Fret saw with grinding materials and manufacturing method thereof

A material line and belt grinding technology, which is applied to metal sawing equipment, tool manufacturing of sawing machine devices, manufacturing tools, etc., can solve the problems of abrasive particles falling off, and achieve the effect of lowering temperature, not easy to drop particles, and improving bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

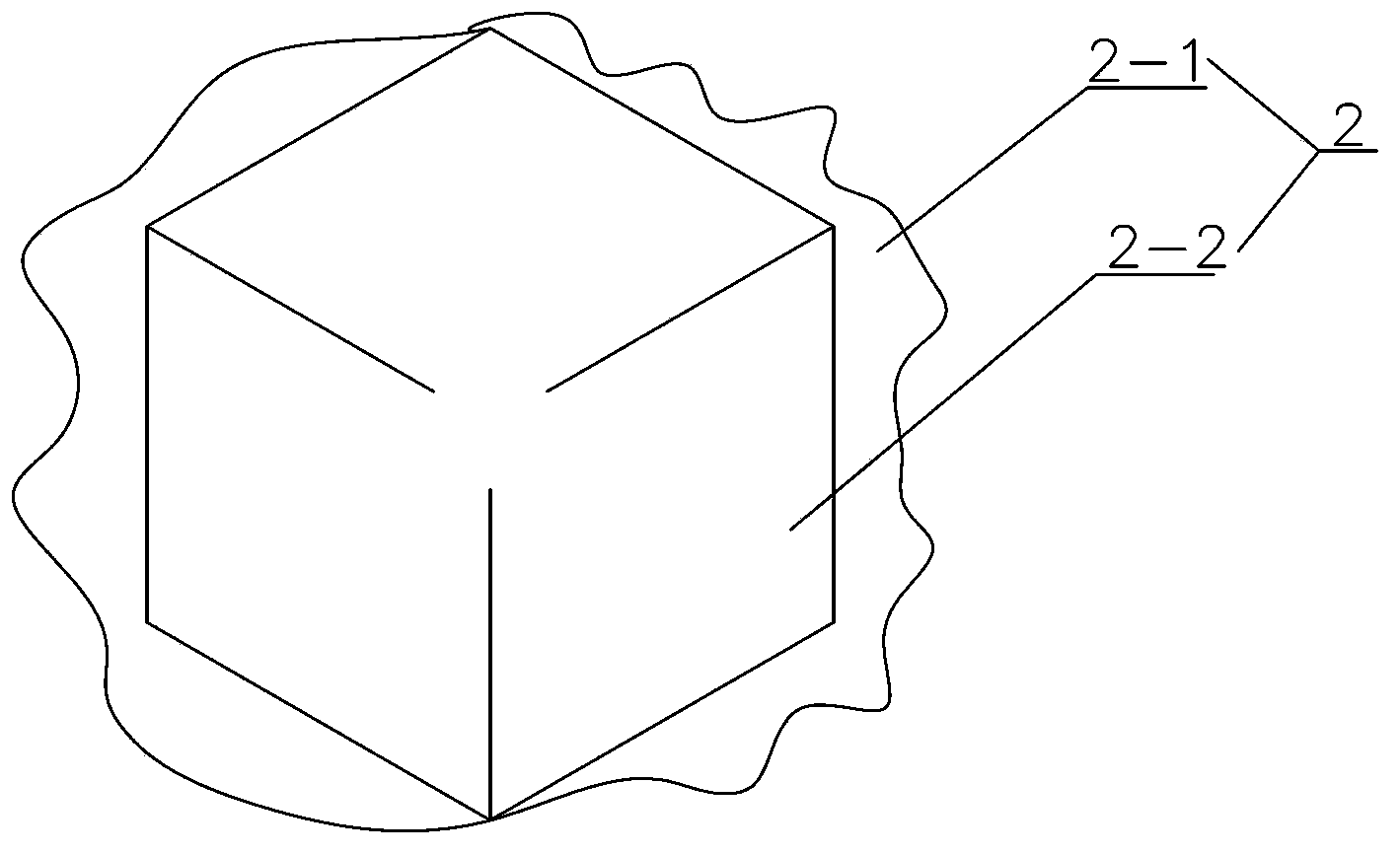

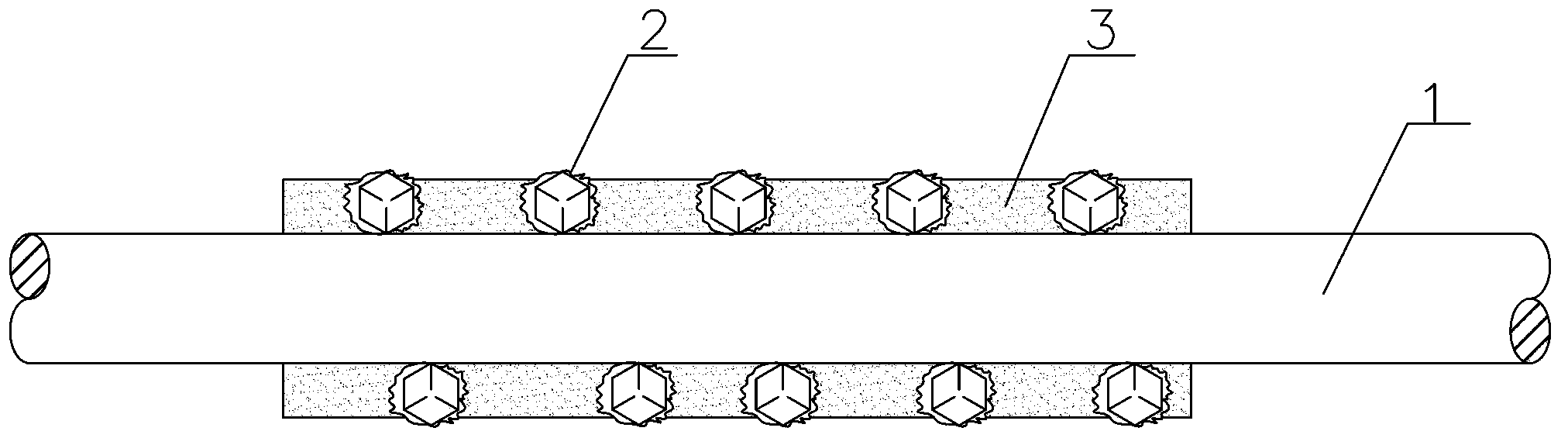

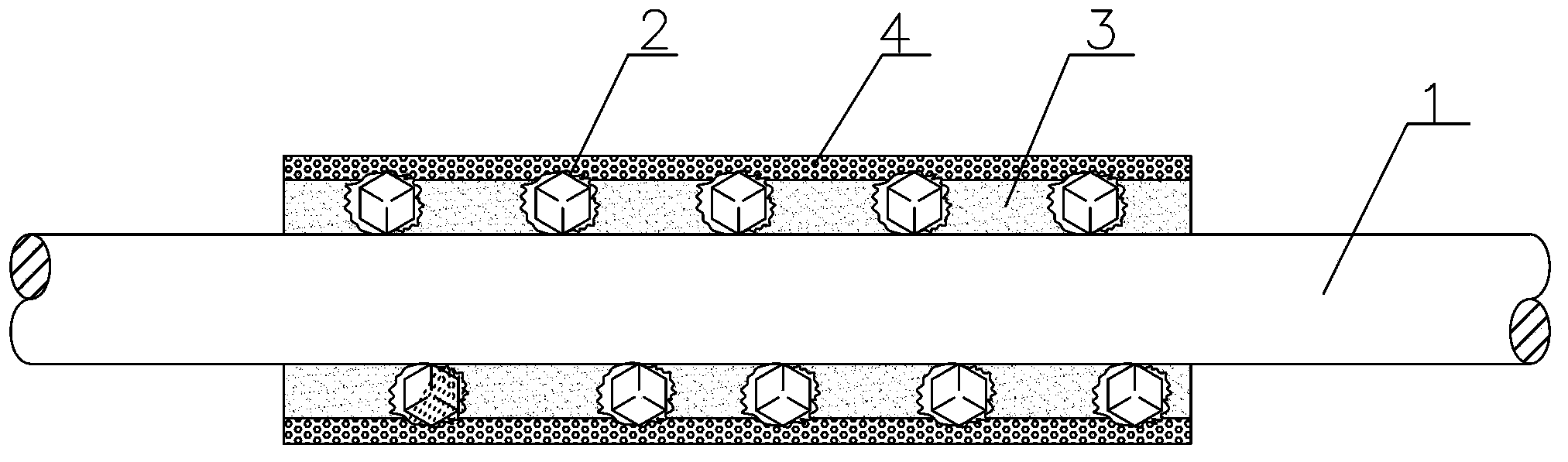

[0046] Such as figure 1 , 2 As shown in , 4, an abrasive wire saw includes a metal wire 1 and a bearing layer 3 coated on the surface of the metal wire 1 containing metal compound abrasives 2 . The surface of the metallized abrasive 2 is fully or partially coated with the abrasive grains 2-2 of the metallized layer 2-1, and the metallized layer 2-1 and the surface layer of the abrasive grains 2-2 have chemical bonds other than the physical binding force For linking, the abrasive particles 5 are made of diamond particles, and the metal wire 1 is a single wire made of galvanized steel wire.

[0047] The preparation method of the abrasive wire saw is as follows:

[0048] 1) Adhesive blending process, dissolving phenolic resin in ethanol at a certain concentration, stirring evenly, adjusting the concentration according to viscosity and fluidity (the greater the concentration, the thicker the metal compound layer coated with diamond obtained);

[0049] 2) Coating process, put the ...

Embodiment 2

[0057] Such as figure 1 , 2 As shown in , 4, an abrasive wire saw includes a metal wire 1 and a bearing layer 3 coated on the surface of the metal wire 1 containing metal compound abrasives 2 . The surface of the metallized abrasive 2 is fully or partially coated with the abrasive grains 2-2 of the metallized layer 2-1, and the metallized layer 2-1 and the surface layer of the abrasive grains 2-2 have chemical bonds other than the physical binding force For linking, the abrasive particles 5 are made of diamond particles, and the metal wire 1 is a single wire made of brass-plated steel wire.

[0058] The preparation method of the abrasive wire saw is as follows:

[0059] 1) Adhesive preparation process, dissolve polyethylene glycol 10000 in methanol, and stir evenly;

[0060] 2) Coating process, put the diamond in a colander, then immerse in the solution prepared by the adhesive, after shaking and mixing, lift the colander, and leak the excess solution, so that the surface o...

Embodiment 3

[0068] Such as figure 1 , 2 As shown in , 4, an abrasive wire saw includes a metal wire 1 and a bearing layer 3 coated on the surface of the metal wire 1 containing metal compound abrasives 2 . The surface of the metallized abrasive 2 is fully or partially coated with the abrasive grains 2-2 of the metallized layer 2-1, and the metallized layer 2-1 and the surface layer of the abrasive grains 2-2 have chemical bonds other than the physical binding force Link, the abrasive particles 5 are made of silicon carbide particles, and the metal wire 1 is made of stainless steel wire.

[0069] The preparation method of the abrasive wire saw is as follows:

[0070] 1) Adhesive preparation process, adding epoxy resin to ethanol and stirring evenly;

[0071] 2) Coating process, put silicon carbide particles in a colander, then immerse in the solution prepared by the adhesive, after shaking and mixing, lift the colander, and leak the excess solution, so that the surface of the silicon ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com