Pipe for aluminum alloy drilling rod of deep and ultra-deep wells and manufacturing method thereof

A manufacturing method and technology for ultra-deep wells, which are applied in drill pipes, drill pipes, casings, etc., can solve the problems of high production cost, long supply cycle and complex production process, achieve high strength and toughness, simplify production process, and reduce environment. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

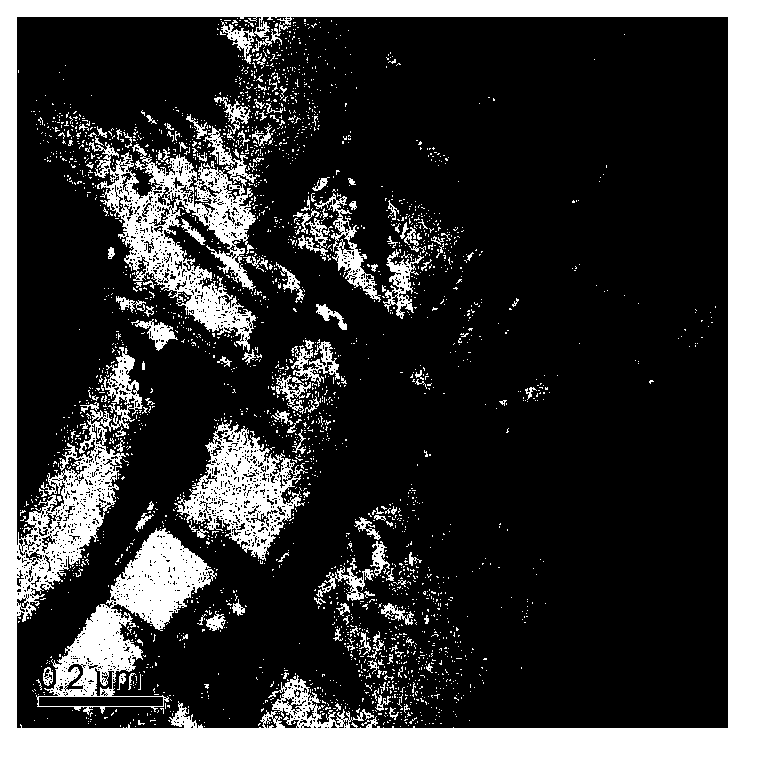

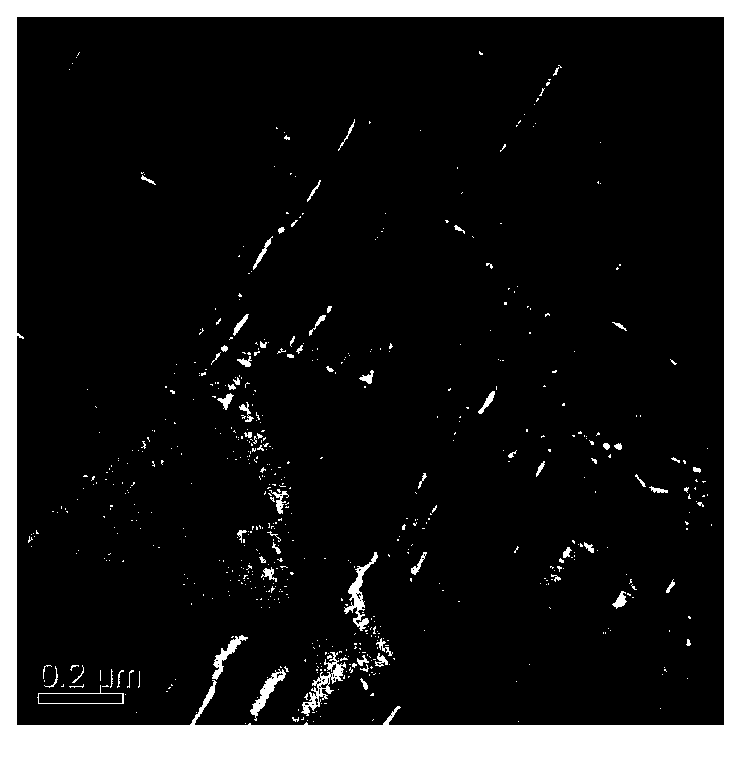

[0038] Embodiment 1: as figure 1 , figure 2 , image 3 as shown,

[0039] An aluminum alloy drill pipe body for deep and ultra-deep wells and a manufacturing method thereof,

[0040] The invention provides an aluminum alloy drill pipe body for deep and ultra-deep wells, which is composed of (mass percentage): Cu4.9%, Mg1.8%, Mn1.1%, Ti0.05%, Zn0.5%, B0 .005%, Yb0.02%, the balance is Al and unavoidable impurities.

[0041] The above-mentioned tube blank is homogenized at 480°C, extruded at 420°C, solid solution quenched at 485°C×1h+495°C×1h, air-cooled and aged to room temperature naturally.

[0042] The mechanical properties of the aluminum alloy treated by the above method reach: the tensile strength is 505MPa, the yield strength is 367MPa, and the elongation is 13.5%. 311MPa, elongation 12.3%. Its performance index fully meets the requirements of ISO15546 standard for aluminum alloy drill pipe body. In this example, after heat exposure at 120°C for 500h, the structur...

example 12

Embodiment 2

[0044] The invention provides an aluminum alloy drill pipe body for deep and ultra-deep wells, which is composed of (mass percentage): Cu5.2%, Mg1.6%, Mn1.0%, Ti0.05%, Zn0.5%, B0 .005%, Yb0.05%, the balance is Al and unavoidable impurities.

[0045] The above-mentioned tube blank is homogenized at 490°C, extruded at 435°C, solid solution quenched at 490°C×1h+505°C×1h, air-cooled and aged to room temperature naturally.

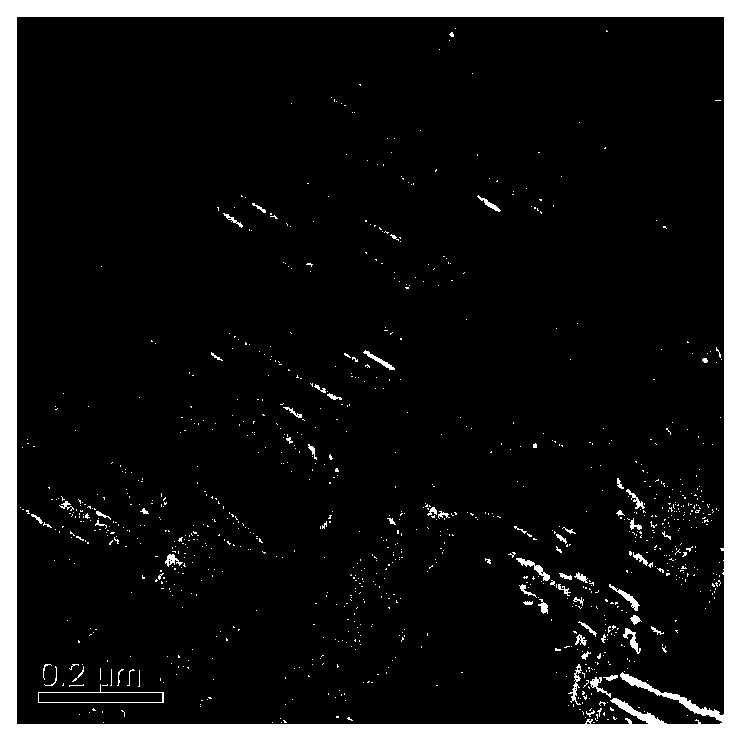

[0046] The mechanical properties of the aluminum alloy treated by the above method reach: the tensile strength is 517MPa, the yield strength is 407MPa, and the elongation is 13.0%. 317MPa, elongation 13.0%. Its performance index fully meets the requirements of ISO15546 standard for aluminum alloy drill pipe body. In this example, after heat exposure at 160°C for 500h, the structure of the transmission electron microscope can be seen figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com