Device and method for preparing high-purity tetrapropylammonium hydroxide and co-producing bromine through electrolysis

A technology of tetrapropylammonium hydroxide and tetrapropylammonium bromide, which is applied in the field of preparation of bromine co-produced by tetrapropylammonium hydroxide, can solve the problem of difficult large-scale safe production, difficult recovery of by-product bromide, The yield of finished products is not high, so as to achieve the effect of easy automatic control, environmental protection and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

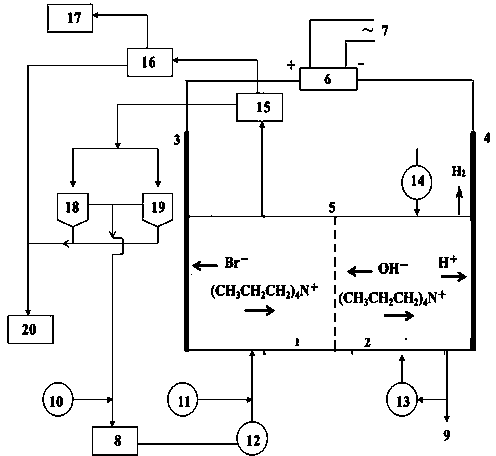

Method used

Image

Examples

Embodiment 1

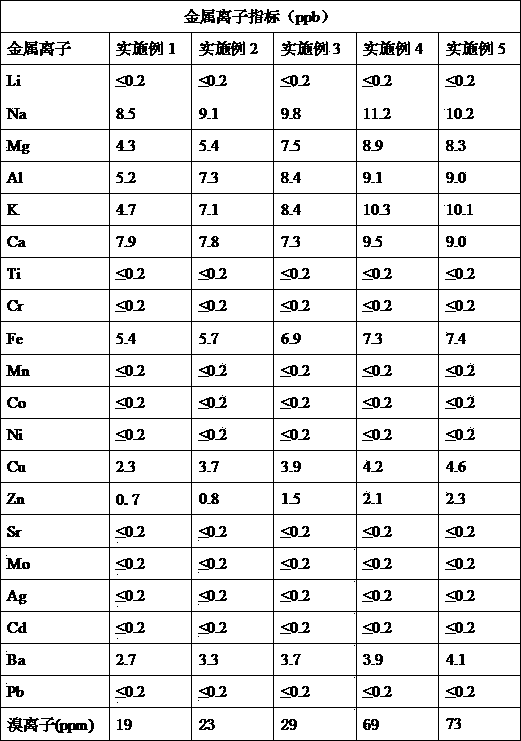

[0026] Under the reaction condition of 60 °C, a tetrapropylammonium bromide solution with a mass concentration of 45% was added to the anode chamber 1, and the current density was 600 A / m 2 , after the electrolysis reaction, the tetrapropylammonium hydroxide with a mass concentration of 25% in the cathode chamber 2 was obtained. The mass concentration of each metal ion in tetrapropylammonium hydroxide is less than 20 ppb, and the mass concentration of bromide ion is less than 100 ppm (see Table 1); the current efficiency is 52%, and the product conversion rate is 98.2%.

Embodiment 2

[0028] Under the reaction condition of 70 °C, a solution of tetrapropylammonium bromide with a mass concentration of 55% was added to the anode chamber 1, and 700 A / m 2 The current density, after the electrolysis reaction, obtains the tetrapropyl ammonium hydroxide that mass concentration is 30% in the cathode chamber 2. The mass concentration of each metal ion in tetrapropylammonium hydroxide is less than 20 ppb, and the mass concentration of bromide ion is less than 100 ppm (see Table 1); the current efficiency is 61%, and the product conversion rate is 98.3%.

Embodiment 3

[0030] Under the reaction condition of 75 °C, a tetraethylammonium bicarbonate solution with a mass concentration of 55% was added to the anode chamber 1, and the current density was 800 A / m 2 , after the electrolysis reaction, the tetrapropylammonium hydroxide with a mass concentration of 20% in the cathode chamber 2 was obtained. The mass concentration of each metal ion in tetrapropylammonium hydroxide is less than 20 ppb, and the mass concentration of bromide ion is less than 100 ppm (see Table 1); the current efficiency is 65%, and the product conversion rate is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com