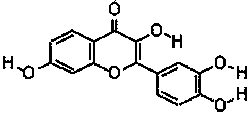

Process for extracting fisetin from cotinus coggygria

A technology of fisetin and cotinus, applied in organic chemistry and other directions, can solve the problems of complex process and high cost, achieve the effect of short cycle, avoid sample loss, and solve the effect of long separation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 5kg of dried branches and leaves of Cotinus cotinus, crush them, pass through a 40-mesh sieve, put them into the equipment cavity, add 8 times the amount of 60% ethanol for extraction, ultrasonic for 20 minutes, the temperature is 30°C, the ultrasonic power is 800w, filter, and the filtrate is concentrated under reduced pressure until it has no alcohol smell. The concentrated solution is passed through an AB-8 macroporous resin column, washed with water until there is no alcohol smell, and then eluted with 6BV50% ethanol, and the alcohol eluent is concentrated and dried to obtain a dry product;

[0022] Mix ethyl acetate-n-butanol-water at a volume ratio of 3:1:4, mix evenly and let stand to separate layers, the lower phase is the mobile phase, the upper phase is the stationary phase, the dried matter is dissolved in the lower phase, and the stationary phase Pump the chromatographic column fully, then adjust the speed of the main engine to 1000rmp, pump in the mobil...

Embodiment 2

[0024] Take 10kg of dried branches and leaves of cotinus sumac, crush them, pass through a 40-mesh sieve, put them into the equipment cavity, add 10 times the amount of 80% ethanol for extraction, ultrasonic for 40 minutes, the temperature is 30°C, the ultrasonic power is 600w, filter, and the filtrate is concentrated under reduced pressure until it has no alcohol smell. The concentrated solution is passed through a XAD-4 macroporous resin column, washed with water until there is no alcohol smell, and then eluted with 8BV60% ethanol, and the alcohol eluent is concentrated and dried to obtain a dry product;

[0025] Mix ethyl acetate-n-butanol-water at a volume ratio of 6:5:7, mix evenly and then let stand to separate. The lower phase is the mobile phase, the upper phase is the stationary phase, and the dried matter is dissolved in the lower phase. Pump the chromatographic column fully, then adjust the speed of the main engine to 900rmp, pump in the mobile phase, the flow rate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com