Magnetic copper and bismuth catalyst and preparation method thereof

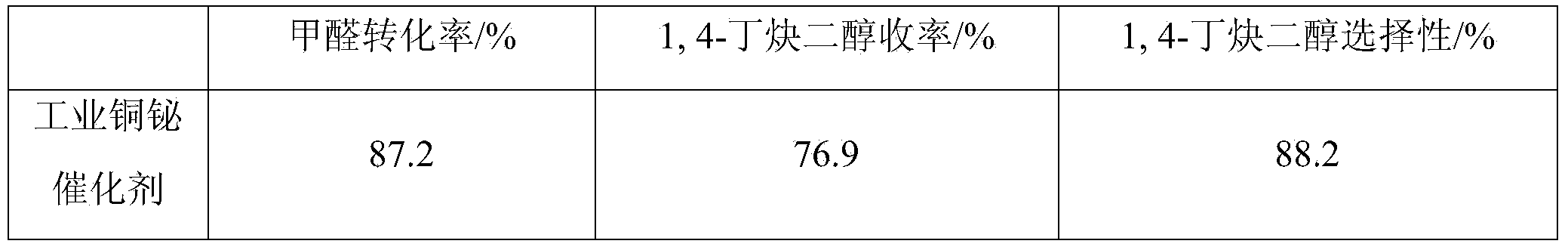

A copper-bismuth catalyst and catalyst technology are applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., which can solve the problems of difficult separation of catalysts, and achieve the effects of shortening production cycle, simple and easy operation, and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation method of magnetic copper-bismuth catalyst of the present invention comprises the following steps:

[0021] (1) Take 0.015m2ol Fe(NO 3 ) 3 9H 2 O, 0.12mol of sodium acetate, dissolved in 100mL of ethylene glycol, configuration Fe 3+ Concentration is 0.15mol / L, Na + Ethylene glycol solution with a concentration of 1.2 mol / L was placed in a hydrothermal kettle, reacted at 150°C for 24 hours, cooled to room temperature, and the generated Fe 3 o 4 Perform magnetic separation, wash several times with distilled water, and dry in a vacuum oven at 40°C; the obtained Fe 3 o 4 The grain size is 30nm;

[0022] (2) Weigh 6.07g Cu(NO 3 ) 2 ·3H 2 O, 0.21g Bi(NO 3 ) 3 ·5H 2 O, 15.90g Mg(NO 3 ) 2 ·6H 2 O, dissolved in water, prepared into a mixed solution with a total concentration of metal ions of 0.5mol / L;

[0023] (3) Take 11.50g tetraethyl orthosilicate and configure SiO 2 Concentration is the ethanol solution of 2.0mol / L, add the Fe ...

Embodiment 2

[0026] Embodiment 2: the preparation method of magnetic copper-bismuth catalyst of the present invention comprises the following steps:

[0027] (1) Take 0.015mol Fe(NO 3 ) 3 9H 2 O, 0.12mol of sodium acetate, dissolved in 100mL of ethylene glycol, configuration Fe 3+ Concentration is 0.15mol / L, Na+ Ethylene glycol solution with a concentration of 1.2 mol / L was placed in a hydrothermal kettle, reacted at 180°C for 24 hours, cooled to room temperature, and the generated Fe 3 o 4 Perform magnetic separation, wash several times with distilled water, and dry in a vacuum oven at 60°C; the obtained Fe 3 o 4 The grain size is 35nm;

[0028] (2) Weigh 6.07g Cu(NO 3 ) 2 ·3H 2 O, 0.21g Bi(NO 3 ) 3 ·5H 2 O, 15.90g Mg(NO 3 ) 2 ·6H 2 O is dissolved in water and prepared into a mixed solution with a total concentration of metal ions of 1.0 mol / L;

[0029] (3) Take 11.50g tetraethyl orthosilicate and configure SiO 2 Concentration is the ethanol solution of 1.8mol / L, add the ...

Embodiment 3

[0032] Embodiment 3: the preparation method of magnetic copper-bismuth catalyst of the present invention comprises the following steps:

[0033] (1) Take 0.03mol of FeCl 3 9H 2 O, 0.24mol of sodium acetate, dissolved in 150mL of ethylene glycol, configuration Fe 3+ Concentration is 0.2mol / L, Na + Ethylene glycol solution with a concentration of 1.6mol / L was placed in a hydrothermal kettle, reacted at 180°C for 20h, cooled to room temperature, and the formed Fe 3 o 4 Perform magnetic separation, wash several times with distilled water, and dry in a vacuum oven at 60°C; the obtained Fe 3 o 4 The grain size is 40nm;

[0034] (2) Weigh 5.36g CuCl 2 2H 2 O, 0.27g BiCl 3 , 10.08g MgCl 2 ·6H 2 O, dissolved in water, prepared into a mixed solution with a total concentration of metal ions of 1.5mol / L;

[0035] (3) Take 9.5g ethyl orthosilicate and configure SiO 2 Concentration is the ethanol solution of 1.2mol / L, adds the Fe prepared in 1.5g (1) 3 o 4 , ultrasonically di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com