A Method for Detecting Etched Sidewall Roughness Using Capacitance Change

A technology of sidewall roughness and capacitance change, applied in the field of ion etching technology, can solve the influence of the electrical performance of devices that cannot directly reflect the sidewall roughness, cannot accurately predict the sidewall roughness, and is difficult to change the sidewall roughness, etc. problem, to avoid electrical fatigue, easy to operate, to achieve the effect of simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

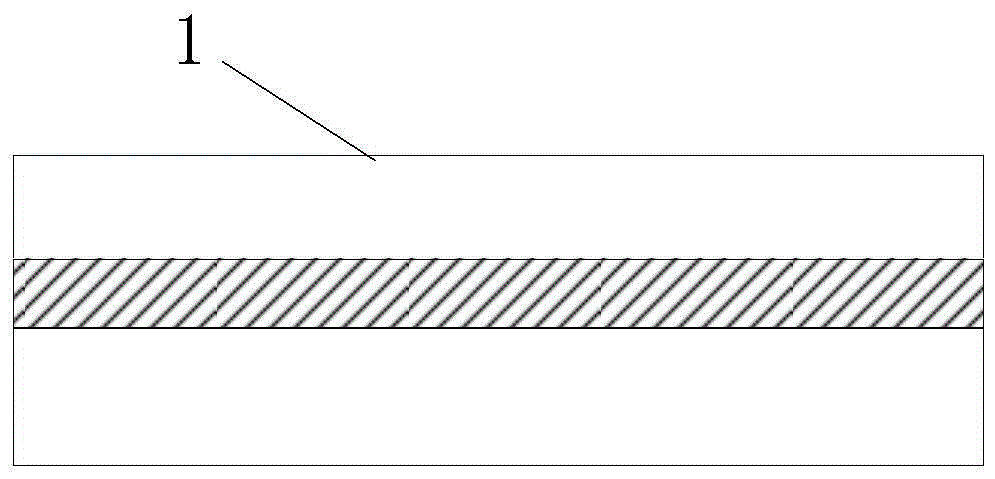

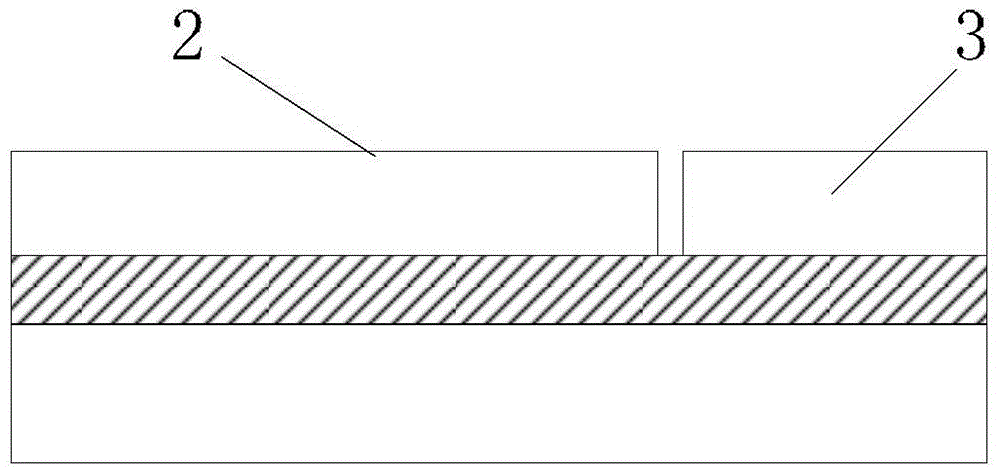

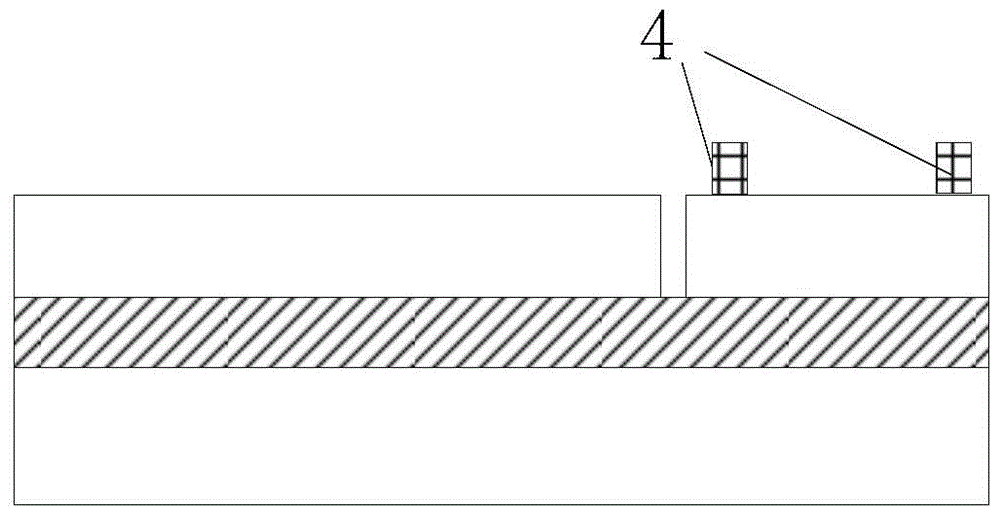

[0040] The method for detecting the roughness of the etched side wall by using the capacitance change in this embodiment is specifically implemented as follows: Figure 1(a) ~ Figure 1(g) As shown, the specific description is as follows:

[0041] 1. Preparation: SOI substrate 1 is used as the substrate of the chip, as shown in FIG. 1( a ).

[0042] 2. Use MEMS process photolithography on the substrate to define the detection area 3, and use the etching process to isolate the detection area 3 and the functional area 2, including: DRIE Si As shown in Figure 1(b).

[0043] The etching depth value is the thickness of the silicon layer on the front side of the SOI silicon wafer, and the front side silicon layer is etched through the etching process to realize the electrical insulation between the detection area 3 and the functional area 2 .

[0044] That is to say, in the present invention, the functional area and the detection area of the device are isolated by the buried oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com