Preparation method of anti-bacterial flame-retardant polyurethane synthetic leather applicable to furniture

A manufacturing method and synthetic leather technology, applied in the field of synthetic leather, can solve the problems of synthetic leather's unsatisfactory flame retardancy and antibacterial and antimildew properties, poor flame retardancy and antibacterial and antimildew effects, and achieve long-term antibacterial and antimildew properties Good, good flame retardant effect, good hand feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

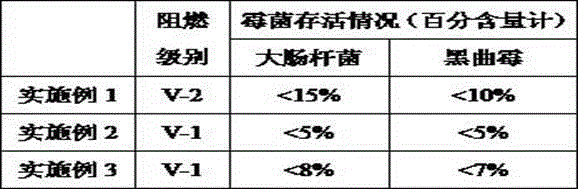

Examples

Embodiment 1

[0025] The manufacture method of the antibacterial flame-retardant polyurethane synthetic leather for furniture of the present embodiment comprises the following steps successively:

[0026] (1) Impregnate the base arrangement in polyurethane polyurea resin; then put the impregnated base cloth into water to solidify the polyurethane polyurea resin and extract the solvent dimethyl formamide in it, forming a porous layer on the surface of the base cloth Sexual elastic body;

[0027] The polyurethane polyurea resin is made of the following raw materials in weight ratio: 1000 parts of polytetrahydrofuran ether diol with an average molecular weight of 1000, 100 parts of 2,4-toluene diisocyanate, diphenylmethane-4,4- 190 parts of diisocyanate, 15 parts of chain extender (the chain extender is a combination of N-methyl-bisamine-propylamine and hydrazine hydrate with a molar ratio of 40:60), 4000 parts of dimethylformamide.

[0028] The preparation method of the above-mentioned polyu...

Embodiment 2

[0039] The manufacture method of the antibacterial flame-retardant polyurethane synthetic leather for furniture of the present embodiment comprises the following steps successively:

[0040] (1) Impregnate the base arrangement in polyurethane polyurea resin; then put the impregnated base cloth into water to solidify the polyurethane polyurea resin and extract the solvent dimethyl formamide in it, forming a porous layer on the surface of the base cloth Sexual elastic body;

[0041] The polyurethane polyurea resin is made of the following raw materials in weight ratio: 500 parts of polytetrahydrofuran ether diol with an average molecular weight of 2000, 120 parts of 2,4-toluene diisocyanate, diphenylmethane-4,4- 150 parts of diisocyanate, 10 parts of chain extender (the chain extender is a combination of N-methyl-bisamine-propylamine and hydrazine hydrate with a molar ratio of 40:60), 3000 parts of dimethylformamide;

[0042] The preparation method of the above-mentioned polyur...

Embodiment 3

[0053] The manufacture method of the antibacterial flame-retardant polyurethane synthetic leather for furniture of the present embodiment comprises the following steps successively:

[0054] (1) Impregnate the base arrangement in polyurethane polyurea resin; then put the impregnated base cloth into water to solidify the polyurethane polyurea resin and extract the solvent dimethyl formamide in it, forming a porous layer on the surface of the base cloth Sexual elastic body;

[0055] The polyurethane polyurea resin is made of the following raw materials in weight ratio: 1500 parts of polytetrahydrofuran ether diol with an average molecular weight of 4000, 80 parts of 2,4-toluene diisocyanate, diphenylmethane-4,4- 250 parts of diisocyanate, 25 parts of chain extender (the chain extender is a combination of N-methyl-diamine-propylamine and hydrazine hydrate with a molar ratio of 40:60), 6000 parts of dimethylformamide;

[0056] The preparation method of the above-mentioned polyure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com