Preparation method and application of Fe4I3O24H15 visible-light-induced photocatalyst

A fe4i3o24h15, visible light technology, applied in the field of photocatalysis, can solve problems such as hindering the practical process of photocatalysis technology, low activity of organic pollutants, and reduced photocatalytic activity, and achieves excellent photocatalytic performance, high catalytic activity, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is the present invention Fe 4 I 3 o 24 h 15 Specific examples of photocatalyst preparation and application research, the following examples are intended to illustrate the present invention rather than limit the present invention.

[0024] (1) Fe 4 I 3 o 24 h 15 Preparation of photocatalyst:

[0025] Take 10mmol of Fe(NO 3 ) 3 9H 2 O was dissolved in 50 mL of deionized water, and then 7.5 mL of concentrated nitric acid (concentration: 65 wt %) was added thereto to obtain an acidic ferric nitrate solution. Take 10mmol of NaIO 4 Dissolve in 50mL deionized water to obtain sodium metaperiodate solution. Heat the ferric nitrate solution and sodium metaperiodate solution to 80°C, and then mix the two solutions under stirring to obtain a precipitate. After the precipitate was separated, it was dried at 60°C for 5 h to obtain Fe 4 I 3 o 24 h 15 sample.

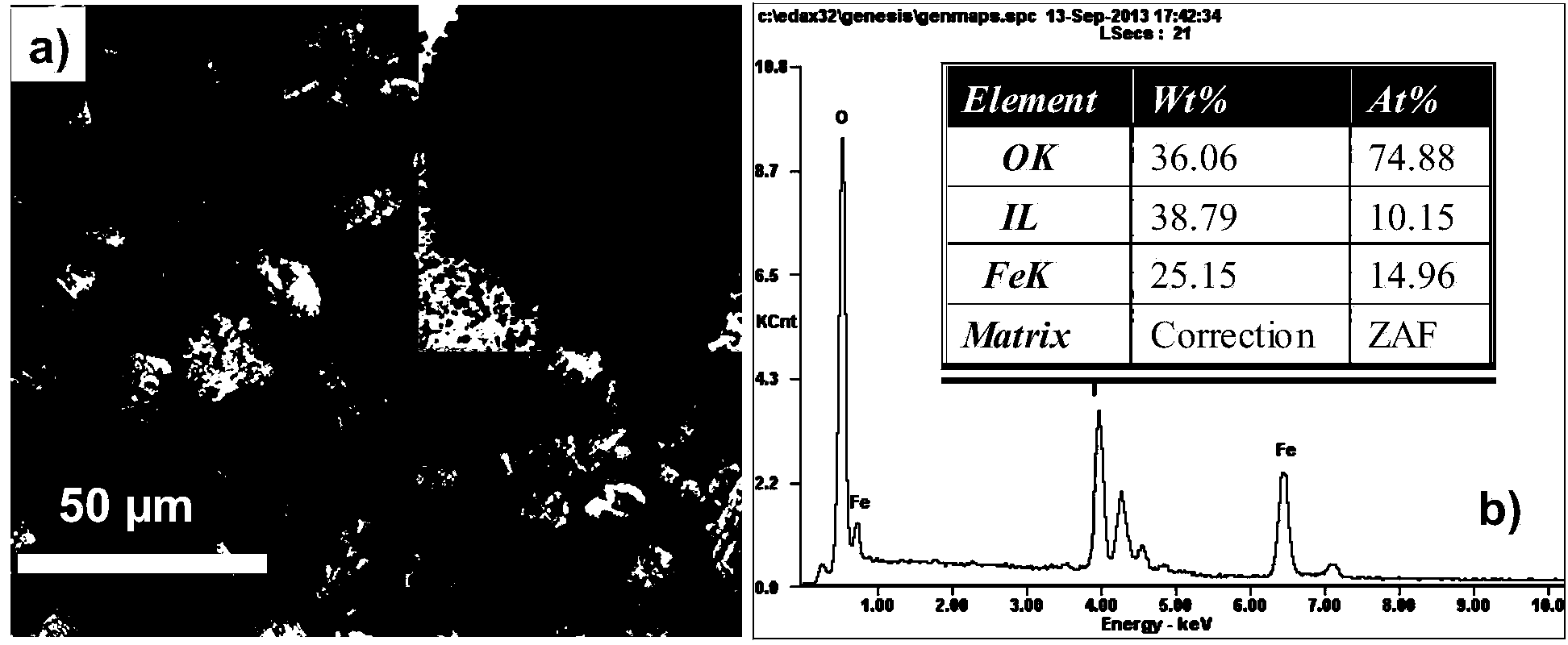

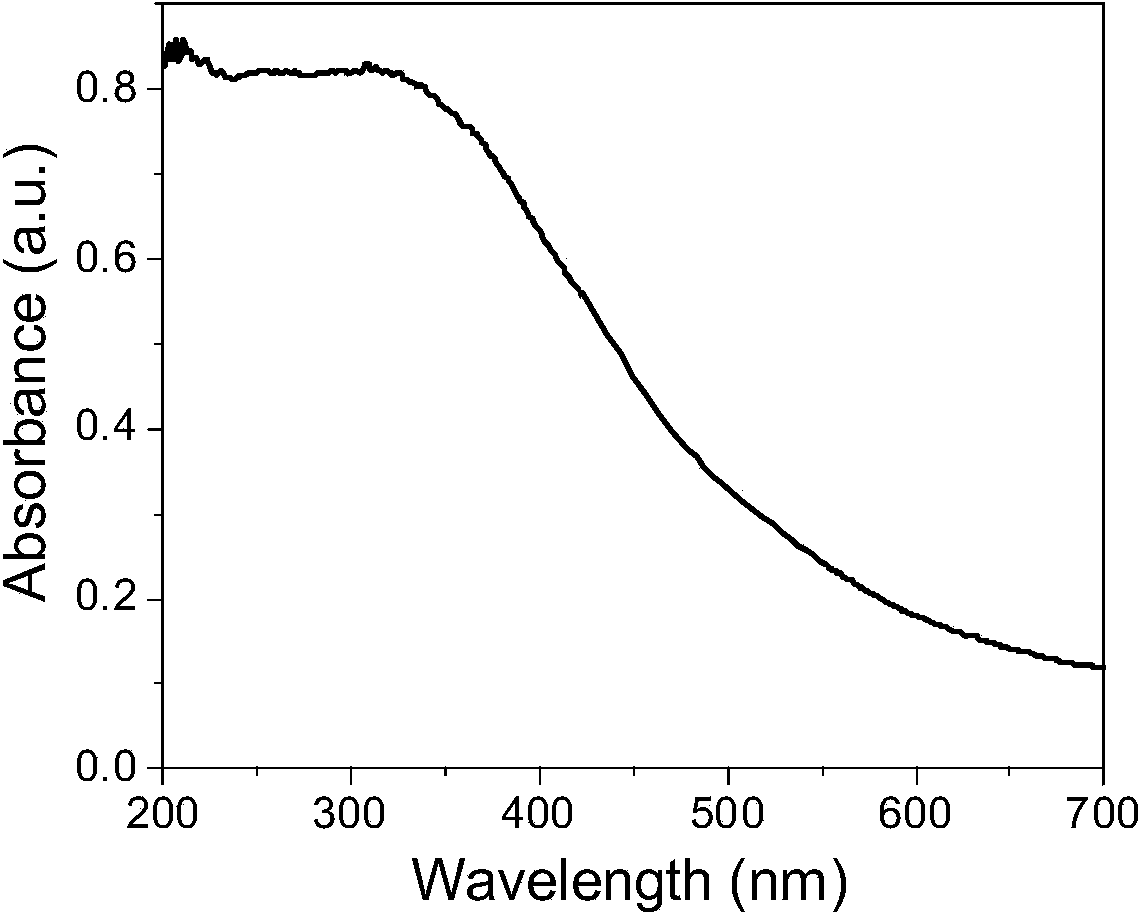

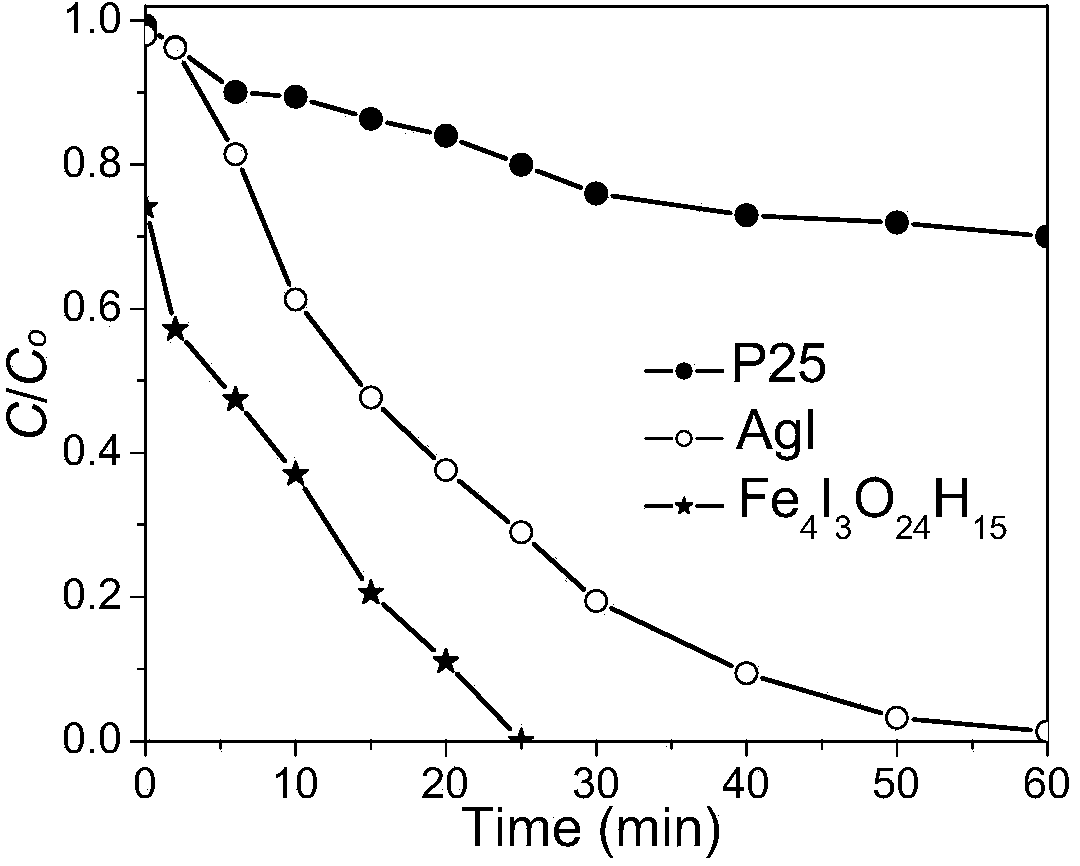

[0026] (2) Fe 4 I 3 o 24 h 15 Characterization of photocatalysts:

[0027] from figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com