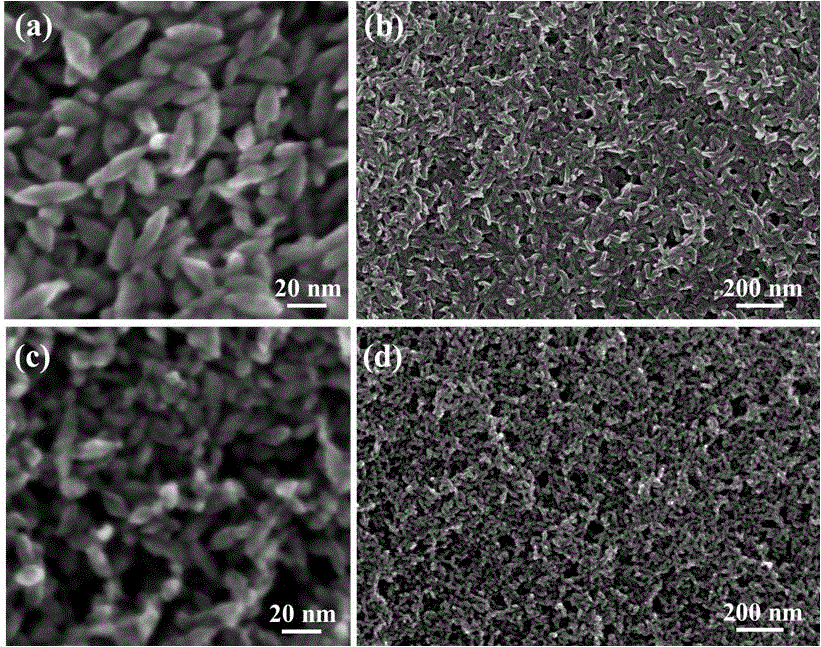

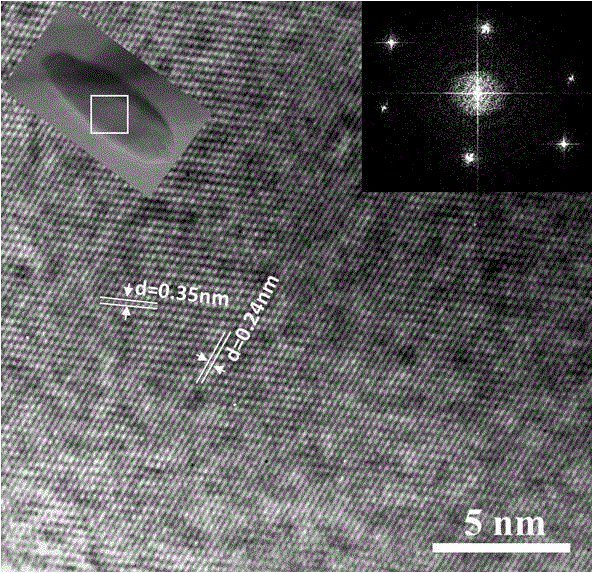

Preparation method for {100} crystal plane anatase TiO2 nano-particles

A technology of anatase phase and nanoparticle, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of few reports on the synthesis of nanoparticle, and achieve good dispersion and optical properties. High catalytic efficiency and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Under the condition of stirring, 2.5 g of titanium sulfate was dispersed and dissolved in 100 ml of deionized water. Slowly add tetramethylammonium hydroxide with a concentration of 0.1 moles per liter to the above solution until the solution is neutral (pH value is about 7), so that titanium sulfate is gradually hydrolyzed to form hydrated TiO 2 precipitation. hydrated TiO 2 Ultrasonic dispersion of precipitation, washing with deionized water several times, and centrifugation to obtain high-purity (purity above 97%) hydrated TiO 2 precipitation. Next, prepare 200 milliliters of hydrogen peroxide solution with a hydrogen peroxide volume fraction of 2%, and add dilute ammonia water to adjust it to form an alkaline hydrogen peroxide solution with a pH value of 10.5. Subsequently, the above-mentioned washed high-purity hydrated TiO 2 The precipitate was ultrasonically dispersed in the above-mentioned alkaline hydrogen peroxide solution with a pH value of 10.5 and a hyd...

Embodiment 2

[0048] Under the condition of stirring, 2.5 g of titanium sulfate was dispersed and dissolved in 100 ml of deionized water. Slowly add tetramethylammonium hydroxide with a concentration of 0.1 moles per liter to the above solution until the solution is neutral (pH value is about 7), so that titanium sulfate is gradually hydrolyzed to form hydrated TiO 2 precipitation. hydrated TiO 2 Ultrasonic dispersion of precipitation, washing with deionized water several times to obtain high-purity hydrated TiO 2 Precipitation and centrifugation to obtain high-purity hydrated TiO 2 precipitation. Next, prepare 200 milliliters of hydrogen peroxide solution with a hydrogen peroxide volume fraction of 2%, and add dilute ammonia to adjust it to form an alkaline hydrogen peroxide solution with a pH value of 8.5. Subsequently, the hydrated TiO with a purity of more than 97% after the above washing 2 The precipitate was ultrasonically dispersed in the above-mentioned alkaline hydrogen peroxi...

Embodiment 3

[0050] Under the condition of stirring, 5 g of titanium sulfate was dispersed and dissolved in 100 ml of deionized water. Slowly add ammonia water with a concentration of 0.2 moles per liter to the above solution until the solution is neutral (pH value is about 7), so that titanium sulfate is gradually hydrolyzed to form hydrated TiO 2 precipitation. hydrated TiO 2 Precipitation ultrasonic dispersion, washed with deionized water several times to obtain hydrated TiO with a purity of more than 97% 2 Precipitation, centrifugation. Next, prepare 200 milliliters of hydrogen peroxide solution with a hydrogen peroxide volume fraction of 5%, and add dilute tetramethylammonium hydroxide to adjust it to an alkaline hydrogen peroxide solution with a pH value of 9. Subsequently, the hydrated TiO with a purity of more than 97% after washing 2 The precipitate was stirred and dispersed in the above alkaline hydrogen peroxide solution with a pH value of 9 and a volume fraction of hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com