A kind of styrene-acrylic emulsion with excellent freeze-thaw stability and its preparation method and application

A technology of freeze-thaw stability and styrene-acrylic emulsion, applied in latex paint, etc., can solve the problems of increasing the VOC content of paint products, poor freeze-thaw stability, and poor freeze-thaw resistance, so as to promote freeze-thaw stability and stabilize the polymerization process , the effect of high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

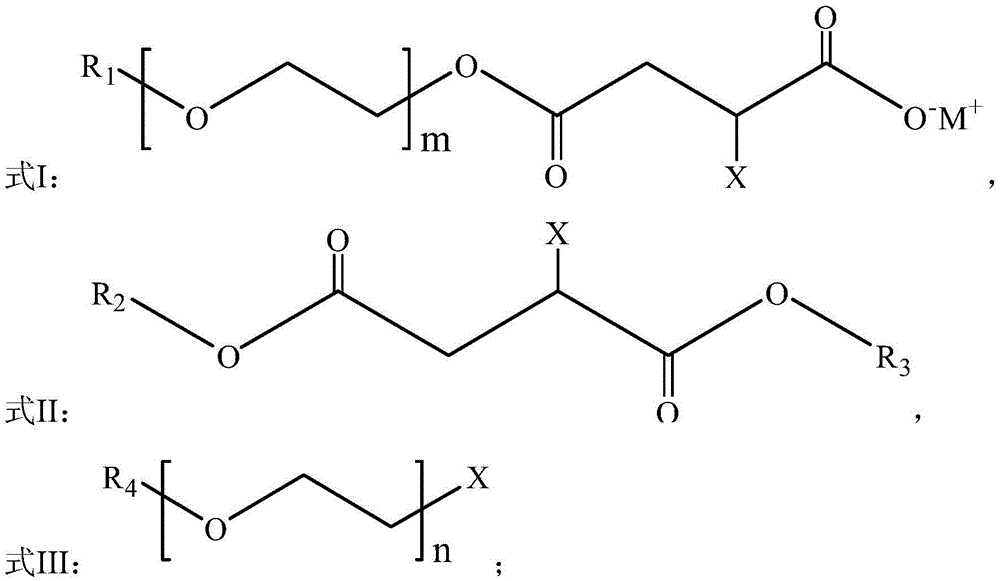

Method used

Image

Examples

Embodiment 1

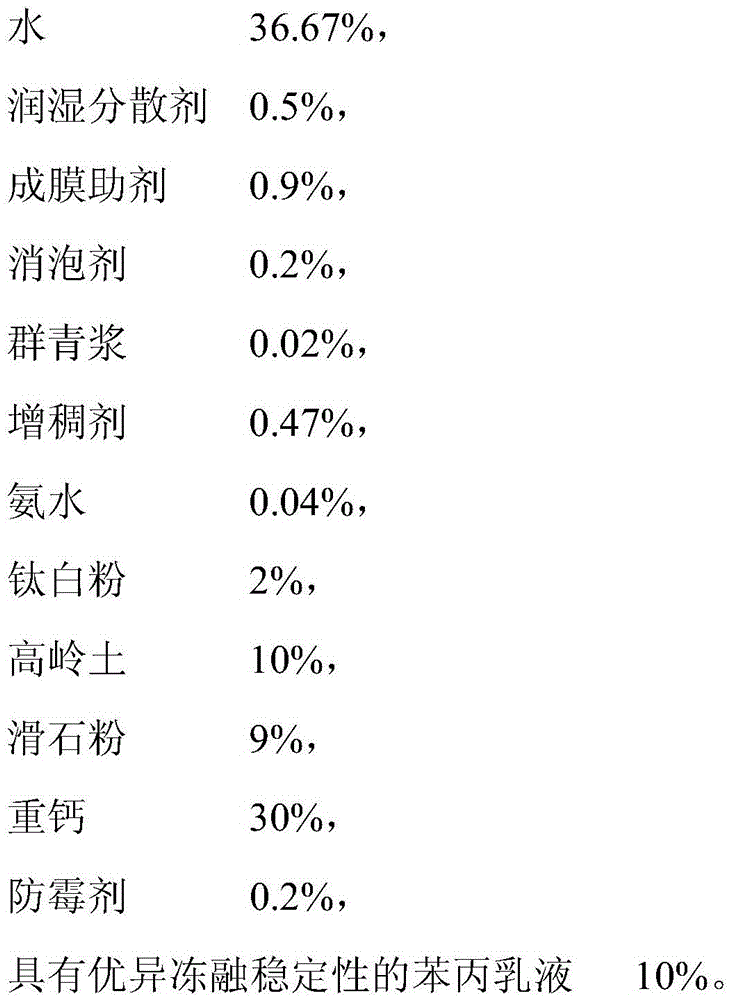

[0037] A styrene-acrylic emulsion with excellent freeze-thaw stability. The styrene-acrylic emulsion is prepared by a core-shell emulsion polymerization method. The raw material components and amounts used are as follows:

[0038] Polymerization main monomer: 60g styrene (St), 40g butyl acrylate (BA);

[0039] Other materials: 2g methacrylic acid (MAA), 0.2g functional polymerized monomer (COPS-2), 0.75g anion-nonionic composite emulsifier (KL-70), 0.5g ammonium persulfate (APS), 0.4g carbonic acid Sodium hydrogen, 100g deionized water;

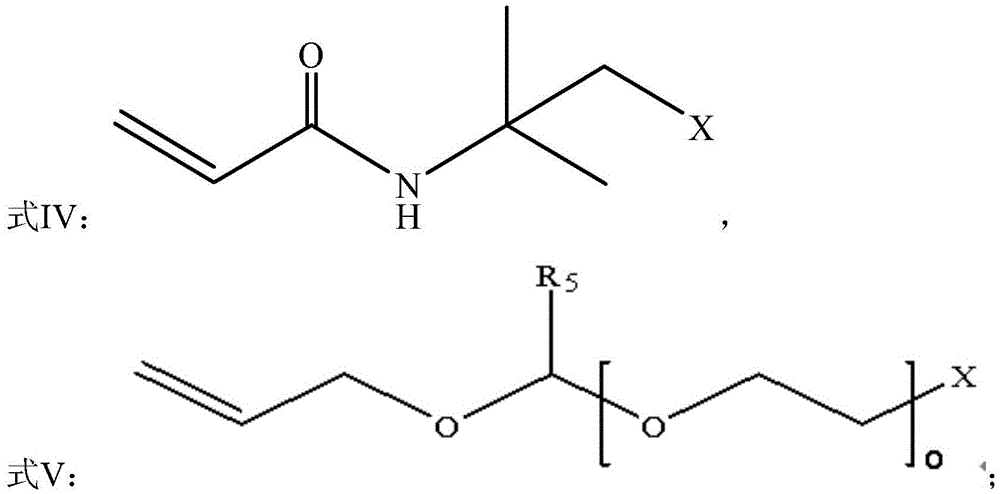

[0040] Among them, the functional polymerized monomer (COPS-2) is a functional polymerized monomer conforming to the general structural formula IV, and the specific structural formula is:

[0041] Anion-nonionic composite emulsifier (KL-70) is an anion-nonionic composite emulsifier conforming to the general structural formula III. The specific structural formula is:

[0042] The preparation method of the styrene-acrylic emulsion with excellent freez...

Embodiment 2

[0048] A styrene-acrylic emulsion with excellent freeze-thaw stability. The styrene-acrylic emulsion is prepared by a core-shell emulsion polymerization method. The raw material components and amounts used are as follows:

[0049] Polymerization main monomer: 60g styrene (St), 40g butyl acrylate (BA);

[0050] Other materials: 2g methacrylic acid (MAA), 0.6g functional polymerized monomer (COPS-2), 0.75g anion-nonionic composite emulsifier (KL-70), 0.5g ammonium persulfate (APS), 0.4g Sodium bicarbonate, 100g deionized water;

[0051] Wherein, the functional polymerized monomer (COPS-2) is the same functional polymerized monomer as described in Example 1;

[0052] The anionic-nonionic composite emulsifier (KL-70) is the same anionic-nonionic composite emulsifier as described in Example 1.

[0053] The preparation method of the styrene-acrylic emulsion with excellent freeze-thaw stability is as follows:

[0054] (1) Add sodium bicarbonate, anionic-nonionic composite emulsifier (KL-70), 2...

Embodiment 3

[0059] A styrene-acrylic emulsion with excellent freeze-thaw stability. The styrene-acrylic emulsion is prepared by a core-shell emulsion polymerization method. The raw material components and amounts used are as follows:

[0060] Polymerization main monomer: 60g styrene (St), 40g butyl acrylate (BA);

[0061] Other materials: 2g methacrylic acid (MAA), 1g functional polymerized monomer (COPS-2), 0.75g anion-nonionic composite emulsifier (KL-70), 0.5g ammonium persulfate (APS), 0.4g carbonic acid Sodium hydrogen, 100g deionized water;

[0062] Wherein, the functional polymerized monomer (COPS-2) is the same functional polymerized monomer as described in Example 1;

[0063] The anionic-nonionic composite emulsifier (KL-70) is the same anionic-nonionic composite emulsifier as described in Example 1.

[0064] The preparation method of the styrene-acrylic emulsion with excellent freeze-thaw stability is as follows:

[0065] (1) Add sodium bicarbonate, anionic-nonionic composite emulsifier (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com