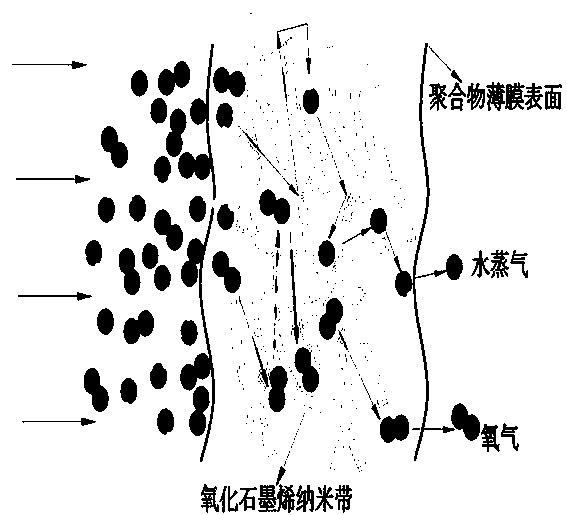

Oxidized graphene nano-ribbon/polymer composite film and preparation method thereof

A graphene nanoribbon and composite film technology, which is applied in the field of polymer composite film preparation, can solve the problems of unfavorable use, high preparation cost, and easy entanglement of graphene nanoribbons, and achieve low cost, simple preparation process, and excellent barrier The effect of performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation of graphene oxide nanoribbons comprises the following steps:

[0032] 1) Mix 20 ml of H with a mass fraction of 85.8% 3 PO 4 The solution was added to a 500 ml round bottom flask with a magnetic rotor, and then 200 ml concentrated H 2 SO 4 Join in the round bottom flask, stir under the rotating speed of 300r / min;

[0033] 2) Add 1 g of multi-walled carbon nanotubes to the solution in step 1), stir for 2 h, and then add 6 g of KMnO 4 Add slowly to the above mixture in 3 steps, and stir for another 20 min;

[0034] 3) Move the reaction system in step 2) to an oil bath at 55°C, stir and react at a speed of 300r / min for 2 h, let cool to room temperature, and then pour into a solution containing 5 ml H 2 o 2 Condensate in the ice-water mixture of 24 h, and this moment solution turns dark green, shows that reaction is complete;

[0035] 4) The solution in step 3) was ultrasonically dispersed at 100 W for 30 min, washed and filtered on a polytetrafluoroe...

Embodiment 1

[0041] The preparation of graphene oxide nanobelt / polymer composite film comprises the following steps:

[0042] 1) Dissolve 15 g of polyester thermoplastic polyurethane in 40 ml of N-N dimethylformamide, and swell for 12 hours in a blast drying oven at 80 °C;

[0043] 2) Dissolve 0.045 g of graphene oxide nanoribbons in 10 ml of N-N dimethylformamide, and 100 W ultrasonic dispersion for 20 min;

[0044] 3) Mix the polymer solution in step 1) and the ultrasonically dispersed graphene oxide nanoribbons in step 2) evenly, 100 W ultrasonically disperse for 1 hour, and then stir on a mechanical mixer for 3 hours to form a paste liquid;

[0045] 4) Pour the pasty liquid into a small volumetric flask with a straw, and then pump out the air in the pasty liquid on a suction filter until there are no air bubbles in the volumetric flask; place the glass plate on the film coater, and use a wet Coat a film with a thickness of 0.09mm on the film preparation device, and then place the glas...

Embodiment 2

[0047] The preparation of graphene oxide nanobelt / polymer composite film comprises the following steps:

[0048] 1) Dissolve 15 g of polyether thermoplastic polyurethane in 60 ml of tetrahydrofuran, and swell for 12 hours in an air-blast drying oven at 80 °C;

[0049] 2) Dissolve 0.075 g of graphene oxide nanoribbons in 10 ml of tetrahydrofuran, and 100 W ultrasonic dispersion for 20 min;

[0050] 3) Mix the polymer solution in step 1) and the ultrasonically dispersed graphene oxide nanoribbons in step 2) evenly, 100 W ultrasonically disperse for 3 h, and then stir on a mechanical mixer for 2 h to form a paste liquid;

[0051] 4) Pour the pasty liquid into a small volumetric flask with a straw, and then pump out the air in the pasty liquid on a suction filter until there are no air bubbles in the volumetric flask; place the glass plate on the film coater, and use a wet The film preparation device was coated with a film with a thickness of 0.09 mm, and then the glass plate was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com