Plasma and pulse discharge composite polishing processing device for large complex metal surfaces

A technology of pulse discharge and plasma, which is applied in the field of plasma and pulse discharge combined polishing processing equipment, can solve the problems of harmful radiation and toxic reaction gas, expensive equipment, limited use range, etc., to achieve processing and High polishing efficiency, high processing efficiency, and the effect of cheap polishing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

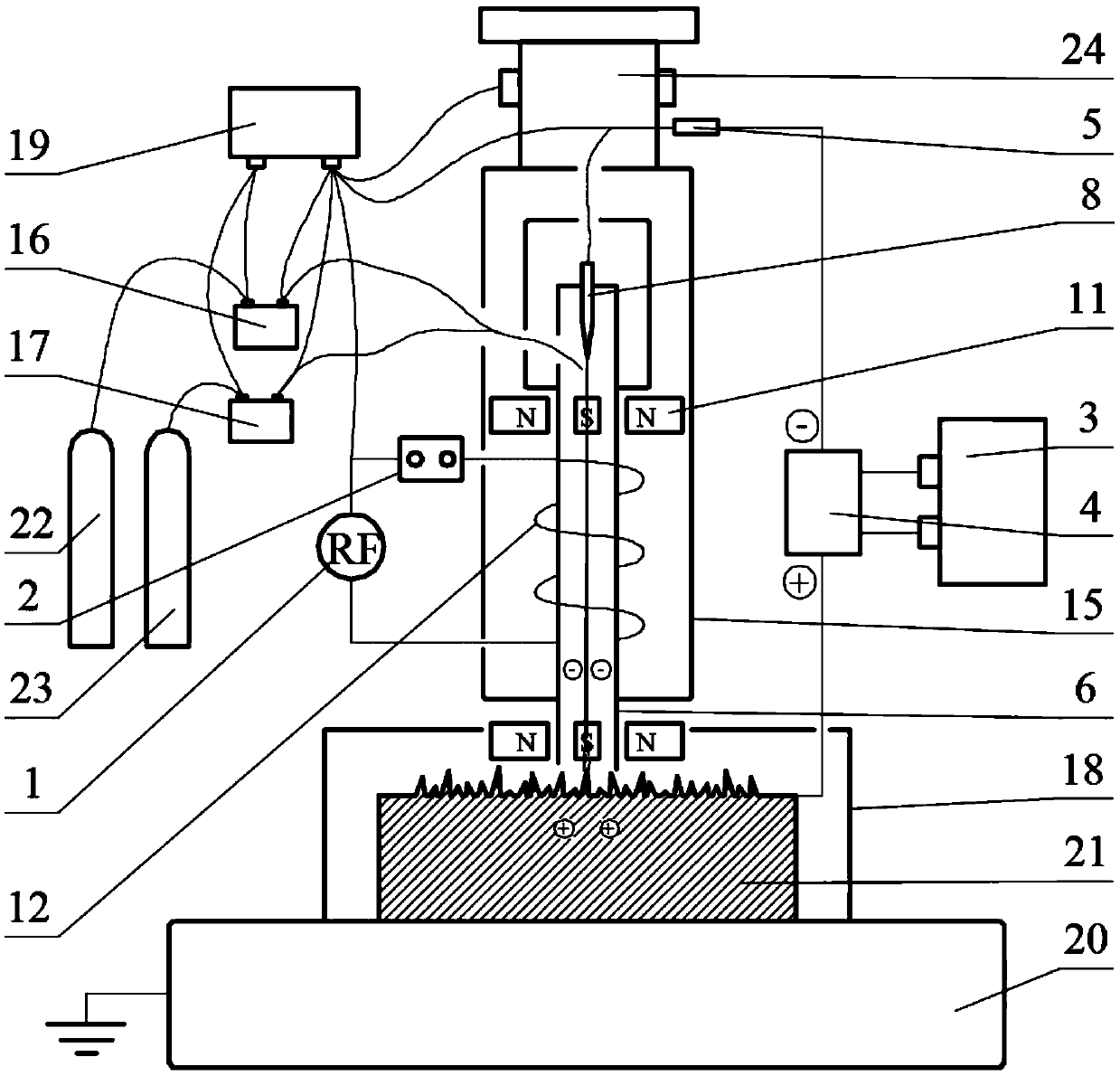

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

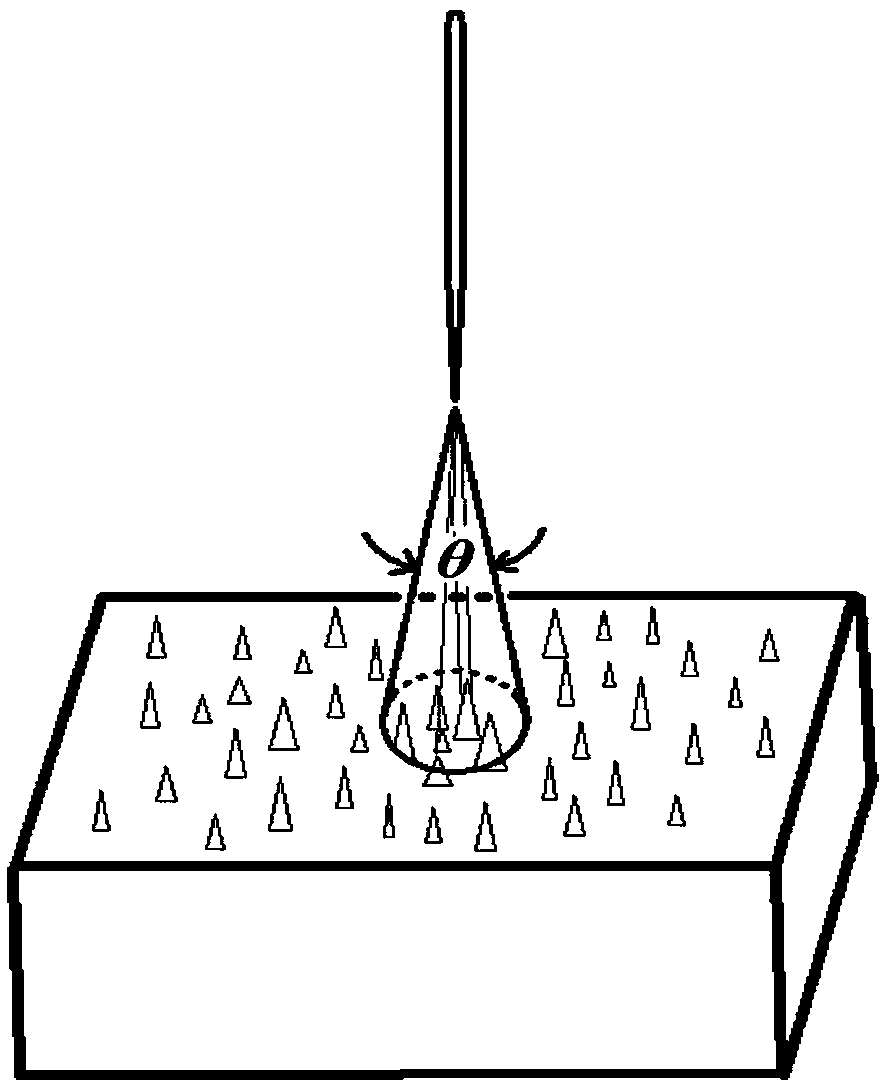

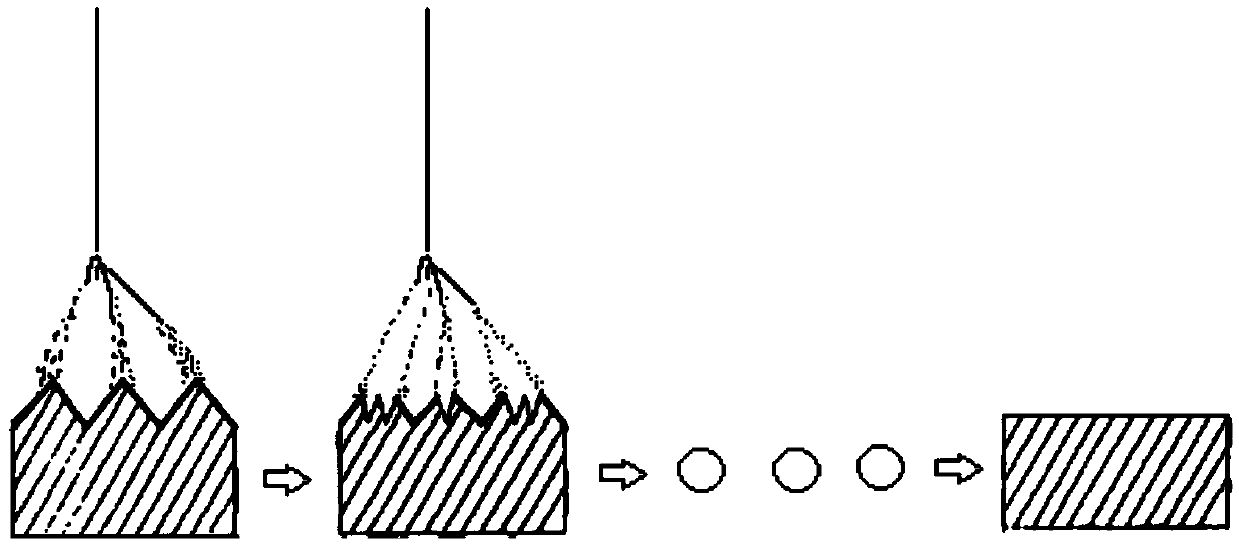

[0029] The invention realizes the pulse discharge through a radio frequency power supply, a high-voltage DC pulse power supply with adjustable output voltage, and needle-shaped discharge electrodes with variable length and section. The output pole of the high-voltage DC pulse power supply is connected to a discharge electrode and the metal material processing workpiece to be polished. The radio frequency power supply realizes radio frequency oscillation to generate a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com