D-type dry powder extinguishing agent and preparation method thereof

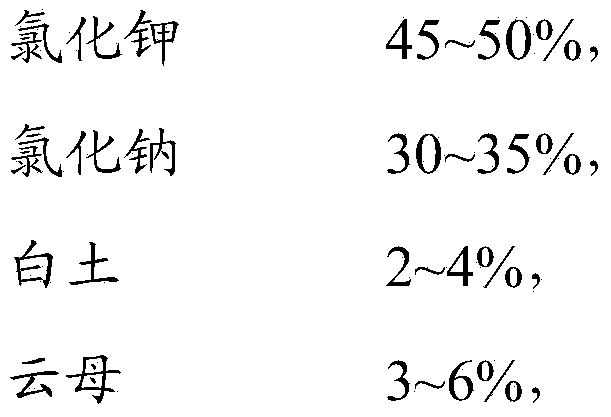

A technology of dry powder fire extinguishing agent and weight percentage, which is applied in the direction of fire prevention equipment, etc. It can solve the problems of expensive imported dry powder, failure to extinguish metal fires, and failure to achieve fire extinguishing purposes, and achieve low price, good compactness, and fast fire extinguishing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

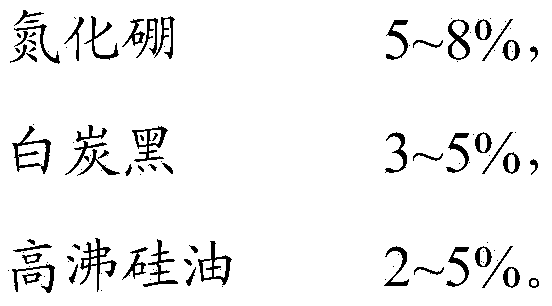

Embodiment 1

[0022] A kind of preparation method of class D dry powder fire extinguishing agent comprises the following steps:

[0023] 1) Add 48% by weight of sodium chloride and 32% by weight of potassium chloride into the mixing pot, stir for 10 minutes, then add 1% by weight of high-boiling silicone oil by spraying, stir evenly, and heat at 100°C Heating at constant temperature until the water content of the mixture is lower than 0.2%, stopping heating and cooling to normal temperature to obtain product A;

[0024] 2) The product A is pulverized by a ring roller mill until more than 80% of the particles have a particle size of 15-40 microns to obtain the product B;

[0025] 3) Add 3% clay by weight, 4% mica by weight, 6% boron nitride by weight and the product B into the reaction vessel, heat up and stir, when the temperature of the mixture rises to 55°C , add 2% by weight of high-boiling silicone oil, stir evenly, then add 4% by weight of white carbon black, heat at a constant temper...

Embodiment 2

[0027] A kind of preparation method of class D dry powder fire extinguishing agent comprises the following steps:

[0028] 1) Add 50% by weight of sodium chloride and 30% by weight of potassium chloride into the mixing pot, stir for 8 minutes, then add 1% by weight of high-boiling silicone oil by spraying, stir evenly, and heat at 110°C Heating at constant temperature until the water content of the mixture is lower than 0.2%, stopping heating and cooling to normal temperature to obtain product A;

[0029] 2) The product A is pulverized by a ring roller mill until more than 80% of the particles have a particle size of 15-40 microns to obtain the product B;

[0030] 3) Add 4% white clay by weight, 6% mica by weight, 5% boron nitride by weight and the product B into the reaction vessel, heat up and stir, when the mixture is heated up to 55°C , add 1% by weight of high-boiling silicone oil, stir evenly, then add 3% by weight of white carbon black, heat at a constant temperature a...

Embodiment 3

[0032] A kind of preparation method of class D dry powder fire extinguishing agent comprises the following steps:

[0033] 1) Add 45% by weight of sodium chloride and 35% by weight of potassium chloride into the mixing pot, stir for 15 minutes, then add 2% by weight of high-boiling silicone oil by spraying, stir evenly, and heat at 85°C Heating at constant temperature until the water content of the mixture is lower than 0.2%, stopping heating and cooling to normal temperature to obtain product A;

[0034] 2) The product A is pulverized by a ring roller mill until more than 80% of the particles have a particle size of 15-40 microns to obtain the product B;

[0035] 3) Add 2% clay by weight, 3% mica by weight, 6% boron nitride by weight and the product B into the reaction vessel, heat up and stir, when the mixture is heated to 55°C , add 2% by weight of high-boiling silicone oil, stir evenly, then add 5% by weight of white carbon black, heat at a constant temperature of 85°C un...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap