Method for preparing magnetic/core-shell molecularly imprinted adsorbent employing miniemulsion polymerization

A technology of miniemulsion polymerization and molecular imprinting, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of lack of specific recognition ability and poor selectivity, and achieve low magnetic leakage, good magnetic response properties, and fast separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. A method for preparing a magnetic / core-shell molecularly imprinted adsorbent by miniemulsion polymerization, the preparation method of which is carried out according to the following steps:

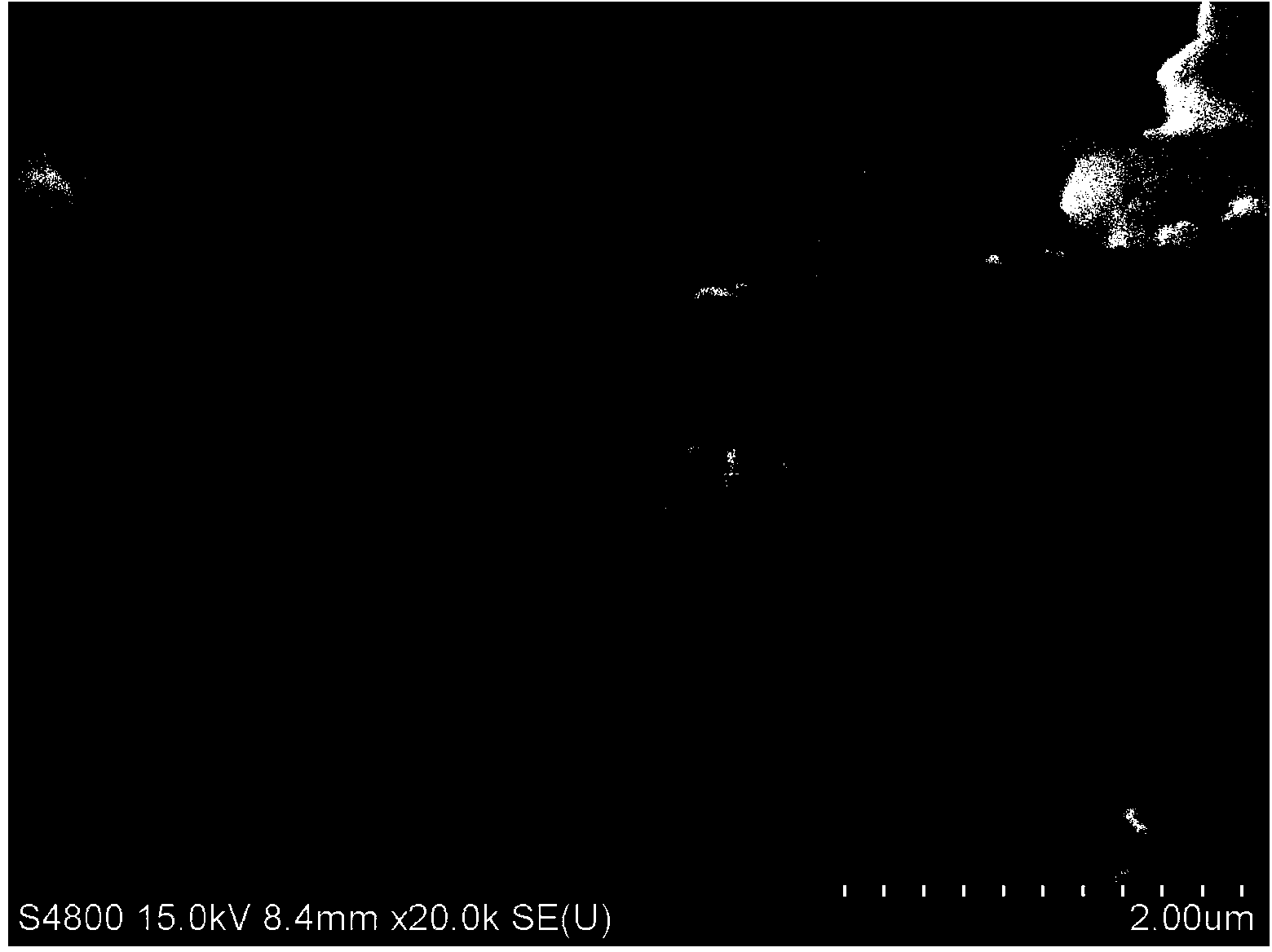

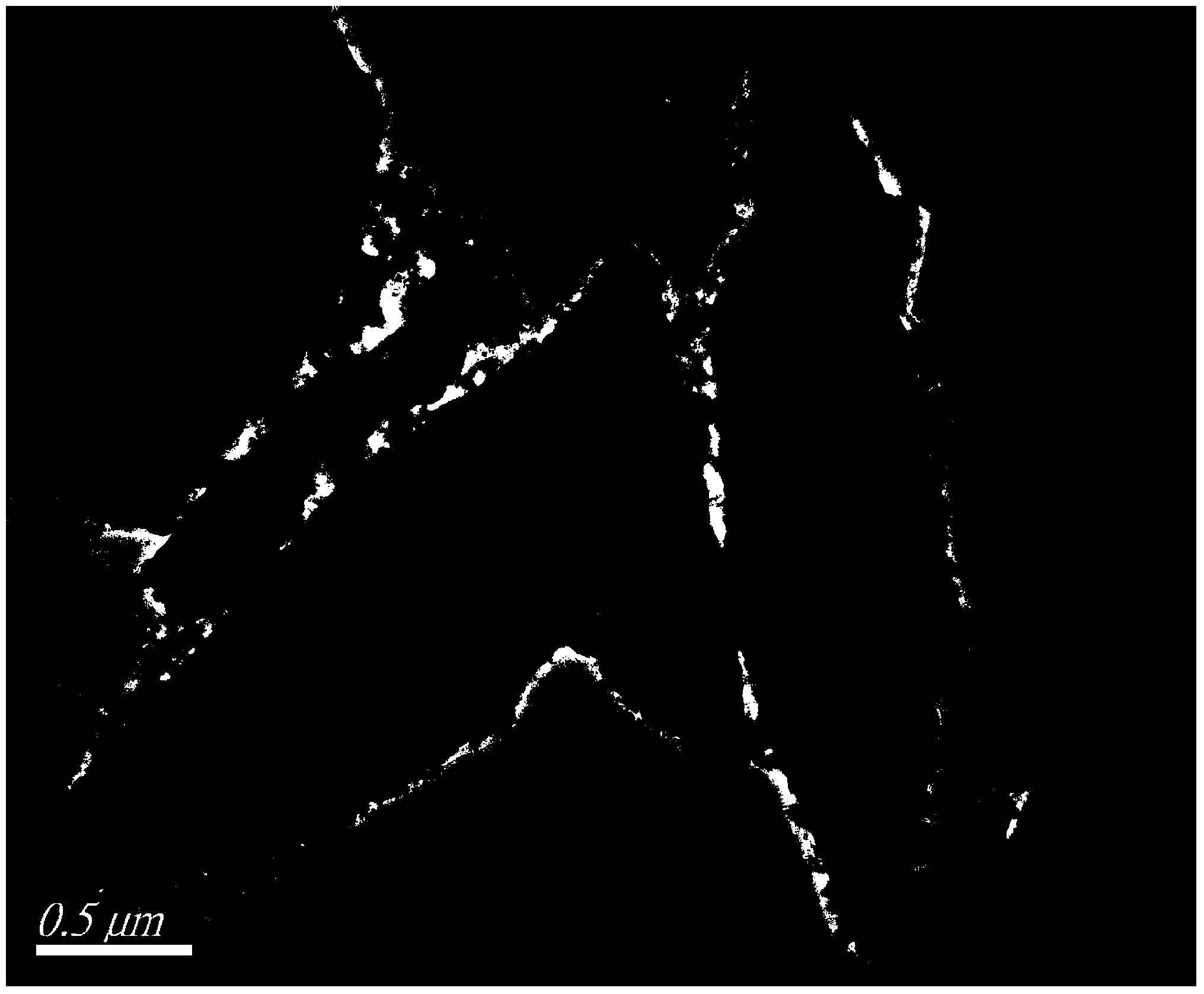

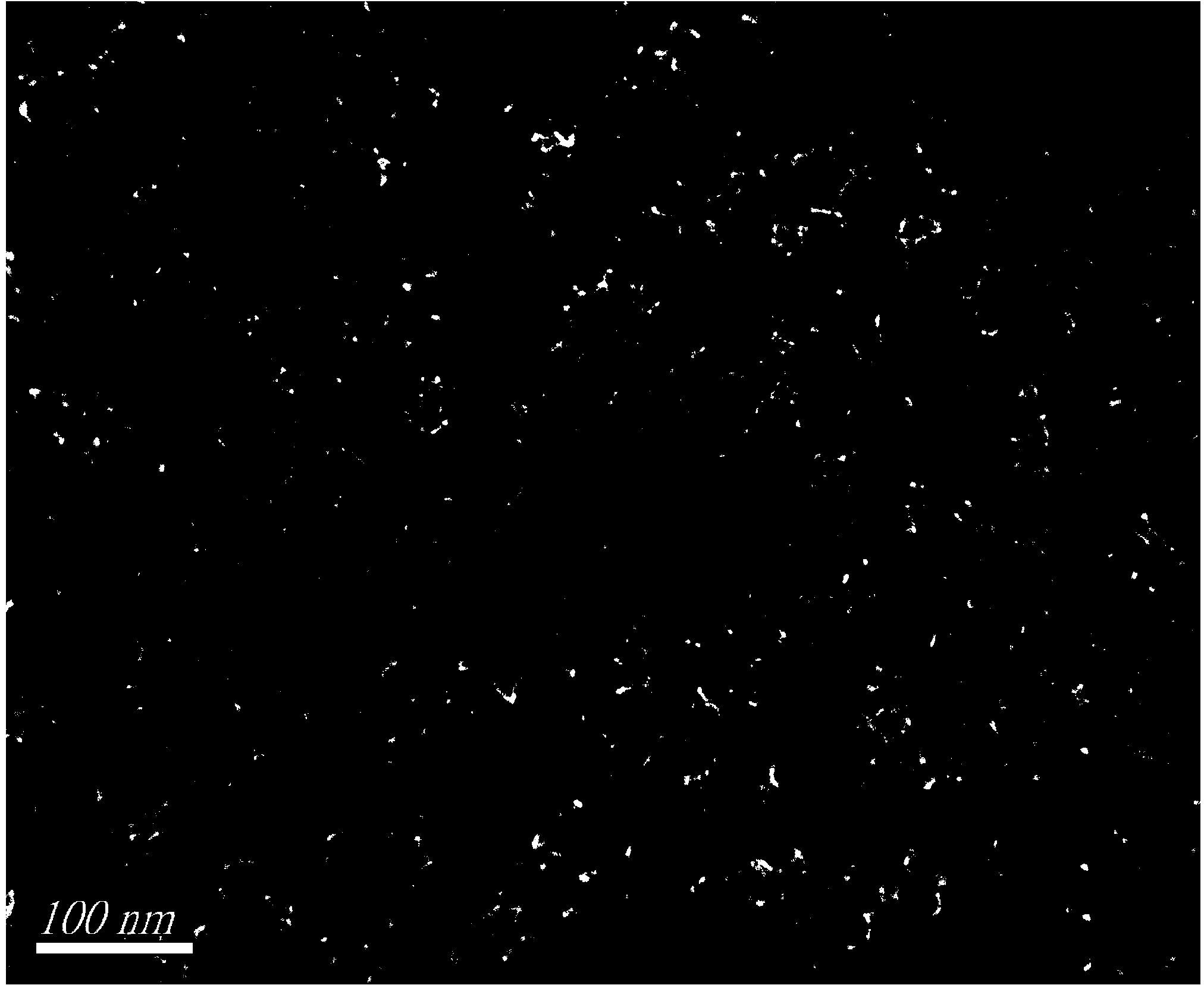

[0047] (1) Co-precipitation method to synthesize oleic acid-modified Fe3O4 magnetic nanoparticles

[0048] ferric chloride hexahydrate (FeCl 3 ·6H 2 O) dissolved in deionized water, and stirred under ultrasonic conditions (power 200W) for 10 minutes to obtain a stable suspension A, in which FeCl 3 ·6H 2 The ratio of O to deionized water was 4.6:170 (g / mL). Ferrous chloride tetrahydrate (FeCl 2 4H 2 O) vigorous stirring at 800 rpm and nitrogen (N 2 ) under the protection of dissolved in the above-mentioned suspension A to form suspension B, wherein the control FeCl 2 4H 2 The ratio of O to suspension A was 1.6:170 (g / mL). After the temperature rises to 80°C, ammonia water (NH 3 ·H 2 O) (25%) was quickly added to the above suspension B under strong stirring at 800 rpm t...

Embodiment 2

[0067] The method for preparing a magnetic / core-shell molecular imprinted adsorbent by miniemulsion polymerization is carried out in the following steps:

[0068] (1) Co-precipitation method to synthesize oleic acid-modified Fe3O4 magnetic nanoparticles

[0069] ferric chloride hexahydrate (FeCl 3 ·6H 2 O) dissolved in deionized water, and stirred under ultrasonic conditions (power 200W) for 10 minutes to obtain a stable suspension A, in which FeCl 3 ·6H 2 The ratio of O to deionized water was 4.8:190 (g / mL). Ferrous chloride tetrahydrate (FeCl 2 4H 2 O) vigorous stirring at 800 rpm and nitrogen (N 2 ) under the protection of dissolved in the above-mentioned suspension A to form suspension B, wherein the control FeCl 2 4H 2The ratio of O to suspension A was 1.8:190 (g / mL). After the temperature rises to 80°C, ammonia water (NH 3 ·H 2 O) (25%) was quickly added to the above suspension B under strong stirring at 800 rpm to form a dark brown magnetic fluid C, in which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com