Method for preparing praseodymium-doped titanium nitride coating on surface of medical titanium alloy

A technology of titanium nitride coating and titanium alloy, which is applied in metal material coating technology, coating, medical science, etc., can solve the problems of insufficient biological performance, blood corrosion resistance on the surface of medical titanium alloy, and improve biological performance. Improvement of performance and anti-corrosion performance, effect of reduction of hemolysis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

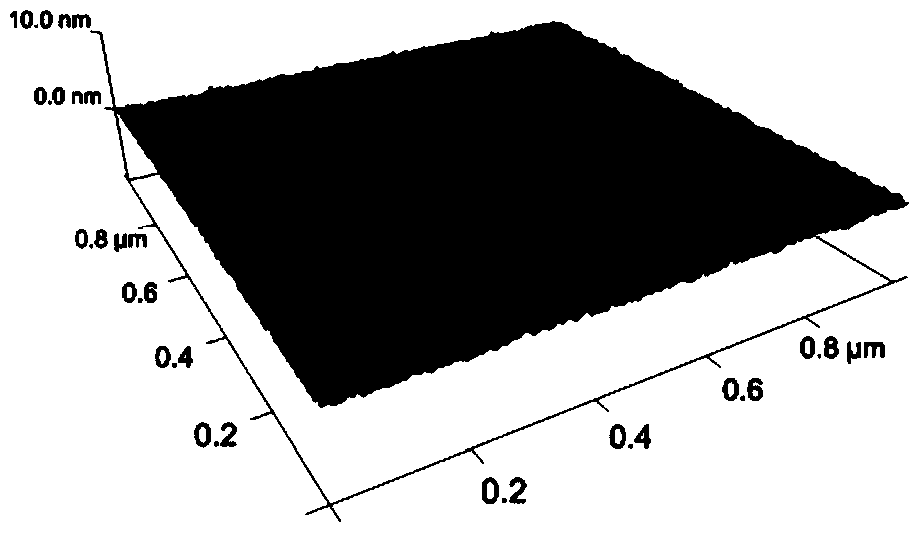

[0024] see Figure 1 to Figure 4 , the present invention prepares a method for preparing a praseodymium-doped titanium nitride coating on the surface of a medical titanium alloy, comprising the following steps:

[0025] 1) Cut a medical titanium alloy rod with a diameter of 25mm into a disc sample of φ25mm×2mm as a substrate, after degreasing and polishing the surface, immerse in acetone for ultrasonic cleaning, and finally dehydrate with alcohol.

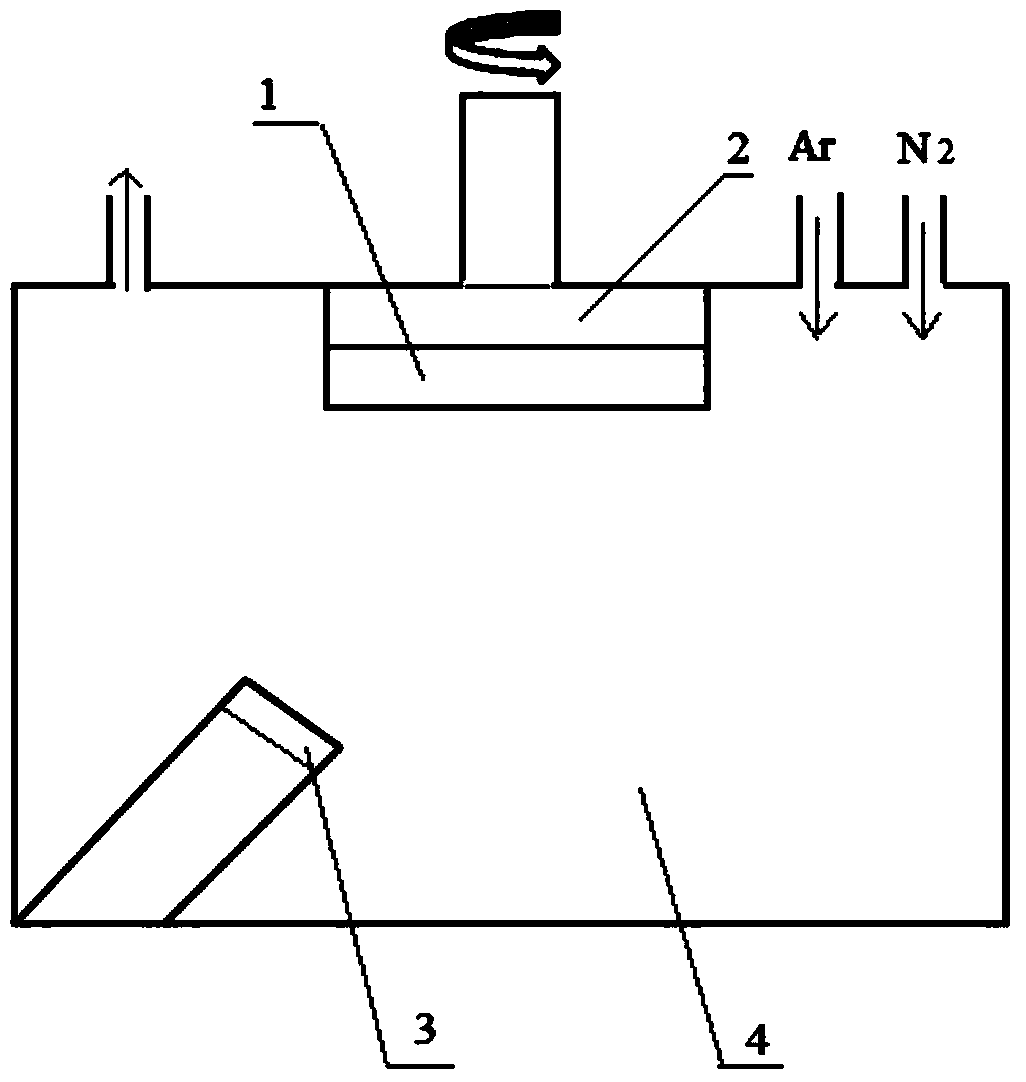

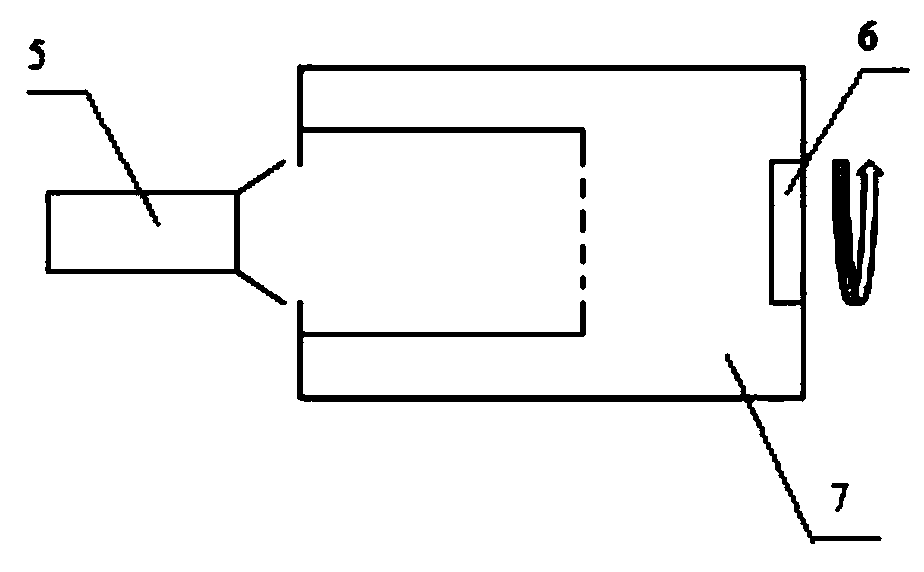

[0026] 2) Put the pretreated medical titanium alloy as the base material into the magnetron sputtering ion coating equipment. Such as figure 1 As shown, the magnetron sputtering coating equipment at least includes a vacuum chamber B4, a sample disk B1, a Ti target 3, and a heater 2. The distance can be adjusted, the Ti target 3 and the sample plate B1 are equipped with a mechanical transmission ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com