A method for producing exopolysaccharide of Inonotus obliquus by submerged liquid fermentation

A technology of Inonotus obliquus and extracellular polysaccharide, applied in the field of microorganisms, can solve the problems of low yield of active product extracellular sugar, high production cost, limitations and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method for producing Inonotus obliquus exopolysaccharide by industrialized deep liquid fermentation of the present invention is carried out according to the following steps:

[0032]1. Preparation of Inonotus obliquus fermented liquid: inoculate the shake flask bacterial strain of Inonotus obliquus well into seed culture medium (300L) by inoculum size 1%, wherein the seed culture medium consists of glucose 3%, silkworm chrysalis powder 0.3% , soybean cake powder 1.8%, potassium dihydrogen phosphate 0.3%, magnesium sulfate heptahydrate 0.15%, defoamer 0.02%, adjust the pH value to 7.0, the ventilation ratio is 1:0.3vvm, the tank pressure is 0.03Mpa, and shake at 26-28°C Cultivate for 5 days to get the primary seed liquid of Inonotus obliquus; insert the primary seed liquid into the secondary seed medium (3000L) according to the inoculum size 15%, wherein the secondary seed medium consists of 3% glucose and 0.3% silkworm chrysalis powder %, soybean cake powder 1.8%, p...

Embodiment 2

[0037] 1. Preparation of Inonotus obliquus fermented liquid: inoculate the shake flask strain of Inonotus obliquus well into seed culture medium (300L) by inoculum size 1.5%, wherein the seed culture medium consists of glucose 3%, silkworm chrysalis powder 0.3% , soybean cake powder 1.8%, potassium dihydrogen phosphate 0.3%, magnesium sulfate heptahydrate 0.15%, defoamer 0.02%, adjust the pH value to 7.0, the ventilation ratio is 1:0.3vvm, the tank pressure is 0.03Mpa, and shake at 25~27℃ Cultivate for 6 days to get the primary seed liquid of Inonotus obliquus; insert the primary seed liquid into the secondary seed medium (3000L) according to the inoculum size 15%, wherein the secondary seed medium consists of 3% glucose and 0.3% silkworm chrysalis powder %, soybean cake powder 1.8%, potassium dihydrogen phosphate 0.3%, magnesium sulfate heptahydrate 0.15%, defoamer 0.02%, adjust the pH value to 7.0, the ventilation ratio is 1:0.3vvm, the tank pressure is 0.03Mpa, 25~27℃ Culti...

Embodiment 3

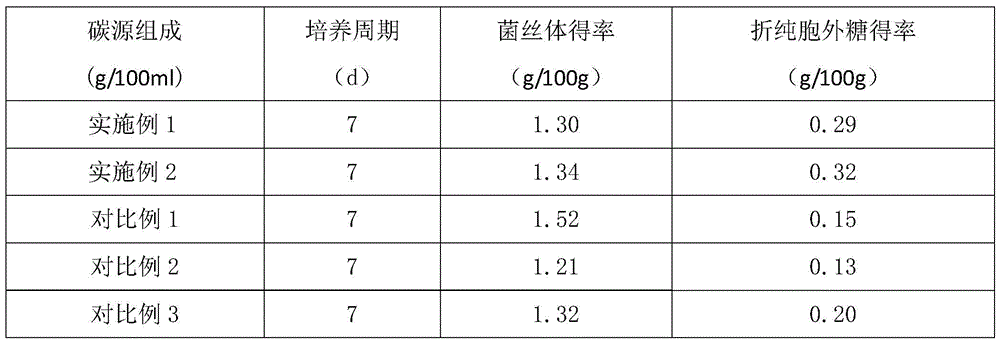

[0042] In order to better verify the superiority of the compound prescription of short-acting glucose and long-acting starch in the industrial production of Inonotus obliquus polysaccharides in the present invention, several comparative experiments were done. Only adjusted the consumption of carbon source glucose or (and) starch in the test in the liquid fermentation medium, do not contain starch in the comparative example 1, and the glucose concentration is 1.5%; Do not contain glucose in the comparative example 2, the starch concentration is 2.5%, to In ratio 3, the glucose content is 2.5%, and the starch content is 0.5%; all the other conditions are the same as in Example 1, and the test results are shown in Table 1:

[0043] Table 1

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com