Water-borne wood modifier and preparation method thereof

A modifier and water-borne technology, which is applied in the field of dyeing agents, can solve the problems of difficult wood preservatives, crystallization, and single color, and achieve the effects of low equipment technical requirements, simple production process, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

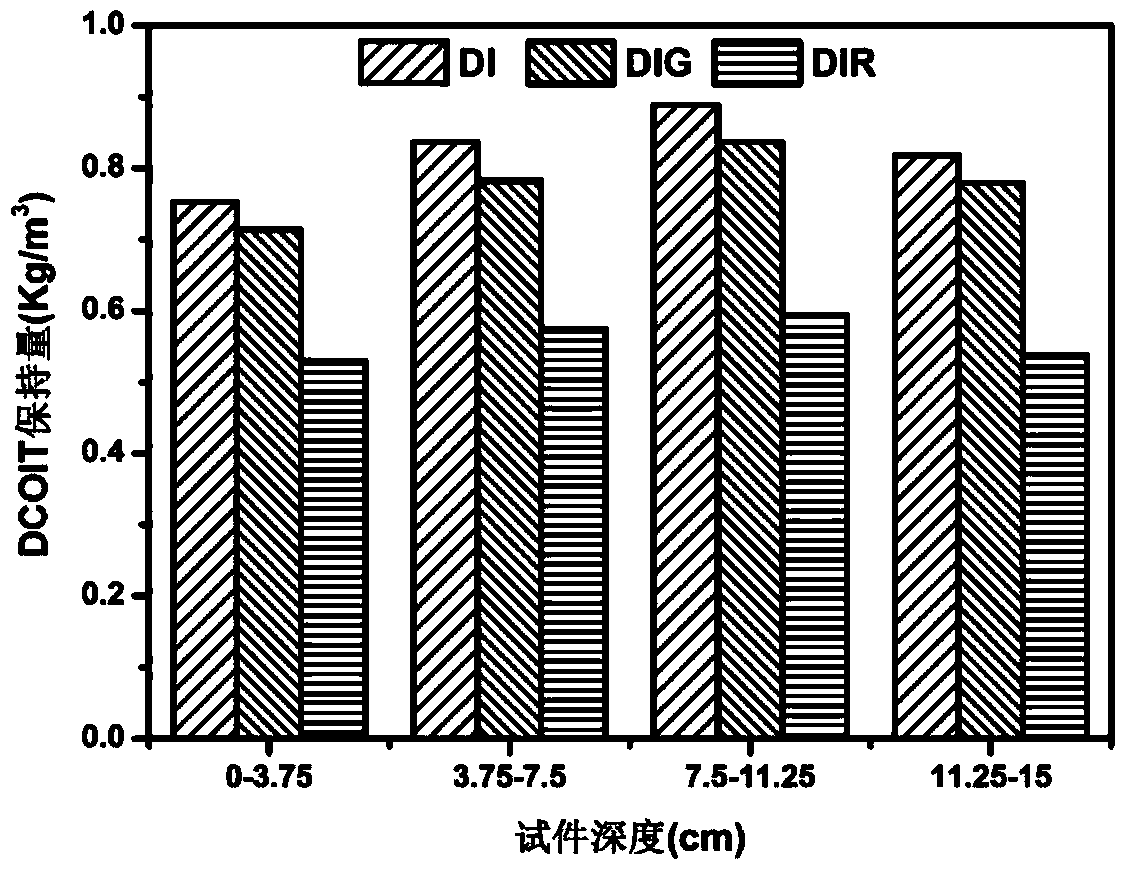

Embodiment 1

[0037] A water-borne wood modifier, which is compounded by antiseptic and antifungal agent and dyeing agent in parts by weight: wherein, the antiseptic and antifungal agent includes the raw materials of the following components: 4,5-dichloro-2 -n-octyl-3-isothiazolinone (DCOIT, Shanghai Sanbo Biochemical Technology Co., Ltd.): 3 g, butyl iodopropynyl carbamate (IPBC, Shanghai Sanbo Biochemical Technology Co., Ltd., concentration: 30%): 7g, sodium dioctyl sulfosuccinate: 2.5g, castor oil polyoxyethylene ether 40 (industrial product, unpurified): 12g, benzyl alcohol: 4g, linolenic acid (analytical pure): 10g, tap water: 150g , the dyeing agent is acid scarlet: 20g.

Embodiment 2

[0039] A water-borne wood modifier, which is compounded by antiseptic and antifungal agent and dyeing agent in parts by weight: wherein, the antiseptic and antifungal agent includes the raw materials of the following components: 4,5-dichloro-2 - n-octyl-3-isothiazolinone (DCOIT, Shanghai Sanbo Biochemical Technology Co., Ltd.): 2 g, butyl iodopropynyl carbamate (IPBC, Shanghai Sanbo Biochemical Technology Co., Ltd., concentration: 30%): 5g, sodium dioctyl sulfosuccinate: 1.0g, castor oil polyoxyethylene ether 40 (industrial product, unpurified): 10g, benzyl alcohol: 6g, linolenic acid (analytical pure): 10g, tap water: 60g , the dyeing agent is acid scarlet: 5g.

Embodiment 3

[0041] A water-borne wood modifier, compounded by antiseptic and antifungal agent and dyeing agent: wherein, the antiseptic and antifungal agent includes the raw materials of the following components: 4,5-dichloro-2-n-octyl- 3 Isothiazolinone (DCOIT, Shanghai Sanbo Biochemical Technology Co., Ltd.): 2g, iodopropynyl butyl carbamate (IPBC, Shanghai Sanbo Biochemical Technology Co., Ltd., concentration is 30%): 4g, dioctyl Sodium sulfosuccinate: 0.5g, castor oil polyoxyethylene ether 40 (industrial product, unpurified): 5g, benzyl alcohol: 4g, linolenic acid (analytical pure): 5g, tap water: 40g, dyeing agent is acidic Big red: 7g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com