Bauxite tailings-based iron ore pellet binder and preparation method thereof

A bauxite and binder technology, which is applied in the field of bauxite dressing tailings-based iron ore pellet binder and its preparation, to reduce land occupation and harm to the environment, good pelletizing performance, and The effect of improved compressive and abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

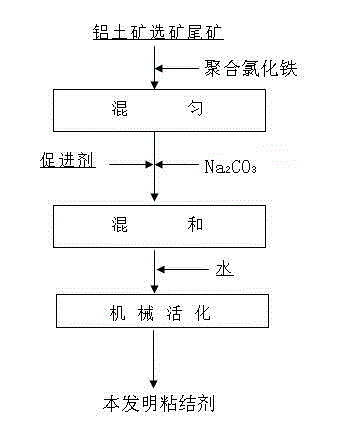

Image

Examples

Embodiment 1

[0024] An iron ore pellet binder prepared from bauxite beneficiation tailings as the main raw material is made of the following raw materials in weight percentage:

[0025] 80% bauxite beneficiation tailings, its aluminum-silicon ratio is 1.2, the slurry potential of 10% mass concentration is -225 mV, and the particle size is ≤0.074 mm;

[0026] Carboxymethylcellulose sodium 15%, pH 10, average molecular weight 10,000 Daltons, solution viscosity of 3% mass concentration 1800 mPa.s, particle size ≤ 0.074 mm;

[0027] Polyferric chloride 3%, particle size <0.074 mm;

[0028] Na 2 CO 3 2%.

[0029] The preparation method of the above-mentioned binder comprises the following steps: first mix the polyferric chloride and the bauxite beneficiation tailings evenly, and then add carboxymethylcellulose sodium and Na 2 CO 3 Mix well, then add water to perform ball milling mechanical activation treatment; the high-energy ball milling speed is 600 r / min, the ball-to-material ratio is...

Embodiment 2

[0032] An iron ore pellet binder prepared from bauxite beneficiation tailings as the main raw material is made of the following raw materials in weight percentage:

[0033] Bauxite beneficiation tailings are 75%, its aluminum-silicon ratio is 1.0, the slurry potential of 10% mass concentration is -245 mV, and the particle size is <0.074 mm;

[0034] Carboxymethylcellulose sodium 15%, pH 10, average molecular weight 10,000 Daltons, solution viscosity of 3% mass concentration 1800 mPa.s, particle size ≤ 0.074 mm;

[0035] Polyferric chloride 5%, particle size <0.074 mm;

[0036] Na 2 CO 3 5%.

[0037] The preparation method of the above-mentioned binder comprises the following steps: first mix the polyferric chloride and the bauxite beneficiation tailings evenly, and then add carboxymethylcellulose sodium and Na 2 CO 3 Mix well, then add water for mechanical activation by ball milling; the high-energy ball milling speed is 800 r / min, the ball-to-material ratio is 30%, the ...

Embodiment 3

[0040] An iron ore pellet binder prepared from bauxite beneficiation tailings as the main raw material is made of the following raw materials in weight percentage:

[0041] 80% bauxite beneficiation tailings, its aluminum-silicon ratio is 1.2, the slurry potential of 10% mass concentration is -225 mV, and the particle size is <0.074 mm;

[0042] Humic acid 15%, pH 9.5, average molecular weight 15000 Daltons, solution viscosity of 3% mass concentration is 2100 mPa.s, particle size ≤ 0.074 mm;

[0043] Polyferric chloride 3%, particle size <0.074 mm;

[0044] Na 2 CO 3 2%.

[0045] The preparation method of the above-mentioned binder comprises the following steps: first mix the polyferric chloride and the bauxite beneficiation tailings evenly, and then add humic acid and Na 2 CO 3 Mix well, then add water to perform ball milling mechanical activation treatment; wherein the high-energy ball milling speed is 800r / min, the ball-to-material ratio is 50%, the activation time is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com