A green liquor dissolution tank exhaust recovery device

An exhaust gas recovery and dissolving tank technology, which is applied in the fields of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as alkali dust emission, and achieve the effects of reducing gas emission, reducing the degree of corrosion, and running stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

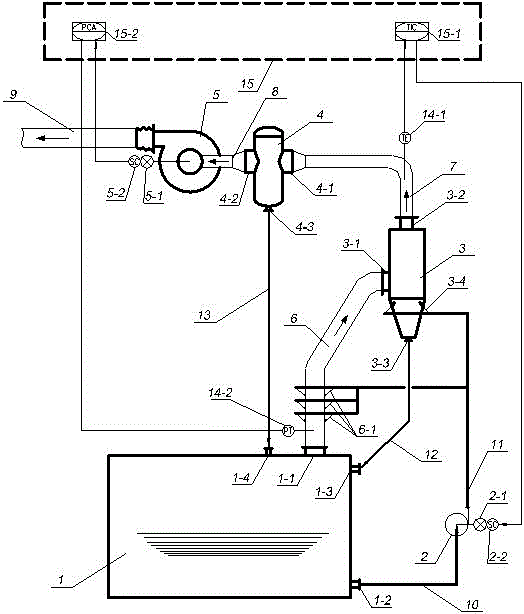

[0062] The present invention will be further described according to accompanying drawing:

[0063] A green liquor dissolving tank exhaust recovery device, which includes: green liquor dissolving tank 1, spray water pump 2, cyclone separator 3, mist separator 4, exhaust fan 5, dissolving tank exhaust pipe 6, cyclone Separator exhaust pipe 7, mist separator exhaust pipe 8, induced fan exhaust pipe 9, spray water pump inlet pipe 10, spray water pipe 11, green liquid pipe 12, condensate water 13, temperature sensor 14-1, Pressure transmitter 14-2, PLC control system 15. Its connection relationship is: the green liquid dissolving tank 1 is located on the ground (±0.00m) of the first floor, and the green liquid dissolving tank 1 is provided with a first dissolving tank exhaust port 1-1, a second green liquid outlet 1-2, The third green liquid inlet 1-3, the fourth condensed water inlet 1-4; the front exhaust port 1-1 of the first dissolution tank on the upper part of the green liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com