Method for preparing nickel lithium manganate by using waste lithium manganate battery

A technology of old lithium manganese oxide and nickel manganese oxide lithium, which is applied in the field of recycling waste lithium manganese oxide batteries, to achieve the effects of easy control, large-scale application, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

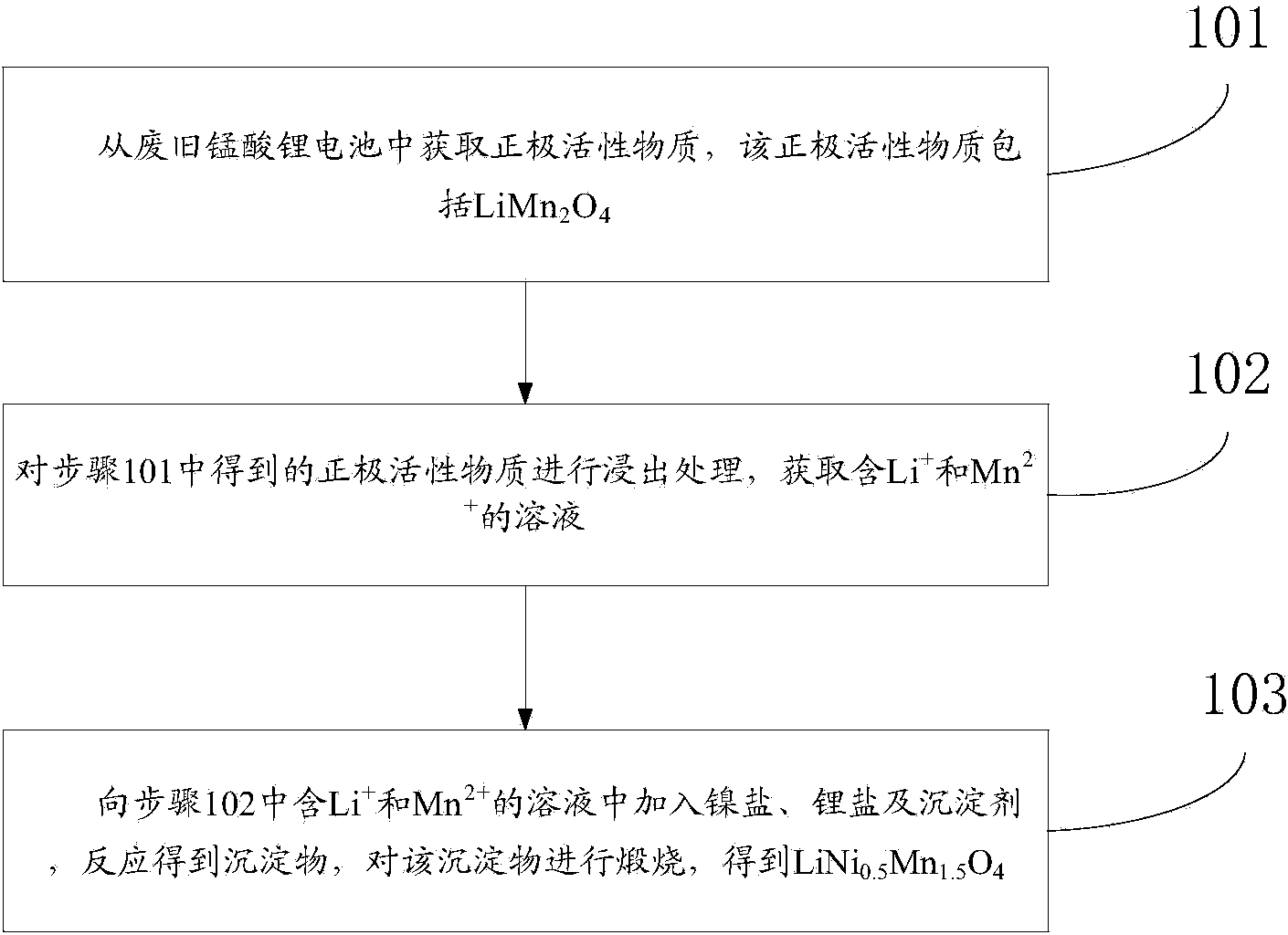

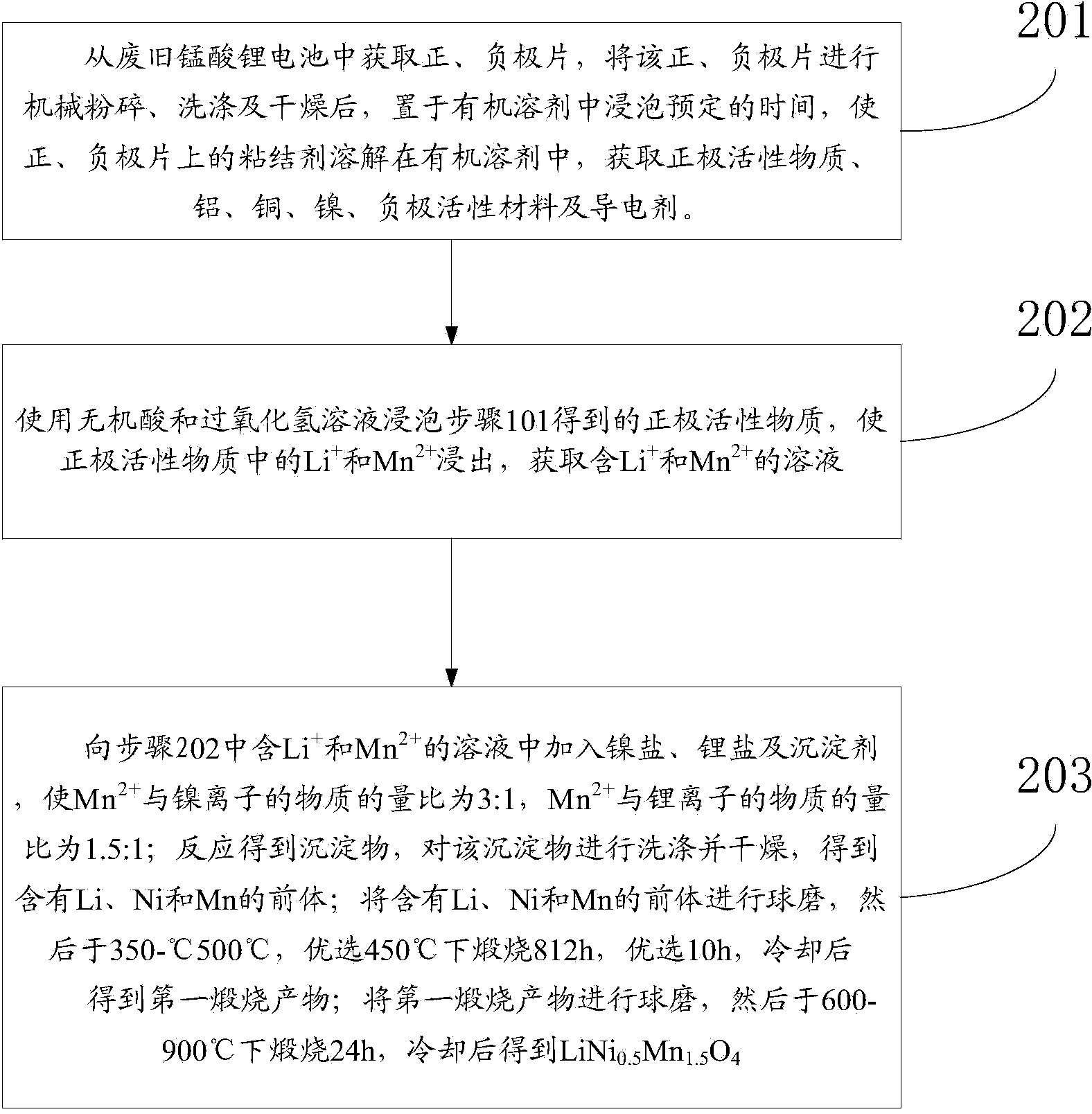

Method used

Image

Examples

Embodiment 1

[0076] Discharge treatment, mechanical cutting, classification and dismantling of waste lithium manganate batteries are carried out sequentially to obtain battery case, diaphragm and positive and negative electrodes. Separate and recycle battery casings and separators. After the obtained positive and negative plates are mechanically crushed, washed and dried, they are soaked in NMP for a predetermined time, so that the binder PVDF on the positive and negative plates is dissolved in NMP, that is, the active material falls off from the current collector, and after Filter to obtain current collector and filter residue.

[0077] After washing and drying the obtained filter residue several times, take 1 g for use. Ball mill the filter residue, and then add 19.6 mL of H2SO with a concentration of 2 mol / L to the filter residue at 40°C 4 with 0.4 mL of 30 wt% H 2 o 2 , with a solid-to-liquid ratio of 50g / L, fully reacted under stirring conditions, and obtained filtrate and conduct...

Embodiment 2

[0080] Discharge treatment, mechanical cutting, classification and dismantling of waste lithium manganate batteries are carried out sequentially to obtain battery case, diaphragm and positive and negative electrodes. Separate and recycle battery casings and separators. After the obtained positive and negative plates are mechanically crushed, washed and dried, they are soaked in NMP for a predetermined time, so that the binder PVDF on the positive and negative plates is dissolved in NMP, that is, the active material falls off from the current collector, and after Filter to obtain current collector and filter residue.

[0081] After washing and drying the obtained filter residue several times, take 1 g for use. The filter residue was ball milled, and then 19.6 mL of 0.1 mol / L H 2 SO 4 with 4 mL of 30 wt% H 2 o 2 , the solid-to-liquid ratio is 10g / L, fully react under stirring conditions, and obtain the filtrate and conductive agent after filtration. The conductive agent wa...

Embodiment 3

[0084] Discharge treatment, mechanical cutting, classification and dismantling of waste lithium manganate batteries are carried out sequentially to obtain battery case, diaphragm and positive and negative electrodes. Separate and recycle battery casings and separators. After mechanically pulverizing, washing and drying the obtained positive and negative plates, soak them in N-N dimethylacetamide for a predetermined time, so that the binder PVDF on the positive and negative plates is dissolved in N-N dimethylacetamide , that is, the active substance falls off from the current collector and is filtered to obtain the current collector and filter residue.

[0085] After washing and drying the obtained filter residue several times, take 1 g for use. The filter residue was ball-milled, and then at 60°C, 48 mL of 0.7 mol / L H 2 SO 4 with 2 mL of 30 wt% H 2 o 2 , with a solid-to-liquid ratio of 20g / L, fully reacted under stirring conditions, and obtained filtrate and conductive ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com