentation medium, fermented at a constant temperature of 30°C for 72h, and the enzyme activity of the solid-state fermentation bacteria preparation was determined. The specific method is as follows:

[0028] 1. Sample preparation: Weigh 5.0g of solid fermentation medium (dry weight), put it into a 250ml beaker, add 90ml of water and 10ml of pH4.6 acetic acid-sodium acetate buffer, shake well, and keep it in a water bath at 40°C for 1h. Stir every 15 minutes. Filter with absorbent cotton, and the filtrate is 5% solid koji extract.

[0029] 2. Determination of glucoamylase, α-amylase and acid protease: refer to Shen Yifang's "Compendium of Liquor Production Technology" and QBT4257-2011 General A...

example 2

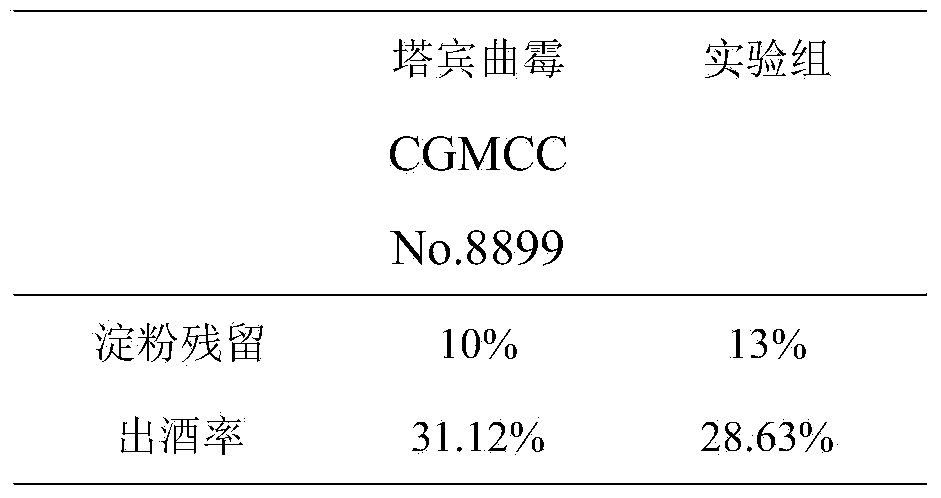

[0033] Example 2: Improving the utilization rate of raw material starch and liquor yield of liquor, and maintaining the flavor of liquor

[0034] Aspergillus tabin (CGMCC No.8899) was cultured on a PDA slope, and the spores were collected and then subjected to three-stage expansion culture (triangular flask, shallow plate koji making and koji making koji). The amount used is added to the fermented grains that have been mixed with Daqu, and then continue to ferment according to the traditional process.

[0035] The results of the analysis are shown in Table 2. Compared with the control group using only Daqu, the starch utilization rate and liquor production rate in the experimental group added with Aspergillus tabinensis (CGMCC No.8899) were significantly improved: the starch residues were respectively reduced by 3% in liquor The alcohol yield was 3.5%. The aroma and taste of the liquor produced by the two groups were evaluated and scored. The experimental group retained bette...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com