Vibration-proof Material, Vibration-proof Structure, And Vibration-proof Method

A technology of anti-vibration materials and rubber compositions, applied to springs made of plastic materials, vibration suppression adjustment, non-rotational vibration suppression, etc., can solve problems such as errors and defects, and achieve reduced corrosion and excellent vibration resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~3

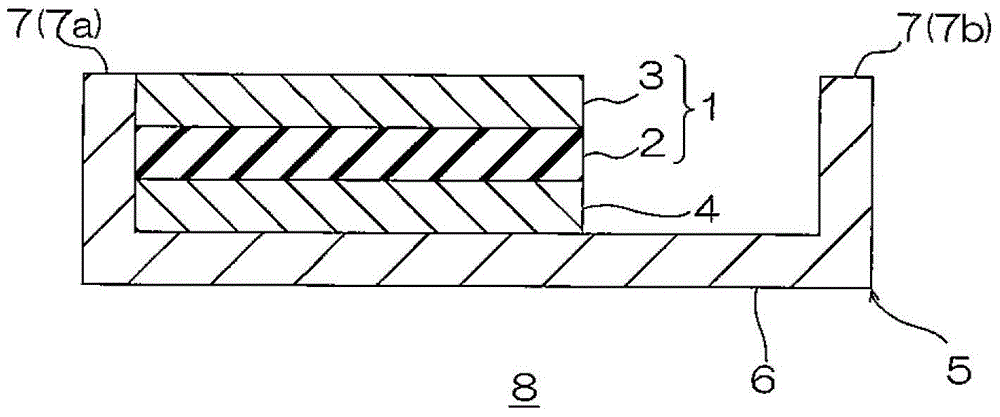

[0119] (1) Manufacture of anti-vibration materials

[0120] According to the compounding amount recorded in the compounding recipe shown in Table 1, polymers, processing aids, pigments, flame retardants, fillers and softeners were compounded and kneaded with a 3L pressurized kneader to prepare a primary mixture.

[0121] Separately mix the crosslinking agent, crosslinking auxiliary agent, foaming agent and foaming auxiliary agent (in the case of comparative examples 1 to 3, vulcanization retarder), mix it with the primary mixture, and mix it with a 10-inch mixing roller. kneading to make a rubber composition (secondary mixture) (kneading process).

[0122] Next, the rubber composition was extruded into a sheet with a thickness of about 8 mm using a single-screw extrusion molding machine (45 mmφ) to produce a rubber composition sheet (forming step).

[0123] Then, the rubber composition sheet was preheated at 140° C. for 20 minutes in a hot air circulation oven. After that, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com