Sulfur methanation resistant process for preparing substitute natural gas from coke-oven gas

A sulfur-resistant methanation technology that replaces natural gas. It is applied in the petroleum industry, gas fuel, and fuel. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

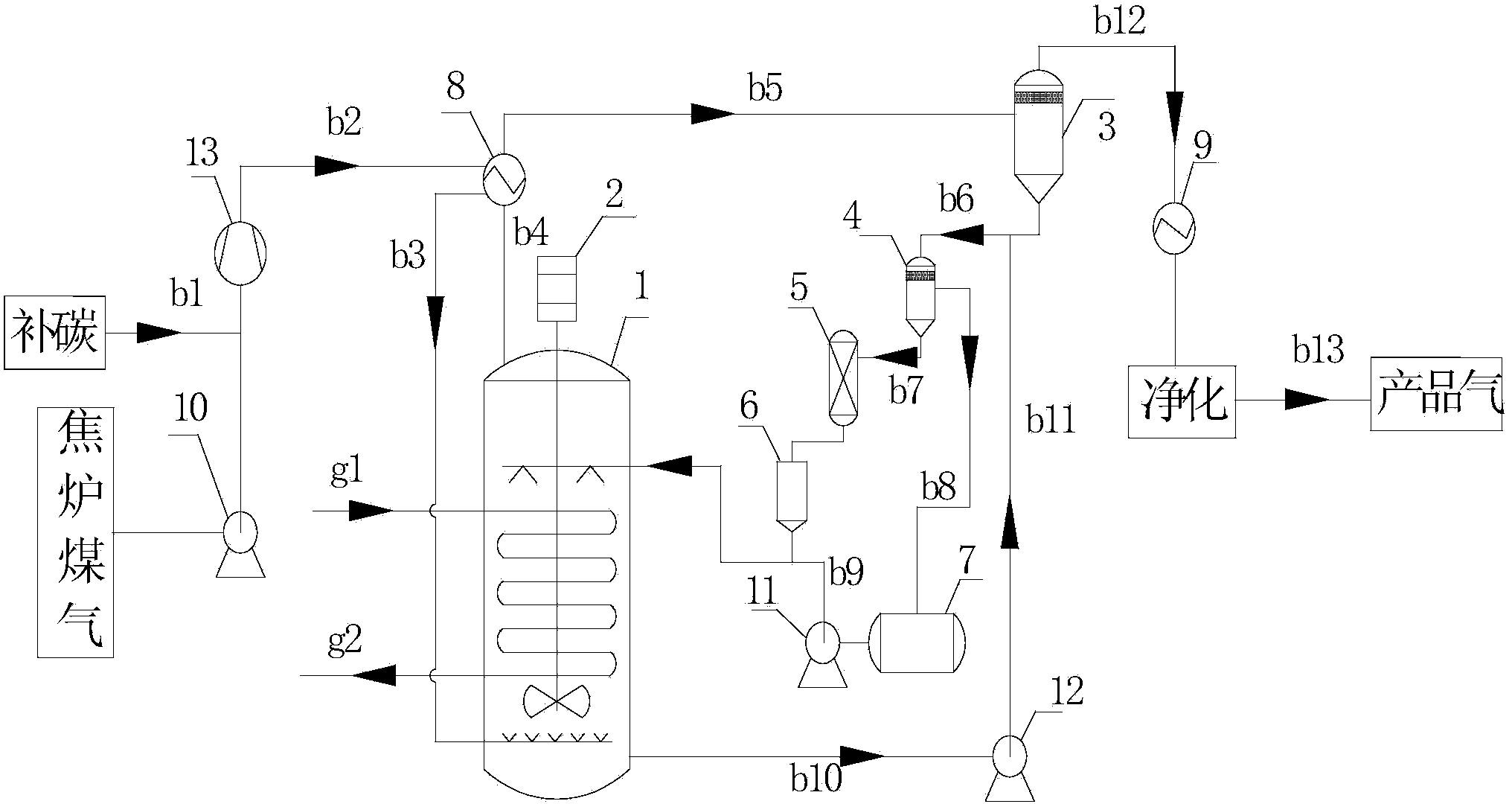

Method used

Image

Examples

Embodiment 1

[0048] Preparation of Sulfur-Resistant Methanation Catalyst for Slurry Bed Coke Oven Gas:

[0049] 60-80 mesh, specific surface area 150m 2 / g γ-Al 2 o 3 Calcined at 450°C for 5h, at a temperature of 35°C and a stirring speed of 120r / min, the Mo(NO 3 ) 3 ·5H 2 O, Ni(NO 3 ) 2 ·6H 2 O, γ-Al 2 o 3 According to the mass percentage of Mo: Ni: Al 25%: 30%: 45% equal volume impregnation and stirring for 8 hours, after standing for 4 hours, evaporate at 80°C until viscous, then put it in an oven for 12 hours and dry at 110°C, and then grind to 60-80 mesh Place in a muffle furnace and bake at 550°C for 6 hours to obtain a precursor; the volume composition is 25%H 2 and 75%N 2 , in an atmosphere with a flow rate of 80mL / min, using a two-stage temperature program, first raising the temperature to 350 °C at 5 °C / min, and then raising the temperature to 550 °C at 3 °C / min for 6 hours to obtain a mass percentage of Mo:Ni:Al of 25 %: 30%: 45% Mo-Ni-Al slurry bed coke oven gas sul...

Embodiment 2

[0056] Preparation of Sulfur-Resistant Methanation Catalyst for Slurry Bed Coke Oven Gas:

[0057] Calcinate γ-Al2O3 with 160-200 mesh and specific surface area of 280m2 / g at 550°C for 7h, and then mix Mo(NO3)3·5H2O, Co(NO3)2·6H2O at 30°C and stirring speed of 200r / min , Ni(NO3)2·6H2O, γ-Al2O3 according to the mass percentage of Mo: Co: Ni: Al 20%: 10%: 35%: 35% equal volume impregnation and stirring for 24h, after standing for 10h, evaporate at 70°C to viscous , and then placed in an oven for 24 hours at 100°C, and then ground to 160-200 mesh, placed in a muffle furnace and roasted at 500°C for 8 hours to obtain a precursor; the volume composition is 15% H2 and 85% N2, and the flow rate is 120mL / In the atmosphere of min, adopt two-stage temperature program, first raise the temperature to 350°C at 5°C / min, and then raise the temperature to 600°C at 2°C / min for constant temperature reduction for 12h to obtain the mass percentage of Mo:Co:Ni:Al 20%:10 %: 35%: 35% Mo-Co-Ni-Al...

Embodiment 3

[0064] Preparation of Sulfur-Resistant Methanation Catalyst for Slurry Bed Coke Oven Gas:

[0065] Calcinate SiO2 with 80-100 mesh and specific surface area of 180m2 / g at 450°C for 4h. Under the conditions of temperature 25°C and stirring speed of 120r / min, Ni(NO3)2·6H2O, Co(NO3)2·6H2O, SiO2 According to the mass percentage of Ni: Co: Si 30%: 20%: 50% equal volume impregnation and stirring for 8 hours, after standing for 4 hours, evaporate to viscous at 80°C, then put it in an oven to dry at 110°C for 12 hours, and then grind to 80-100 mesh Place in a muffle furnace and roast at 450°C for 4 hours to prepare the precursor; in an atmosphere with a volume composition of 20% H2 and 80% N2 and a flow rate of 100mL / min, two-stage temperature programming is adopted, first at 4°C / min Raise the temperature to 350°C, then raise the temperature to 550°C at 2°C / min for constant temperature reduction for 6 hours to obtain Ni-Co-Si slurry bed coke oven gas sulfur-resistant methane with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com