Technology for production of semicoke from powdery long flame coal

A production process and technology of long-flame coal, which is applied in coking ovens, petroleum industry, special forms of dry distillation, etc., can solve the problems of poor air permeability of powdery long-flame coal, backlog of funds, low efficiency, etc., and achieve mechanical strength enhancement, The effect of increasing transportation capacity and expanding production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

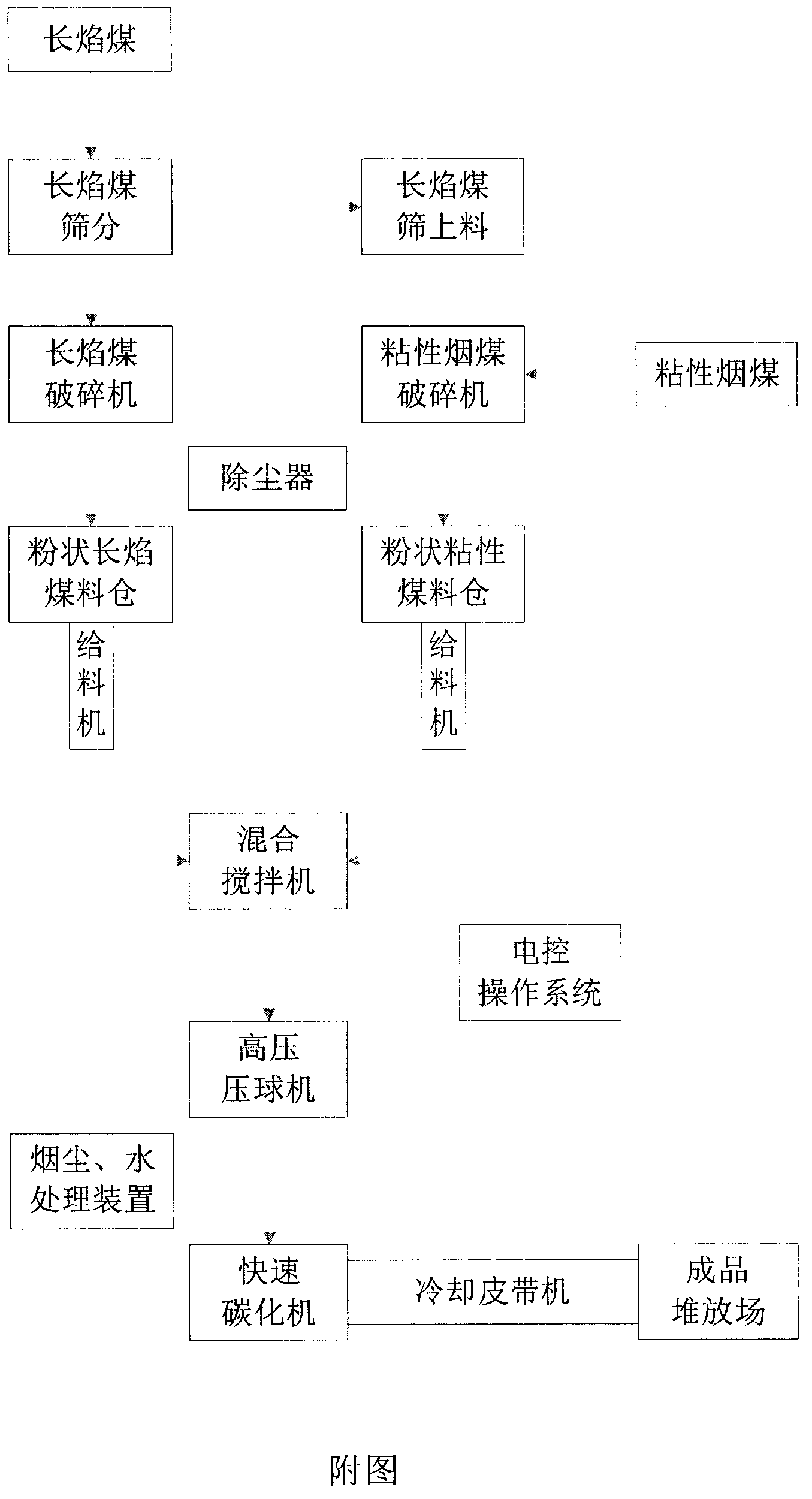

Image

Examples

Embodiment

[0019] After the long-flame coal is screened, the pulverized coal with a particle size of <5mm enters the long-flame coal crusher, and the pulverized coal is hit to the crushing plate by the high-speed rotating hammer, and is crushed to ≤1mm before being sent to the powdery long-flame coal silo; The viscous bituminous coal enters the viscous bituminous coal crusher, is hit by the high-speed rotating hammer head to the crushing plate, is crushed to ≤1mm, and then sent to the powdery viscous bituminous coal silo; Carry out purification and recovery; the feeder configured under the silo sends powdered long-flame coal and powdered viscous bituminous coal into the mixing mixer in a certain proportion and stirs evenly, and then sends them into the high-pressure briquetting machine with a heating device at 50-95°C , the line pressure of the high-pressure briquette machine to press the pulverized coal is 80-100KN / cm, and the pulverized coal is briquetted by high-pressure balls in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com