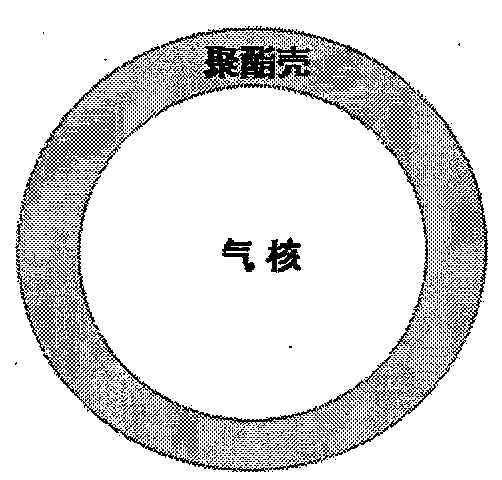

Novel preparation process for polyester hard-shell microbubble system with controllable particle size

A microbubble and system technology, applied in the direction of echo/ultrasonic imaging agents, etc., can solve the problems of complex preparation process, poor stability of soft-shell microbubbles, poor shell compressibility, etc., and achieve easy separation and purification, good biological Effects of compatibility and safety, good prospects for biomedical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

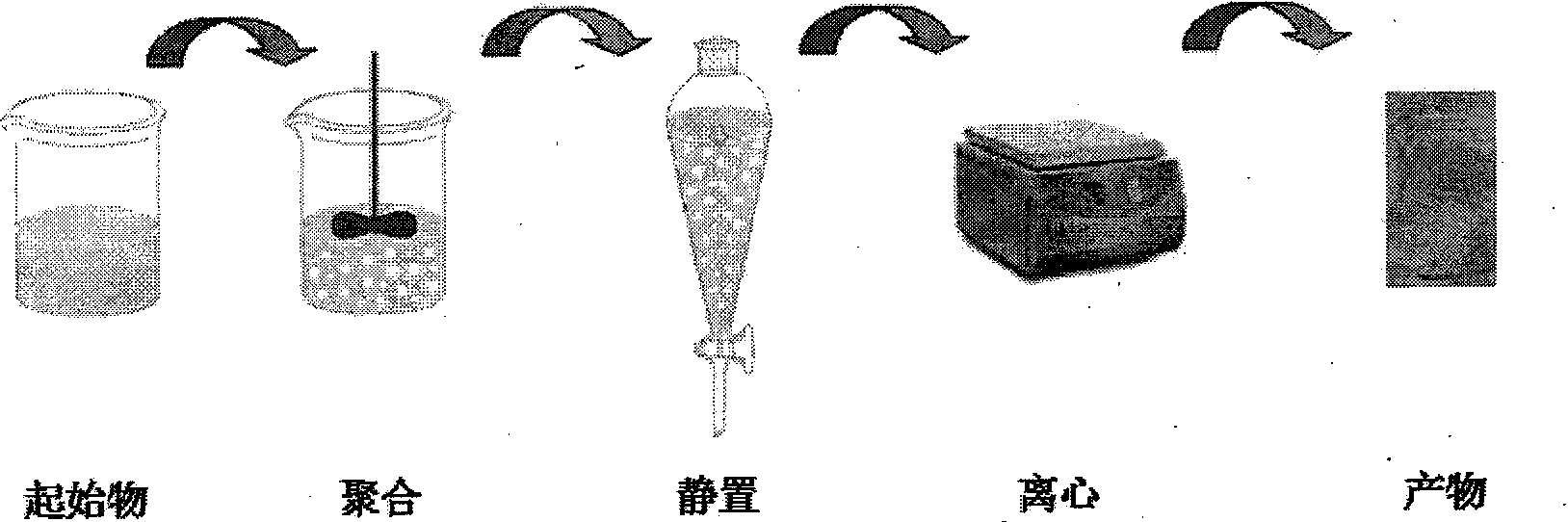

Embodiment 1

[0028] Example 1: N-butyl acrylate, polyethylene glycol octylphenyl ether, and high-purity deionized water were fed into a 2-liter beaker at a ratio of 1:1:100, and the pH value of the reaction system was adjusted to weak acidity (about 2.5 ), stirred at a high speed (rpm=10000) at room temperature for 60 minutes, and after the reaction was terminated, the crude product was transferred to a separatory funnel and left to stand for 5 hours, the bottom layer residue was discarded, and the top layer of microbubbles were kept, and mixed with 0.02% polyethylene glycol Octylphenyl ether aqueous solution was washed three times. The obtained product was divided into centrifuge tubes, purified and centrifuged for 20 minutes, and the microbubble product layer on the top layer of the centrifuge tube was carefully collected, and the microbubble layer was combined after repeated centrifugation three times, and redispersed into 0.02% polyethylene glycol octylphenyl ether aqueous solution Sto...

Embodiment 2

[0029] Example 2: N-butyl acrylate, polyethylene glycol octylphenyl ether, and high-purity deionized water are fed into a 2-liter beaker at a ratio of 1:1:100, and the pH value of the reaction system is adjusted to weak acidity (about 2.5 ), stirred at a high speed (rpm=8000) at room temperature for 60 minutes, and after the reaction was terminated, the crude product was transferred to a separatory funnel and left to stand for 5 hours, the residue at the bottom was discarded, and the top layer of microbubbles was kept, and mixed with 0.02% polyethylene glycol Octylphenyl ether aqueous solution was washed three times. The obtained product was divided into centrifuge tubes, purified and centrifuged for 20 minutes, and the microbubble product layer on the top layer of the centrifuge tube was carefully collected, and the microbubble layer was combined after repeated centrifugation three times, and redispersed into 0.02% polyethylene glycol octylphenyl ether aqueous solution Stored...

Embodiment 3

[0030] Embodiment 3: N-butyl acrylate, polyethylene glycol octyl phenyl ether, and high-purity deionized water are fed into a 2-liter beaker at a ratio of 1:1:100, and the pH value of the reaction system is adjusted to weak acidity (about 2.5 ), stirred at a high speed (rpm=4000) at room temperature for 60 minutes, and after the reaction was terminated, the crude product was transferred to a separatory funnel and left to stand for 5 hours, the residue at the bottom was discarded, and the top layer of microbubbles was kept, and mixed with 0.02% polyethylene glycol Octylphenyl ether aqueous solution was washed three times. The obtained product was divided into centrifuge tubes, purified and centrifuged for 20 minutes, and the microbubble product layer on the top layer of the centrifuge tube was carefully collected, and the microbubble layer was combined after repeated centrifugation three times, and redispersed into 0.02% polyethylene glycol octylphenyl ether aqueous solution St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com