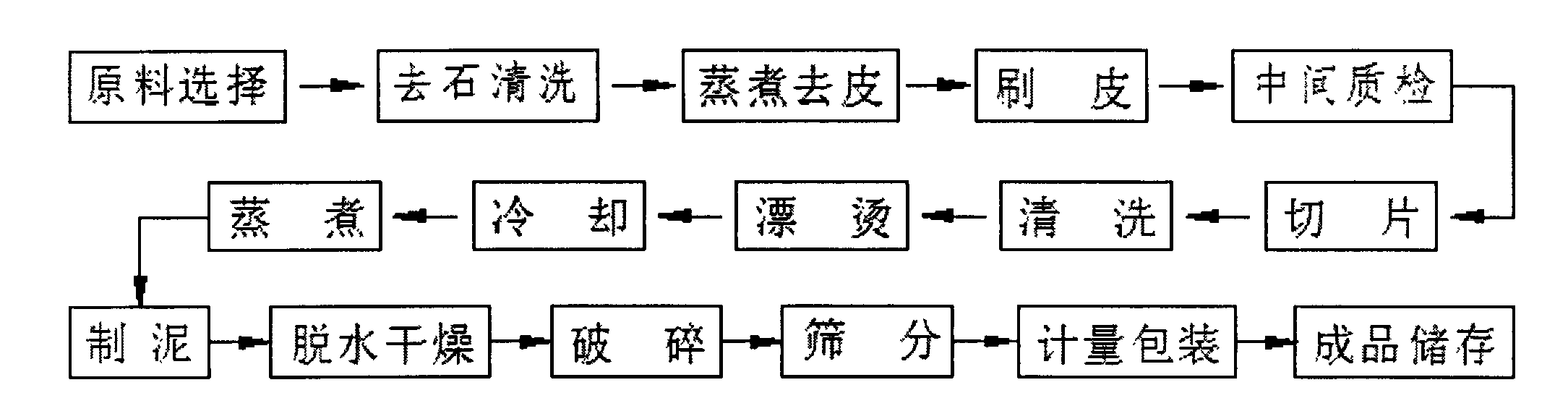

Purple sweet potato cooked whole flour production line

A production line, purple potato technology, applied in food processing, food preparation, vegetable or fruit peeling, etc., can solve the problems of reducing the water content of purple potato mud, large equipment investment, dust pollution, etc., and achieve economical and reasonable equipment configuration and automation The effect of high degree and high operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

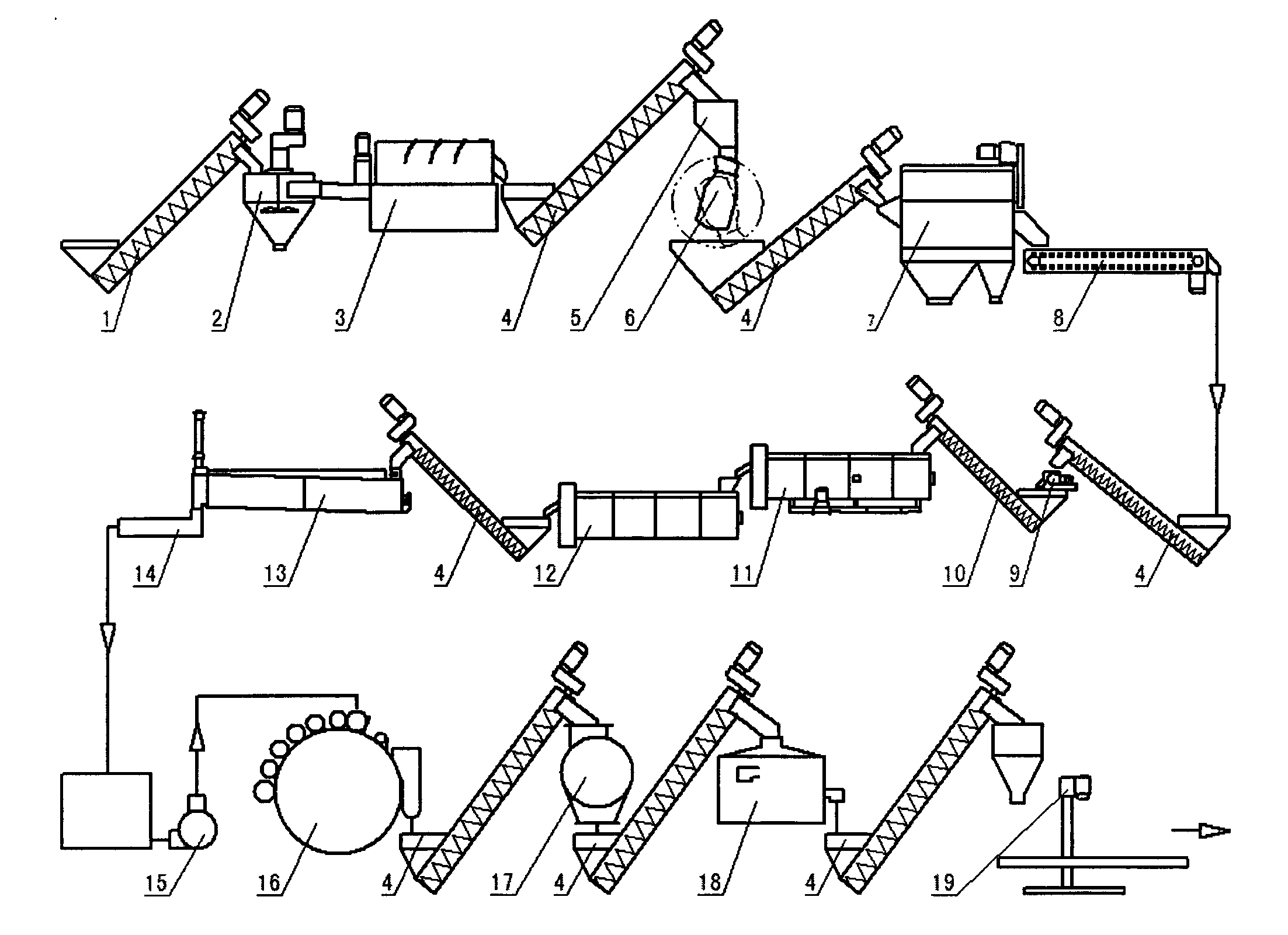

[0028] Example 1 figure 2 Shown is the schematic diagram arranged according to the production process of the present invention, a production line of ripened purple sweet potato powder, when carrying out continuous scale production of ripened purple sweet potato powder, the equipment configured according to each step of the production process:

[0029] The purple sweet potato that has passed the raw material selection process is lifted by the soil and rock removal screw elevator (1) and filtered for part of the soil and rocks, and then enters the cyclone destoner cleaning machine (2) in the cleaning process: in the cyclone separator In the stable horizontal circular rotating water flow field, the potato pieces, sediment and stones in the purple potato raw material are quickly separated and discharged from their respective outlets; the water used by this machine and the subsequent cage cleaning machine is The configured water supply and drainage circulation system is supplied, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com