Metal passivation solution and preparation method thereof and hot-dip plated metal material

A technology of metal passivation and alkali metal salt, which is applied in the field of hot-dip metal materials and metal passivation solution, can solve the problem of low corrosion resistance of the protective film, and achieve the effect of excellent storage resistance and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

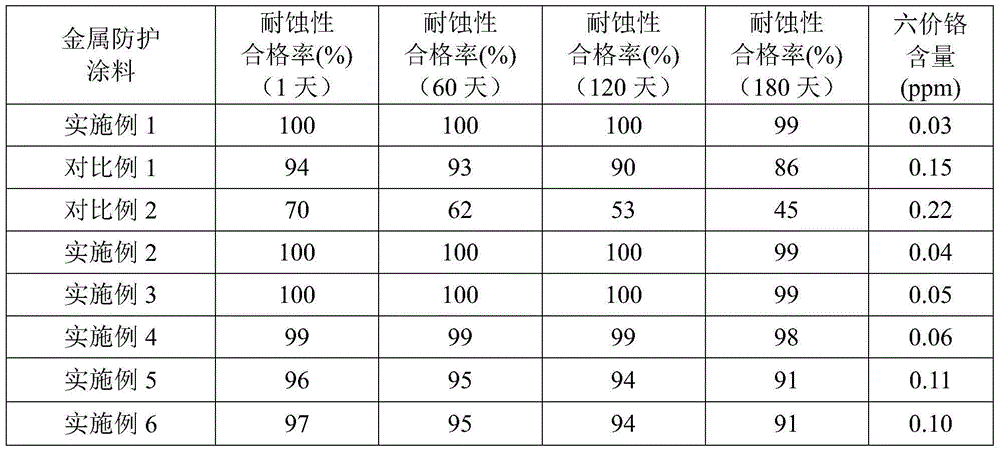

Examples

preparation Embodiment 1

[0050] This preparation example is used to illustrate the method in the reference document CN101608073B to obtain a trivalent chromium source by reducing a hexavalent chromium compound with a reducing agent.

[0051] Add 300 kg of deionized water to a 3000 liter enamel reactor, then add 50 kg of chromic anhydride (CrO 3 ), start the stirrer of the reactor and stir for 10 minutes to dissolve the chromic anhydride. After the chromic anhydride is completely dissolved, add 100 kg of citric acid at room temperature, and start the stirrer quickly to dissolve the citric acid quickly. When the solution does not bubble, it is judged that the reaction is complete, and the required trivalent chromium source is obtained.

Embodiment 1

[0053] Add 10g of phosphonic acid complexing agent (ethylenediaminetetramethylenephosphonic acid, purchased from Shandong Taihe Water Treatment Co., Ltd., No. CAS No.1429-50-1) and 20g of aluminum dihydrogen phosphate to 20g of water, in Mix until uniform at a stirring speed of 1500 rpm to obtain a first solution.

[0054] 7g of trivalent chromium source (the trivalent chromium source prepared in Preparation Example 1, the amount added is calculated by the amount of chromium element), 56g of silica filler (nano silica sol, purchased from Shandong Baite New Material Co., Ltd. company, the brand name is SS-30, and the amount added is based on silica), 65g of water-soluble film-forming resin (made from an equal amount of styrene-acrylic emulsion (purchased from Guangzhou Chaolong Chemical Technology Co., Ltd., the brand name is xy-108b benzene Acrylic emulsion, the solid content is 48% by weight, and the viscosity is 500-1000mPa·s) and fluorocarbon emulsion (purchased from Beijin...

Embodiment 2

[0057] Add 10 g of phosphonic acid complexing agent (pentasodium ethylenediamine tetramethylene phosphonate, purchased from Shandong Taihe Water Treatment Co., Ltd., No. CAS No. 7651-99-2) and 10 g of aluminum dihydrogen phosphate into 30 g of water , and mix until uniform at a stirring speed of 1500 rpm to obtain a first solution.

[0058] 5g of trivalent chromium source (the trivalent chromium source prepared in Preparation Example 1, the amount added is calculated as the amount of chromium element), 65g of silica filler (nano-silica sol, purchased from Shandong Baite New Material Co., Ltd. company, the brand is SS-30, and the amount added is based on silica), 75g of water-soluble film-forming resin (fluorocarbon emulsion (purchased from Beijing Capital Nano Technology Co., Ltd., water-based fluorocarbon emulsion with the brand of SKFT-I, solid The content is 45% by weight, the viscosity is 500-1000mPa·s)) and 10g of sodium phosphate are added to 570g of water, and mixed unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com