A kind of hairy grape collagen polypeptide ca yogurt

A technology of collagen peptides and hairy grapes, which is applied in milk preparations, dairy products, applications, etc., can solve problems such as defects, and achieve the effects of saving energy and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

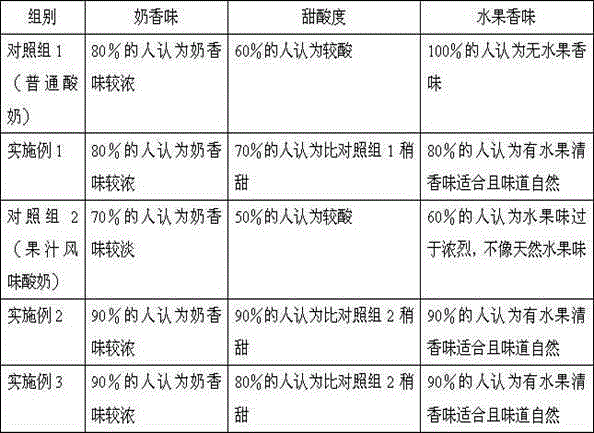

Examples

Embodiment 1

[0054] Preparation of sterilized grape juice:

[0055] Rinse the selected ripe grape fruit with flowing water to remove the surface sediment, take it out and dry it, pick the fruit stalk, and place it at 5°C for 1 hour; take out the fruit damaged by the low temperature, and put it Transfer to an environment of 30° C. for 1 hour; then repeat the above steps 10 times to obtain grape fruit after variable temperature treatment.

[0056] Put the grape fruit after the temperature-changing treatment into the press, squeeze the juice out with a pressure of 10MPa, and pass through a centrifuge through a 1×10 3 Centrifuge at rpm for 30 minutes, filter through a 0.3mm sieve to remove suspended solids in the juice, place the temperature of the juice at 15±3°C, add pectinase EX-V to clarify the juice at a ratio of 1g / 100kg grape fruit, and pass through After filtering through a fine filter with a pore size of 20 μm, it is degassed by a vacuum degasser at 0.5 MPa at 85°C, then heated at 60...

Embodiment 2

[0064] (1) Preparation of sterilized raw grape juice:

[0065] Rinse the selected ripe grape fruit with flowing water to remove the surface sediment, take it out and dry it, pick the fruit stem, and place it at 18°C for 2 hours; take out the fruit damaged by the low temperature, and put it Transfer to an environment of 45° C. for 1 hour; then repeat the above steps 20 times to obtain grape fruit after variable temperature treatment.

[0066] Put the grape fruit after the temperature-changing treatment into the press, squeeze the juice out with a pressure of 20MPa, squeeze the juice out, and pass through a centrifuge through a 1×10 3 Centrifuge at rpm for 40 minutes, filter through a 0.5mm sieve to remove suspended solids in the juice, place the temperature of the juice at 10±3°C, add pectinase EX to clarify the juice at a ratio of 3g / 100kg of grape fruit, and pass through a pore size of After filtering through a 20μm fine filter, degassing through a vacuum degasser at 1MPa,...

Embodiment 3

[0074] (1) Preparation of sterilized raw grape juice:

[0075] Rinse the selected ripe grape fruit with flowing water to remove the surface sediment, take it out and dry it, pick the fruit stalk, and place it at 4°C for 1 hour; take out the fruit damaged by the low temperature, and put it Transfer to an environment of 45° C. for 1 hour; then repeat the above steps 15 times to obtain grape fruit after variable temperature treatment.

[0076]Put the grape fruit after the temperature-changing treatment into the press, squeeze the juice out with a pressure of 15MPa, squeeze the juice out, and pass through a centrifuge through a 1×10 3 Centrifuge at rpm for 30 minutes, filter through a 0.3mm sieve to remove suspended solids in the juice, place the temperature of the juice at 10±3°C, add pectinase EX at a ratio of 3g / 100kg of grape fruit to clarify the juice, and pass through a pore size of After filtering through a 20μm fine filter, degassing through a vacuum degasser at 1MPa, 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com