New method for preparing solid lignin quaternary ammonium salt and application of solid lignin quaternary ammonium salt

A quaternary ammonium salt and lignin technology, applied in the field of lignin, can solve the problems of large amount of solvent used, many reaction steps, and reduced water solubility, etc., and achieve the effect of short reaction route, mild reaction conditions, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

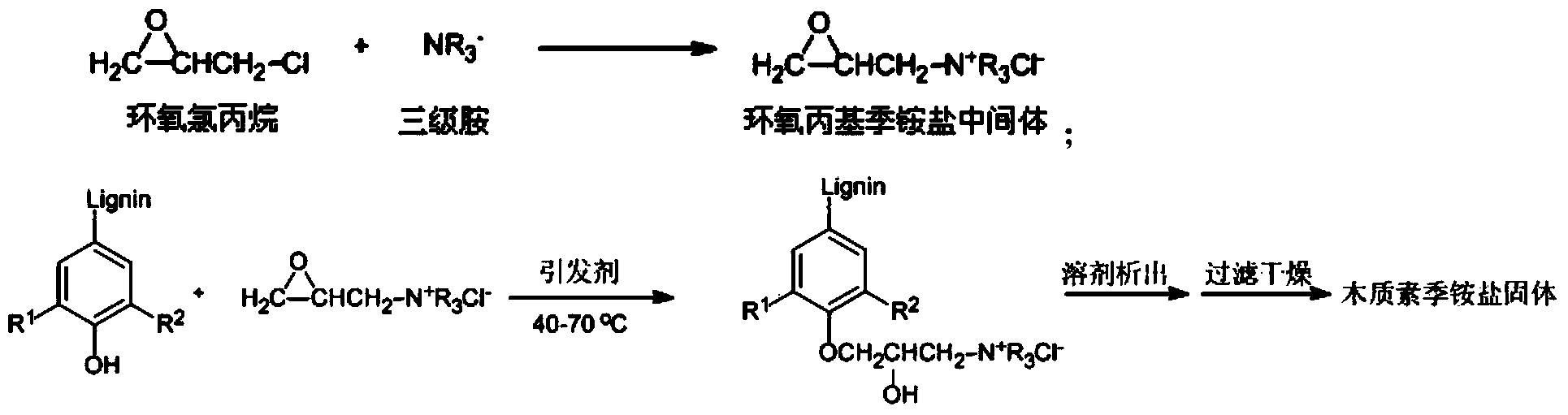

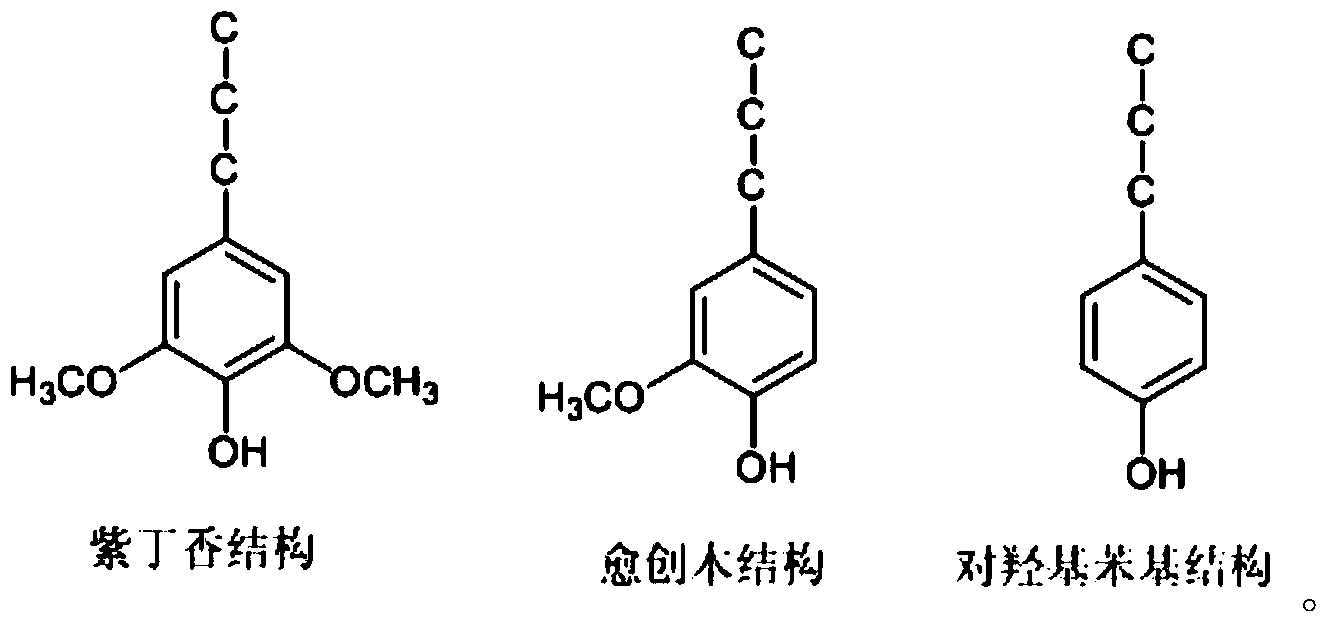

Method used

Image

Examples

Embodiment 1

[0050] 1) Weigh 4.6g of 33% trimethylamine aqueous solution into a single-necked flask, stir for 15min under an ice-salt bath at -5°C, then weigh 2.0g of epichlorohydrin, and gradually add it dropwise to trimethylamine aqueous solution . After the dropwise addition, continue to stir for 30 min, then place in a water bath at 40° C., stir and react for 2 h to obtain a pale yellow glycidyl quaternary ammonium salt intermediate. The molar ratio of trimethylamine and epichlorohydrin is 1.24:1.

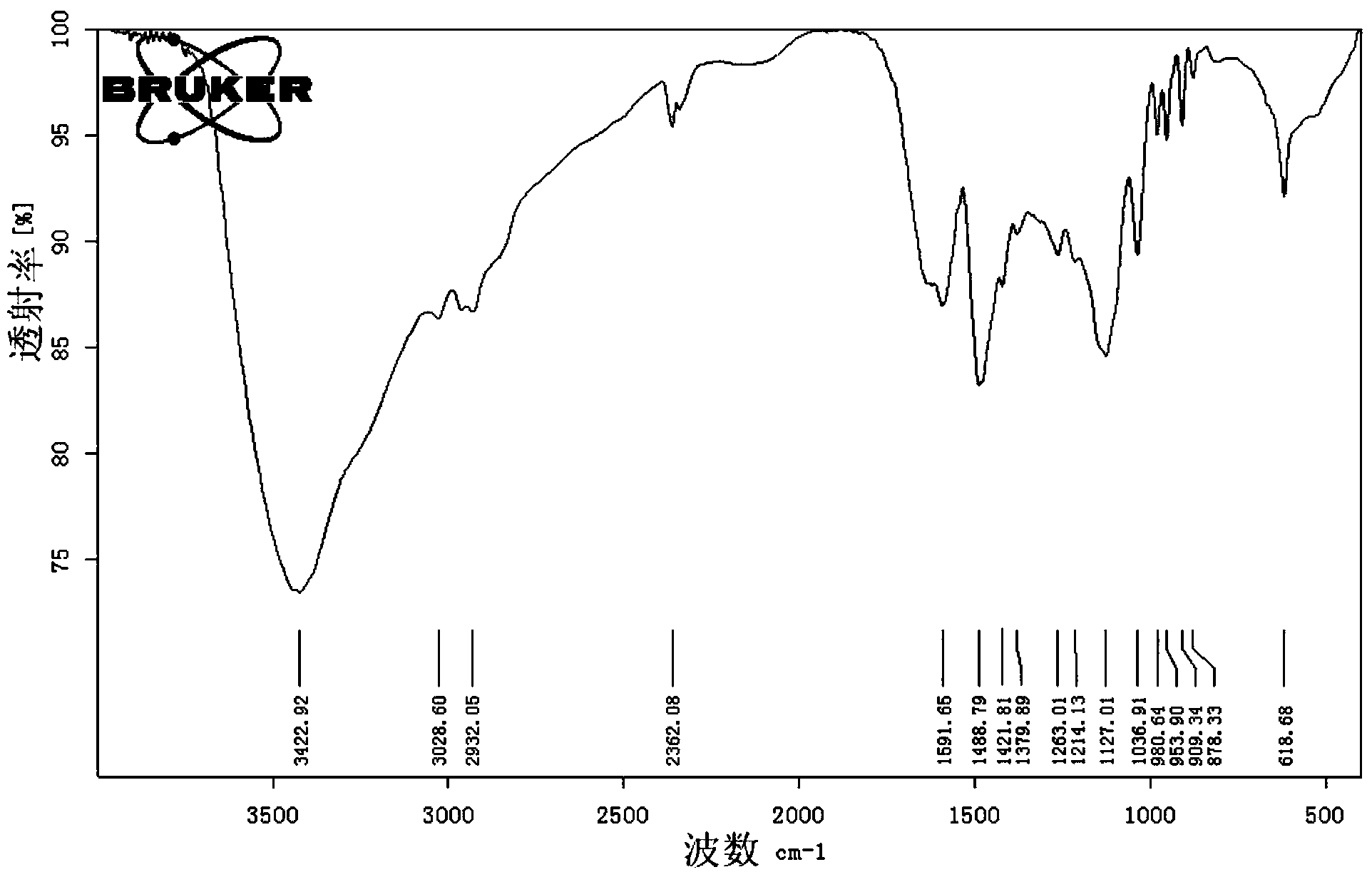

[0051] 2) Weigh 2.5g of alkali lignin into a three-necked flask, add 8mL of distilled water, add 0.05g of ammonium persulfate after heating up to 50°C, stir for a while, then add the prepared epoxypropyl quaternary ammonium salt intermediate, and stir to react After 3.5h, a black lignin quaternary ammonium salt solution was obtained. Wherein the molar ratio of the quaternary ammonium salt intermediate to the alkali lignin is 1.45:1, and the amount of the catalyst is 2.0% of the mass of th...

Embodiment 2

[0061] Weigh 0.7 g of triethylamine liquid into a single-necked flask, stir for 10 min in an ice-salt bath at 0° C., then weigh 1.0 g of epichlorohydrin, and gradually add it dropwise into triethylamine. Continue to stir for 30 min after the dropwise addition, and then place it at room temperature, stir and react for 3 h to obtain a pale yellow glycidyl quaternary ammonium salt intermediate. The molar ratio of triethylamine and epichlorohydrin is 1.11:1.

[0062] Weigh 1.2g of alkali lignin into a three-necked flask, add 5mL of distilled water, add 0.02g of potassium persulfate after heating up to 60°C, stir for a while, then add the prepared epoxypropyl quaternary ammonium salt intermediate, and stir for 3 hours , to obtain black lignin quaternary ammonium salt solution. The molar ratio of the quaternary ammonium salt intermediate to the alkali lignin is 1.74:1, and the amount of the catalyst is 1.6% of the mass of the alkali lignin.

[0063] The prepared lignin quaternary ...

Embodiment 3

[0066] Weigh 8.1 g of 33% trimethylamine aqueous solution into a single-necked flask, stir for 15 min under an ice-salt bath at -10°C, then weigh 3.0 g of epichlorohydrin, and gradually add it dropwise to the trimethylamine aqueous solution. Continue to stir for 30 min after the dropwise addition, then place in a water bath at 35° C., and stir for 3 h to obtain a light yellow glycidyl quaternary ammonium salt intermediate. The molar ratio of triethylamine and epichlorohydrin is 1.41:1.

[0067] Weigh 3.0g of alkali lignin into a three-necked flask, add 10mL of distilled water, add 0.15g of cerium ammonium nitrate after heating up to 70°C, stir for a while, then add the prepared epoxypropyl quaternary ammonium salt intermediate, and stir for 4 hours , to obtain black lignin quaternary ammonium salt solution. The molar ratio of the quaternary ammonium salt intermediate to the alkali lignin is 1.81:1, and the amount of the catalyst is 5% of the mass of the alkali lignin.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com