Graphite bearing plate for processing LED epitaxial wafer

A technology for carrying discs and wafers, used in crystal growth, single crystal growth, from chemically reactive gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

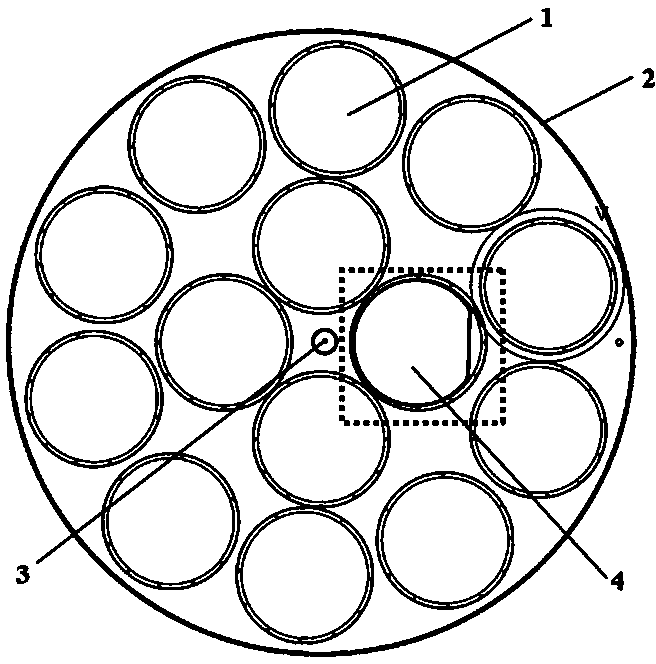

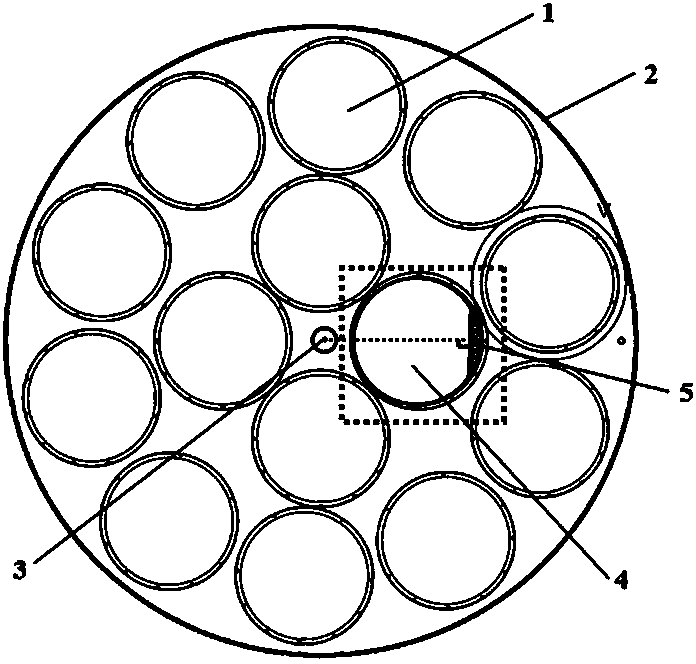

[0038] refer to Figure 3~Figure 6 As shown, a graphite carrier plate for LED epitaxial wafer manufacturing process, including: 14 4-inch (about 100.7mm in diameter) wafer grooves 1, the edge 2 of the graphite carrier plate and the shaft hole set in the center of the graphite carrier plate 3, wherein the wafer groove 1 is arranged above the carrier plate for placing a wafer substrate 4 with a flat edge (for convenience of illustration, only a wafer substrate in a wafer groove is shown in the figure), and A baffle structure 5 is provided on the inner edge 6 of the wafer groove, and the baffle is in a complementary relationship with the wafer substrate, and the two form a circle with the flat sides of the baffle and the wafer substrate as coincident sides.

[0039] In order to form a complementary relationship with the wafer substrate with flat sides, the shape of the baffle can be crescent-shaped or fan-shaped. In this embodiment, the crescent shape is preferred, and the circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com