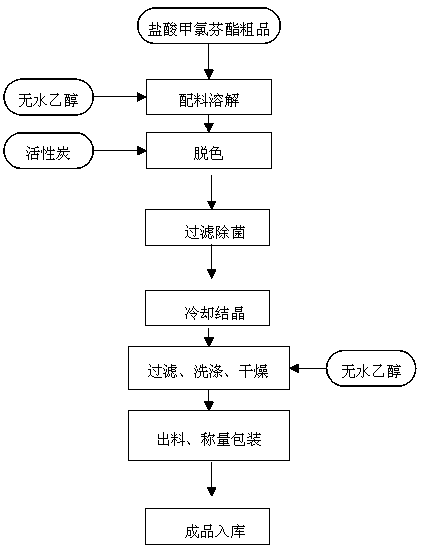

Purification process of meclofenoxate hydrochloride

A meclofenoxate hydrochloride and process technology, which is applied in the field of drug synthesis, can solve the problems of rare reports on the refining process, and achieve the effect of process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment: the refinement of aseptic meclofenoxate hydrochloride (in batch 40kg).

[0030] (10) Before the start of production, check that there are no products, documents or materials unrelated to the production of this batch of products left over from the previous batch in the equipment and workplace, and the equipment is in a clean and ready-to-use state. The operator checks and confirms that the salt tank and delivery pump are in good condition; confirms that the pipelines, valves, decarbonization filters, plate and frame filters, precision filters, and sterilization filters are in good condition; checks and confirms that measuring instruments, monitoring instruments, auxiliary The appliance is in good condition;

[0031] (20) Operators clean and disinfect the reaction delivery system according to the operating procedures (SOP-EC-009);

[0032] (30) Weighing, the operator approves the batch production order and the remaining materials of the previous batch, and ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com