Composite electrode material vanadium trioxide or carbon for super capacitor and preparation method thereof

A technology for supercapacitors and composite electrodes, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as poor cycle performance, improve specific capacity, improve bulk conductivity, and be suitable for large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

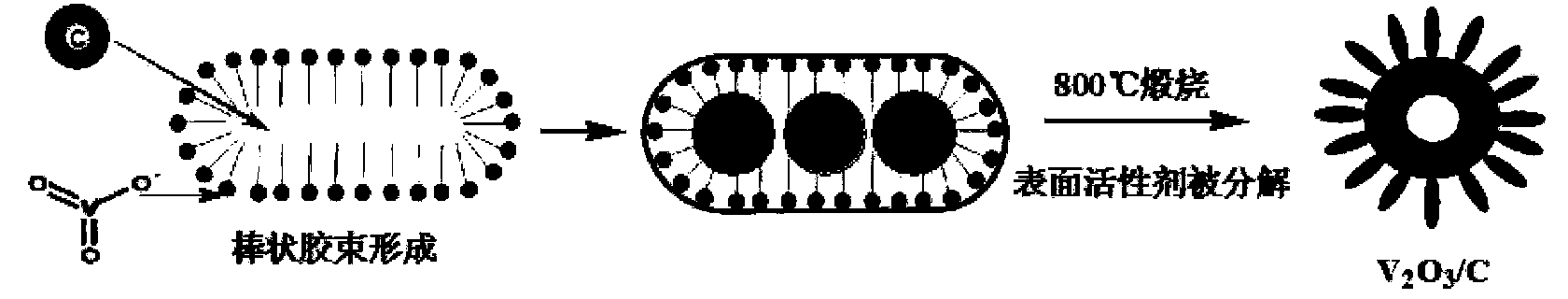

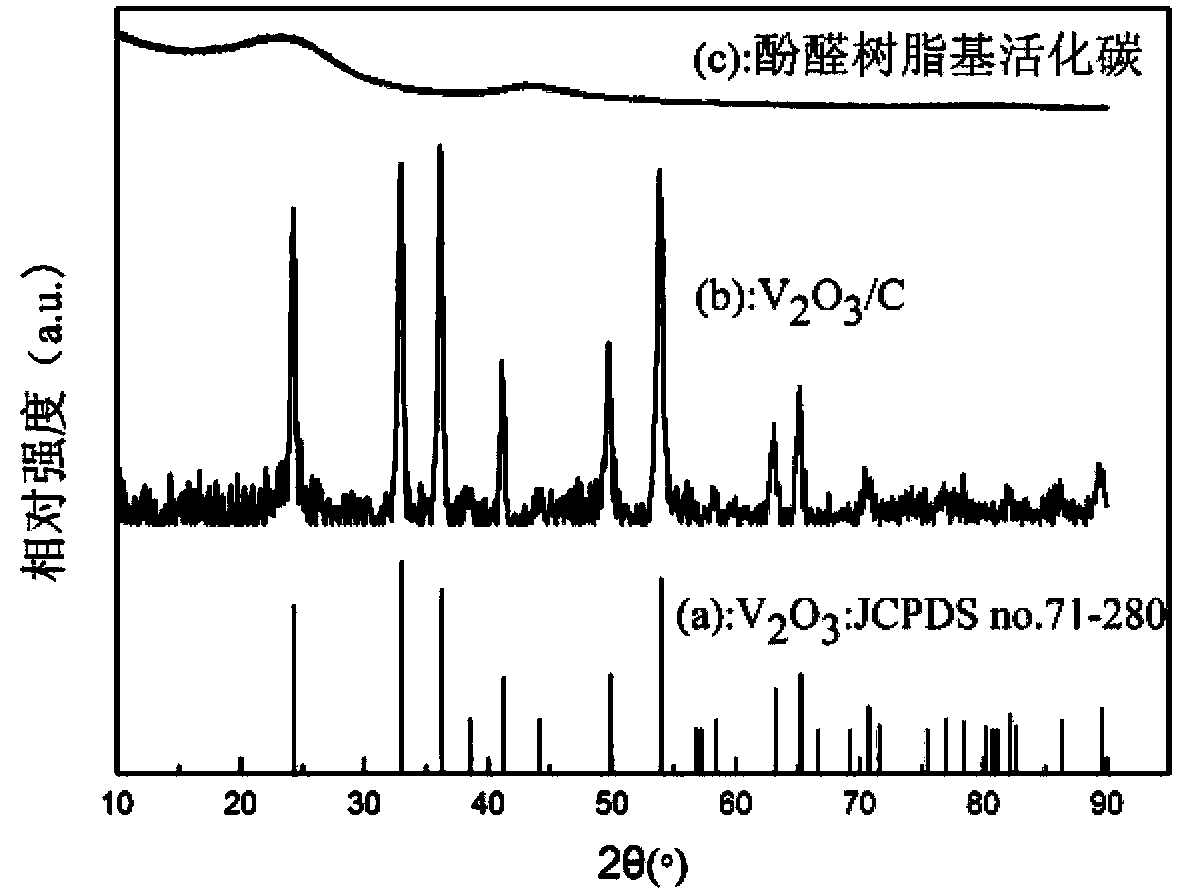

[0020] In an exemplary embodiment of the present invention, the composite electrode material V 2 o 3 The preparation method of nanosheet / C comprises the following steps:

[0021] A. Preparation of activated carbon source

[0022] The carbon source is obtained by carbonizing the phenolic resin at high temperature under the protection of an inert gas (for example, argon). For example, the temperature of high temperature carbonization may be 800-1000° C., preferably 850-920° C., and the carbonization time is 3-4 hours.

[0023] Subsequently, with 3~6mol / L HNO 3 The carbon source is activated by the solution at a water bath temperature of 70-100° C. (preferably 80-90° C.), then centrifuged and washed with distilled water (for example, to a pH of 7), and then dried. For example, the drying temperature can be 60-90°C, preferably 75-84°C, to obtain the activated carbon source.

[0024] Here, in the activation step, nitric acid activation can remove some impurities on the surface...

example 1

[0055] (1) Carbonize the phenolic resin in a vacuum tube furnace at 800°C for 3h, and then use 3mol / L HNO 3 Condensate and reflux at 100°C for 6 hours to fully activate, cool, centrifuge, wash, and dry at 80°C to obtain a carbon source for use;

[0056] (2) Weigh 4g CTAB and add it to 20mL deionized water, heat it in a 70°C water bath to dissolve;

[0057] (3) Weigh 0.512g of carbon and add it to 20ml of CTAB micellar solution with a concentration of 0.2g / ml and ultrasonically shake for 30min to fully disperse it;

[0058] (4) Weigh 2.42g NH 4 VO 3 Stir to dissolve it in 100mL, 70°C deionized water;

[0059] (5) Heat the mixed solution in (3) and (4) in a water bath at 70°C for 3 hours with magnetic stirring;

[0060] (6) Calcining the lower layer solid reacted in (5) under the protection of argon at 800°C for 3 hours to obtain V 2 o 3 Nanosheet / C composite electrode materials. will prepare the V 2 o 3 The nanosheet / C composite electrode material sample, acetylene black...

example 2

[0063] (1) Carbonize the phenolic resin in a vacuum tube furnace at 800°C for 3h, then use 3mol / L HNO 3 Condensate and reflux at 100°C for 6 hours to fully activate, cool, centrifuge, wash, and dry at 80°C to obtain a carbon source for use;

[0064] (2) Weigh 6g of CTAB and add it to 20mL deionized water, heat it in a water bath at 70°C to dissolve;

[0065] (3) Weigh 1.157g of carbon and add it to 20ml of CTAB micellar solution with a concentration of 0.3g / ml and ultrasonically shake for 30min to fully disperse it;

[0066] (4) Weigh 2.42g NH 4 VO 3 Stir to dissolve it in 100mL, 70°C deionized water;

[0067] (5) Heat the mixed solution in (3) and (4) in a water bath at 70°C for 3 hours with magnetic stirring;

[0068] (6) Calcining the lower layer solid reacted in (5) under the protection of argon at 800°C for 3 hours to obtain V 2 o 3 Nanosheet / C composite electrode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com