Composite vitamin immunopolysaccharide nano micro-emulsion for livestock and poultry as well as preparation method and application of micro-emulsion

A technology of nano-microemulsion and compound vitamin, which is applied in the field of multi-vitamin immune polysaccharide nano-microemulsion for livestock and poultry, which can solve the problems of low animal absorption efficiency, large amount of emulsifier added, easy oxidation and deterioration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

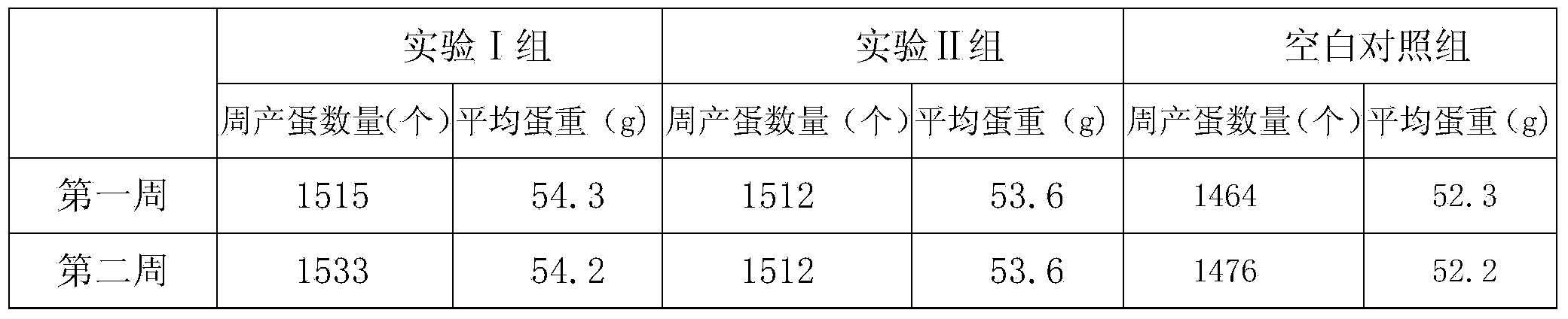

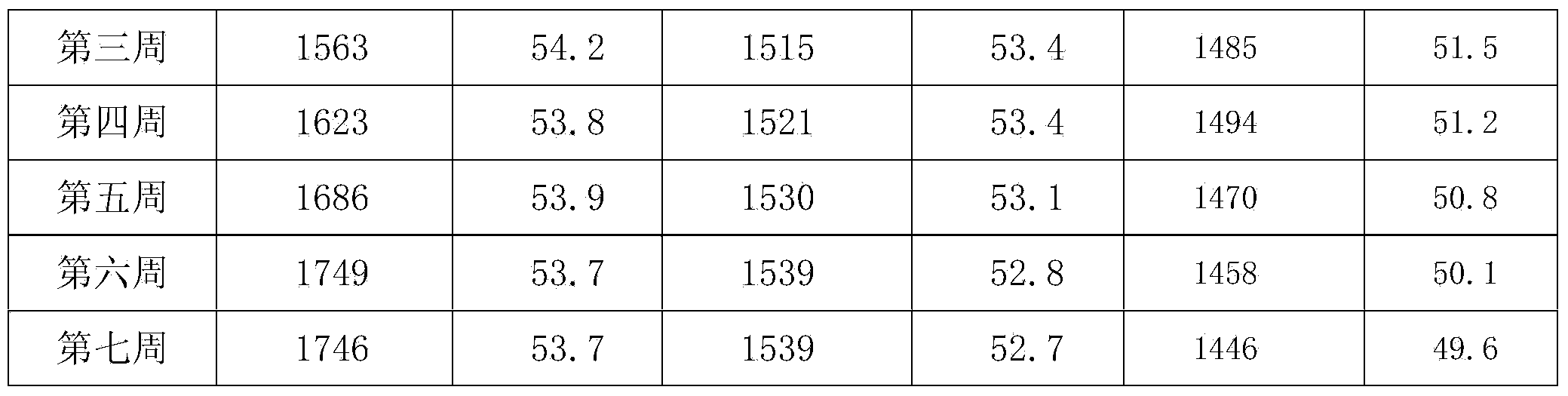

Examples

Embodiment 1

[0037] Weigh 17kg of polyoxyethylene 20 sorbitan monooleate, 17kg of polyoxyethylene 40 hydrogenated castor oil, and 4.7kg of fatty alcohol polyoxyethylene ether, and add them to the batching kettle for stirring, while stirring, add a concentration of 1 million IU 2.1kg of vitamin A acetate oil / g, 9.3kg of 92% DL-ɑ-tocopherol acetate oil, 1 million IU / g vitamin D 3 Oil agent 1.5kg, add 0.7kg of butyl hydroxyanisole, stir well, add ethanol 5.5kg, stir well until a uniform and stable oil phase is formed.

[0038] Inject deionized water 736kg in another batching kettle, add sodium bisulfite menadione (K 3 )3.5kg, Vitamin B 1 2.3kg, Vitamin B 2 3kg, Vitamin B 6 5kg, folic acid 0.5kg, vitamin B 12 10g, calcium pantothenate 13kg, nicotinamide 30kg, D-biotin 0.17kg, fructooligosaccharides 110kg, saccharicterpenes 12kg, sodium sulfite 0.6kg, sodium benzoate 4kg, stir well until a uniform and stable water phase is formed.

[0039] Inject the above oil phase and water phase into th...

Embodiment 2

[0046] The formula is substantially the same as that of Example 1, except that the fructooligosaccharides are changed to 120 kg and the saccharoterpenes are changed to 15 kg, other components are not changed, and the preparation method is the same as that of Example 1.

Embodiment 3

[0048] The formula is substantially the same as that of Example 1, except that the fructooligosaccharides are changed to 130 kg and the saccharoterpenes are changed to 15 kg, and other components are not changed. The preparation method is the same as that of Example 1, and Sample 1 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com