Lithium ion liquid flow battery system

A liquid flow battery and lithium-ion technology, applied in the direction of fuel cells, fuel cell additives, regenerative fuel cells, etc., can solve the problems of reducing battery energy efficiency, large mechanical loss, large short-circuit current, etc., to improve safety and battery Coulombic efficiency, reducing equipment cost and power loss, and ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

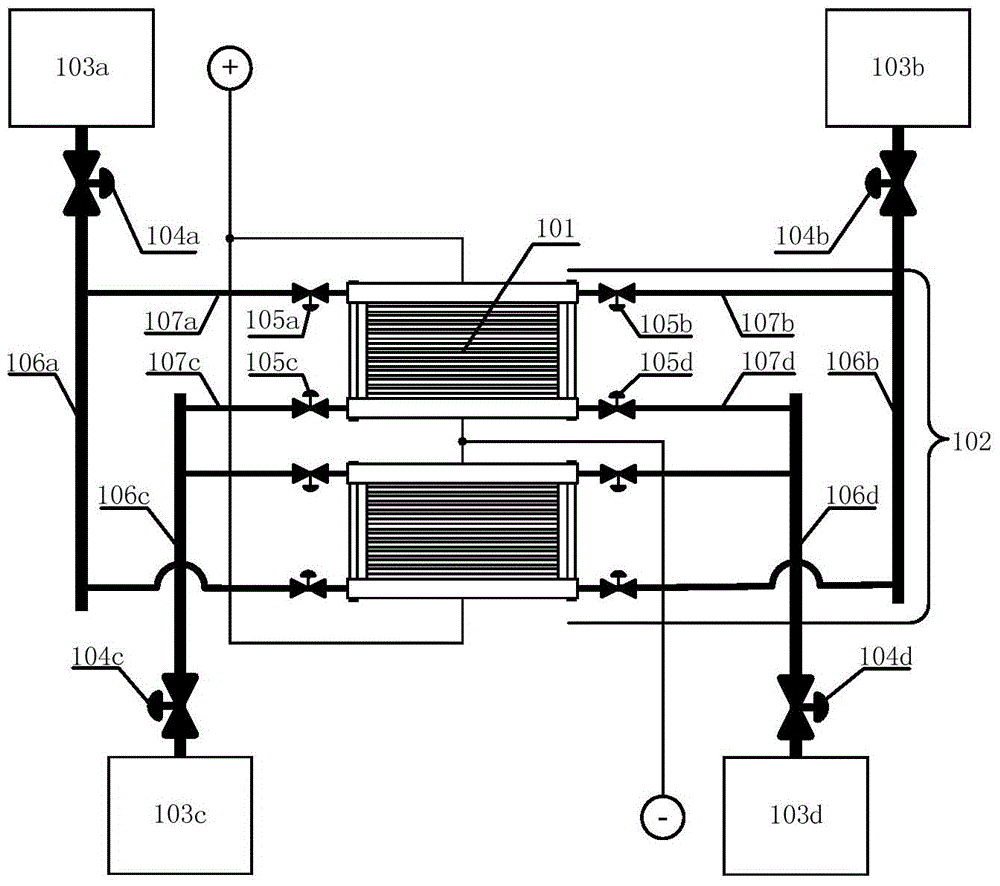

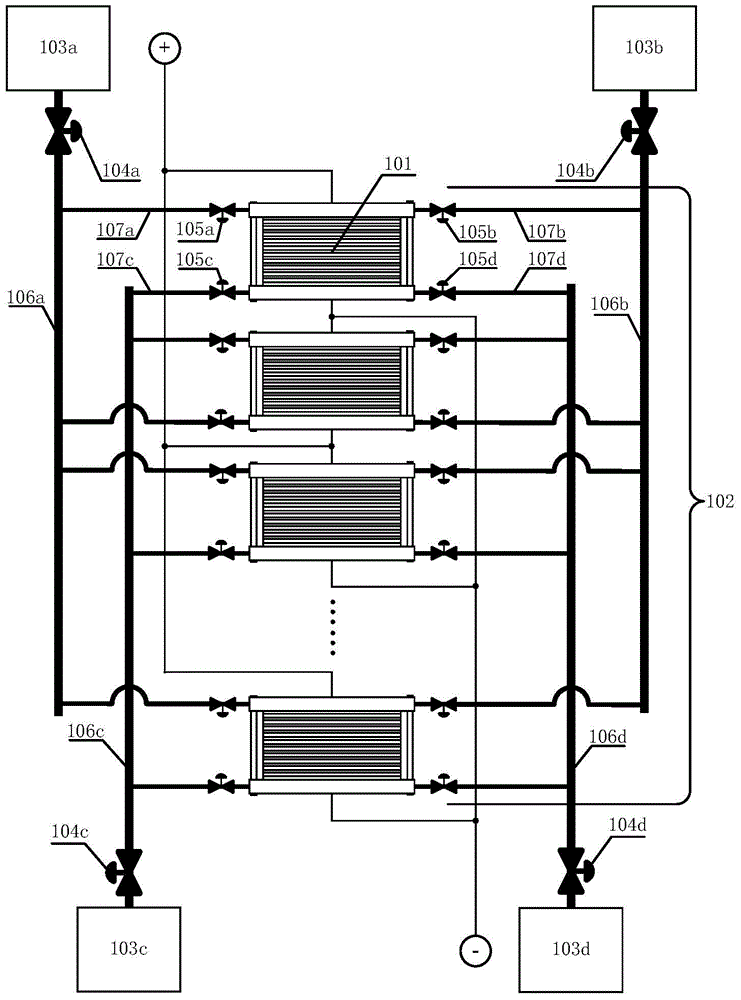

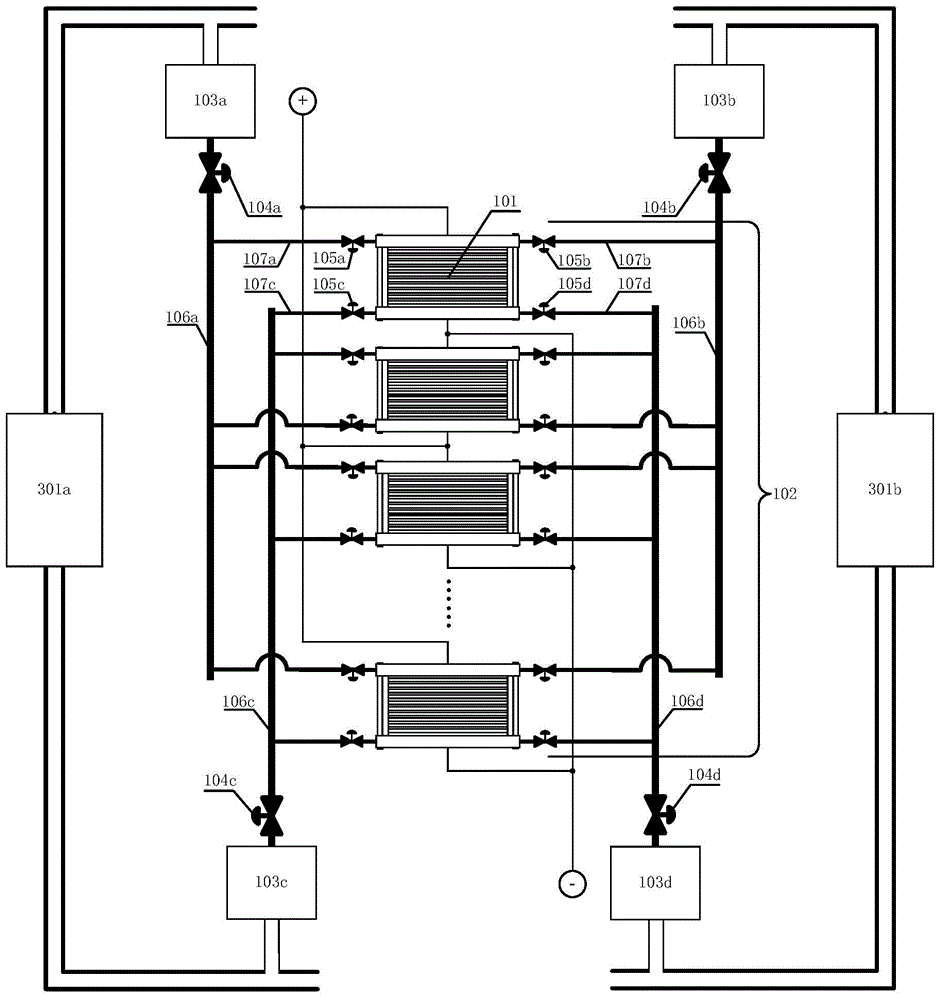

[0037] The structure of the lithium-ion flow battery system in Embodiment 1 of the present invention is as follows: battery cells form battery sub-modules, battery sub-modules form battery modules, and battery modules form battery module groups. This embodiment is a 5kW / 10kWh lithium ion flow battery system. The lithium-ion flow battery system includes a battery module group 301. The battery module group 301 is composed of 15 battery modules 102 connected in series. The road adopts parallel and equidistant bisection mode. Each battery sub-module 101 is composed of 30 battery cells connected in parallel. Battery cell electrode area 1500cm 2 , the thickness is 5mm, the working voltage of the battery unit is 3.2V, and the rated working current is 1.5A, then the rated working voltage of the battery module is 48V, and the rated working current is 360A. The volumes of the first positive electrode liquid storage device 103 a , the second positive electrode liquid storage device 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com