A papermaking method for producing thin steel paper from waste paper slag

A technology of steel paper and waste paper, which is applied in the production of thin steel paper, which can solve the problems of insufficient bonding force between layers of steel paper sheets, poor paper strength, smoothness and wear resistance, etc., and improve the retention rate , Improve the binding force, improve the effect of ring pressure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

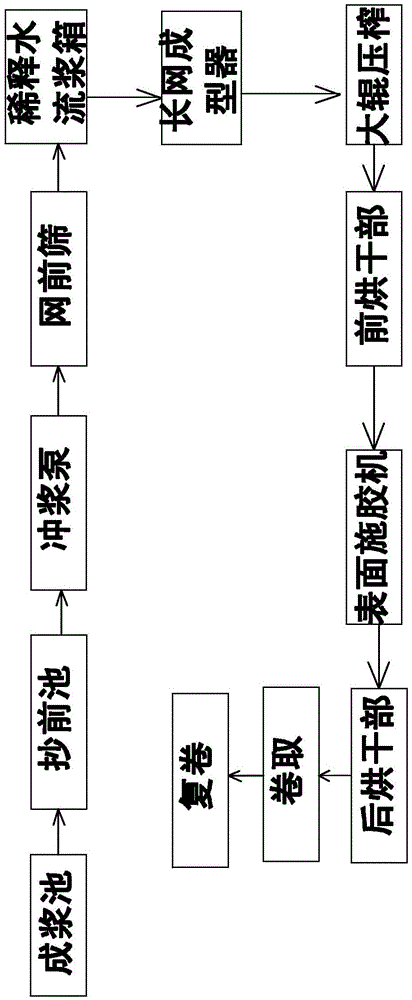

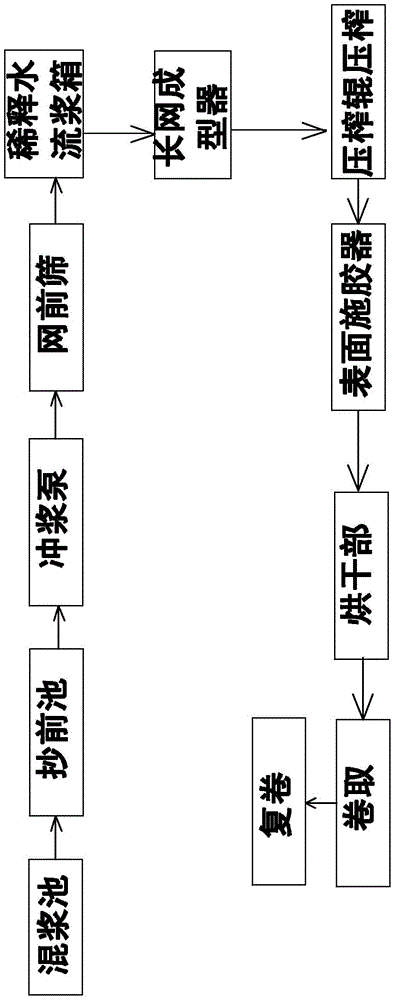

[0018] Such as figure 2 , Embodiment 1 of the present invention discloses a papermaking method for producing thin steel paper from waste paper, including the step of pulping in the pulp mixing tank and the step of papering the adjusted mixed pulp fibers into thin steel paper sheets. The paper making is to send the mixed pulp fibers from the mixing tank to the dilution water headbox after passing through the forebay, the flushing pump, and the front screen; the dilution water headbox then sprays the mixed pulp fibers to the fourdrinier former Dehydration forming is carried out on the fourdrinier former; the wet paper sheet coming out of the fourdrinier former is pressed and dehydrated by pressing rollers, and the semi-dry paper sheet after pressing enters the surface sizing machine for double-sided sizing, and the surface sizing agent is gelatinized Modified starch, the amount of modified starch added is 2.0% of the absolute dry pulp, the concentration of modified starch added...

Embodiment 2

[0024] Such as figure 2 , Embodiment 2 of the present invention discloses a papermaking method for producing thin steel paper from waste paper, including the step of pulping in the pulp mixing tank and the step of papering the adjusted mixed pulp fibers into thin steel paper sheets. The paper making is to send the mixed pulp fibers from the mixing tank to the dilution water headbox after passing through the forebay, the flushing pump, and the front screen; the dilution water headbox then sprays the mixed pulp fibers to the fourdrinier former Dehydration forming is carried out on the fourdrinier former; the wet paper sheet coming out of the fourdrinier former is pressed and dehydrated by pressing rollers, and the pressed semi-dry paper sheet enters the surface sizing machine for double-sided sizing, and the surface sizing agent adopts gelatinization modified starch, the amount of modified starch added is 3.0% of the absolute dry pulp, the concentration of modified starch added...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com